Loading ...

Loading ...

Loading ...

I Installation Instructions R410-A Split System Condensers I

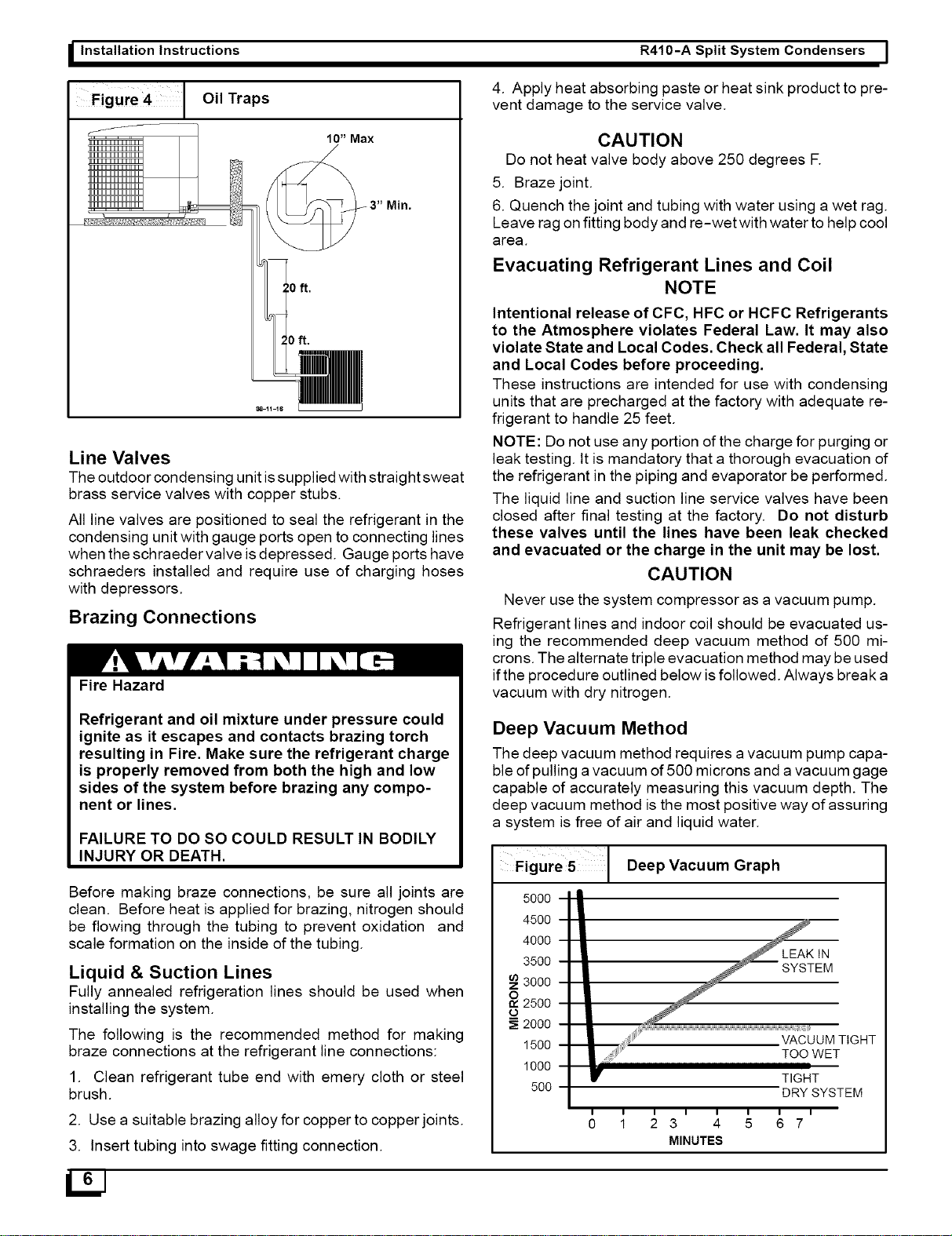

Figure 4 I Oil Traps

10" Max

Min.

Line Valves

The outdoor condensing unit issupplied with straight sweat

brass service valves with copper stubs.

All line valves are positioned to seal the refrigerant in the

condensing unit with gauge ports open to connecting lines

when the schraeder valve is depressed. Gauge ports have

schraeders installed and require use of charging hoses

with depressors.

Brazing Connections

Fire Hazard

Refrigerant and oil mixture under pressure could

ignite as it escapes and contacts brazing torch

resulting in Fire. Make sure the refrigerant charge

is properly removed from both the high and low

sides of the system before brazing any compo-

nent or lines.

FAILURE TO DO SO COULD RESULT IN BODILY

INJURY OR DEATH.

Before making braze connections, be sure all joints are

clean. Before heat is applied for brazing, nitrogen should

be flowing through the tubing to prevent oxidation and

scale formation on the inside of the tubing.

Liquid & Suction Lines

Fully annealed refrigeration lines should be used when

installing the system.

The following is the recommended method for making

braze connections at the refrigerant line connections:

1. Clean refrigerant tube end with emery cloth or steel

brush.

2. Use a suitable brazing alloy for copper to copper joints.

3. Insert tubing into swage fitting connection.

4. Apply heat absorbing paste or heat sink product to pre-

vent damage to the service valve.

CAUTION

Do not heat valve body above 250 degrees F.

5. Braze joint.

6. Quench the joint and tubing with water using a wet rag.

Leave rag on fitting body and re-wet with water to help cool

area.

Evacuating Refrigerant Lines and Coil

NOTE

Intentional release of CFC, HFC or HCFC Refrigerants

to the Atmosphere violates Federal Law. It may also

violate State and Local Codes. Check all Federal, State

and Local Codes before proceeding.

These instructions are intended for use with condensing

units that are precharged at the factory with adequate re-

frigerant to handle 25 feet.

NOTE: Do not use any portion of the charge for purging or

leak testing. It is mandatory that a thorough evacuation of

the refrigerant in the piping and evaporator be performed.

The liquid line and suction line service valves have been

closed after final testing at the factory. Do not disturb

these valves until the lines have been leak checked

and evacuated or the charge in the unit may be lost.

CAUTION

Never use the system compressor as a vacuum pump.

Refrigerant lines and indoor coil should be evacuated us-

ing the recommended deep vacuum method of 500 mi-

crons. The alternate triple evacuation method may be used

if the procedure outlined below is followed. Always break a

vacuum with dry nitrogen.

Deep Vacuum Method

The deep vacuum method requires a vacuum pump capa-

ble of pulling a vacuum of 500 microns and a vacuum gage

capable of accurately measuring this vacuum depth. The

deep vacuum method is the most positive way of assuring

a system is free of air and liquid water.

Figure 5

5000

4500

4000

3500

3000

2500

o

2000

1500

1000

50O

Deep Vacuum Graph

LEAKIN

SYSTEM

VACUUM TIGHT

TOO WET

TIGHT

DRY SYSTEM

0 1 23 4 5 67

MINUTES

Loading ...

Loading ...

Loading ...