Loading ...

Loading ...

Loading ...

• Keepyouedgingpathstraightbyaligning

thebladeguideribontherearoftheblade

guardwiththeedgeofthesidewalk.Keep

allwheelsflatonthewalkway.

• Alwaysworkgoingawayfrompeopleand

solidobjectssuchaswalls,largestones,

trees,automobiles,etc.

• Becarefulwhenedgingneartreesorvalu-

ableplants.Thehighspeedmetalblade

maycutrootsandcausedamagetothe

plants.

• Ifthebladestalls,immediatelymovethe

unitrearwardslightlytoallowthebladeto

restart.Ifthebladecontinuestostall,stop

theengine,disconnectthesparkplug,and

inspectforblockageordamage.

• Alwayskeepthebladeareaclean.Stopthe

engine,makesurethebladehascomplete-

lystoppedturning,anddisconnectthe

sparkplugbeforecleaning.

SETTING THE EDGING DEPTH

_,WARNING: Never attempt to adjust

the depth adjusting skid when the engine is

running. Always release the throttle trigger,

wait until the blade stops turning, move the

ON/OFF switch to the OFF position, and dis-

connect spark plug before making adjust-

ments. Your edger is equipped with several

edging depths. The depth used will depend

on your personal edging preference and the

condition of the area where the edging opera-

tion is to be done.

NOTE: If the area to be edged has never

been cut or several weeks have passed since

the last cut, the first edging should be done at

no more than half depth.

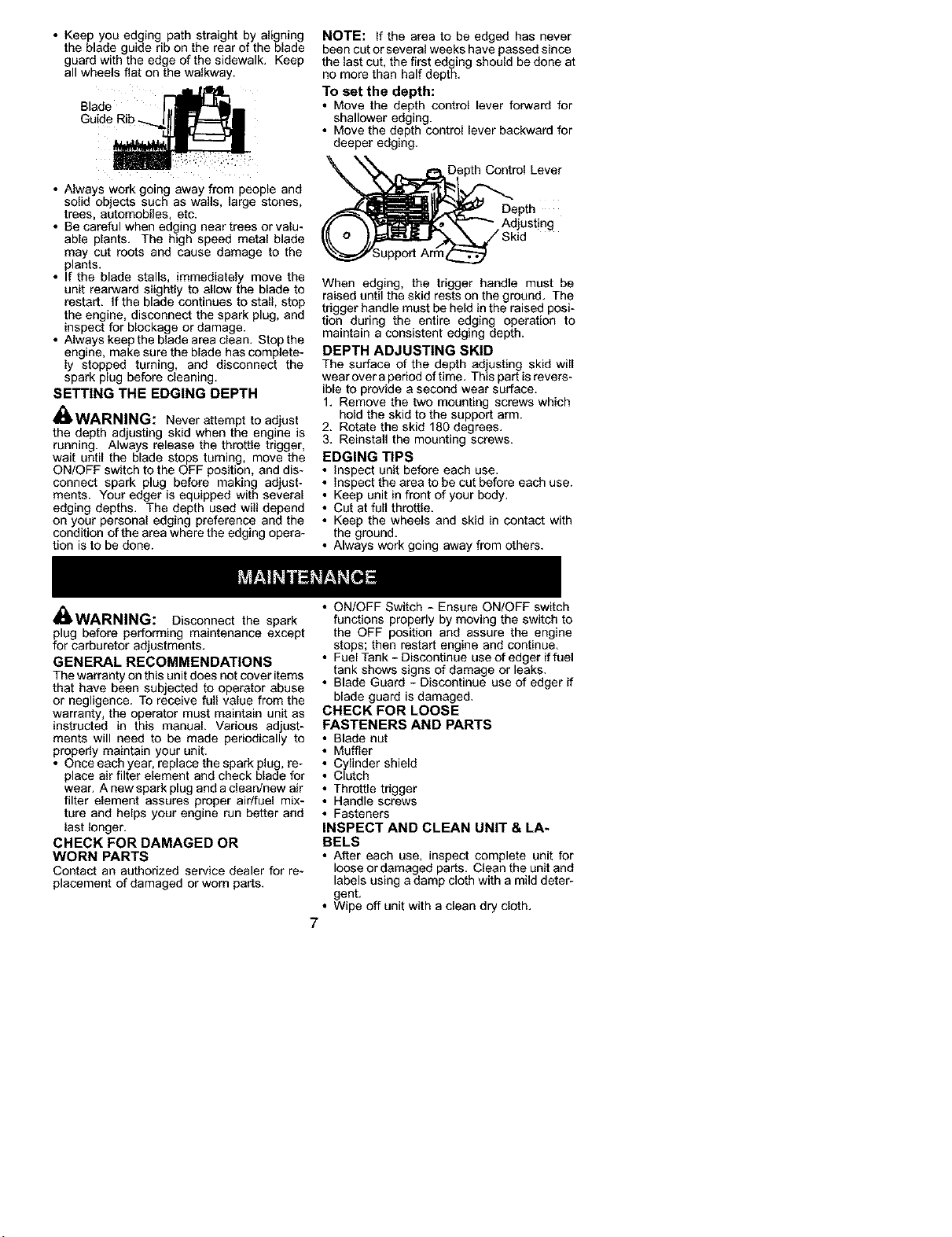

To set the depth:

• Move the depth control lever forward for

shallower edging.

• Move the depth control lever backward for

deeper edging.

Control Lever

Depth

Adjusting

When edging, the trigger handle must be

raised until the skid rests on the ground, The

trigger handle must be held in the raised posi-

tion during the entire edging operation to

maintain a consistent edging depth.

DEPTH ADJUSTING SKID

The surface of the depth adjusting skid will

wear over a period of time, This part is revers-

ible to provide a second wear surface.

1, Remove the two mounting screws which

hold the skid to the support arm.

2. Rotate the skid 180 degrees.

3, Reinstall the mounting screws.

EDGING TIPS

• Inspect unit before each use,

• Inspect the area to be cut before each use.

• Keep unit in front of your body.

• Cut at full throttle.

• Keep the wheels and skid in contact with

the ground.

• Always work going away from others.

,t=

DWARNING: Disconnect the spark

plug before performing maintenance except

for carburetor adjustments.

GENERAL RECOMMENDATIONS

The warranty on this unit does not cover items

that have been subjected to operator abuse

or negligence. To receive full value from the

warranty, the operator must maintain unit as

instructed in this manual. Various adjust-

ments will need to be made periodically to

properly maintain your unit.

• Once each year, replace the spark plug, re-

place air filter element and check blade for

wear. A new spark plug and a clean/new air

filter element assures proper air/fuel mix-

ture and helps your engine run better and

last longer.

CHECK FOR DAMAGED OR

WORN PARTS

Contact an authorized service dealer for re-

placement of damaged or worn parts.

• ON/OFF Switch - Ensure ON/OFF switch

functions properly by moving the switch to

the OFF position and assure the engine

stops; then restart engine and continue,

• Fuel Tank - Discontinue use of edger if fuel

tank shows signs of damage or leaks.

• Blade Guard - Discontinue use of edger if

blade guard is damaged.

CHECK FOR LOOSE

FASTENERS AND PARTS

Blade nut

Muffler

Cylinder shield

Clutch

Throttle trigger

Handle screws

Fasteners

INSPECT AND CLEAN UNIT & LA-

BELS

• After each use, inspect complete unit for

loose ordamaged parts. Clean the unit and

labels using a damp cloth with a mild deter-

gent.

• Wipe oft unit with a clean dry cloth.

7

Loading ...

Loading ...

Loading ...