Loading ...

Loading ...

Loading ...

6

Automatic Operation:

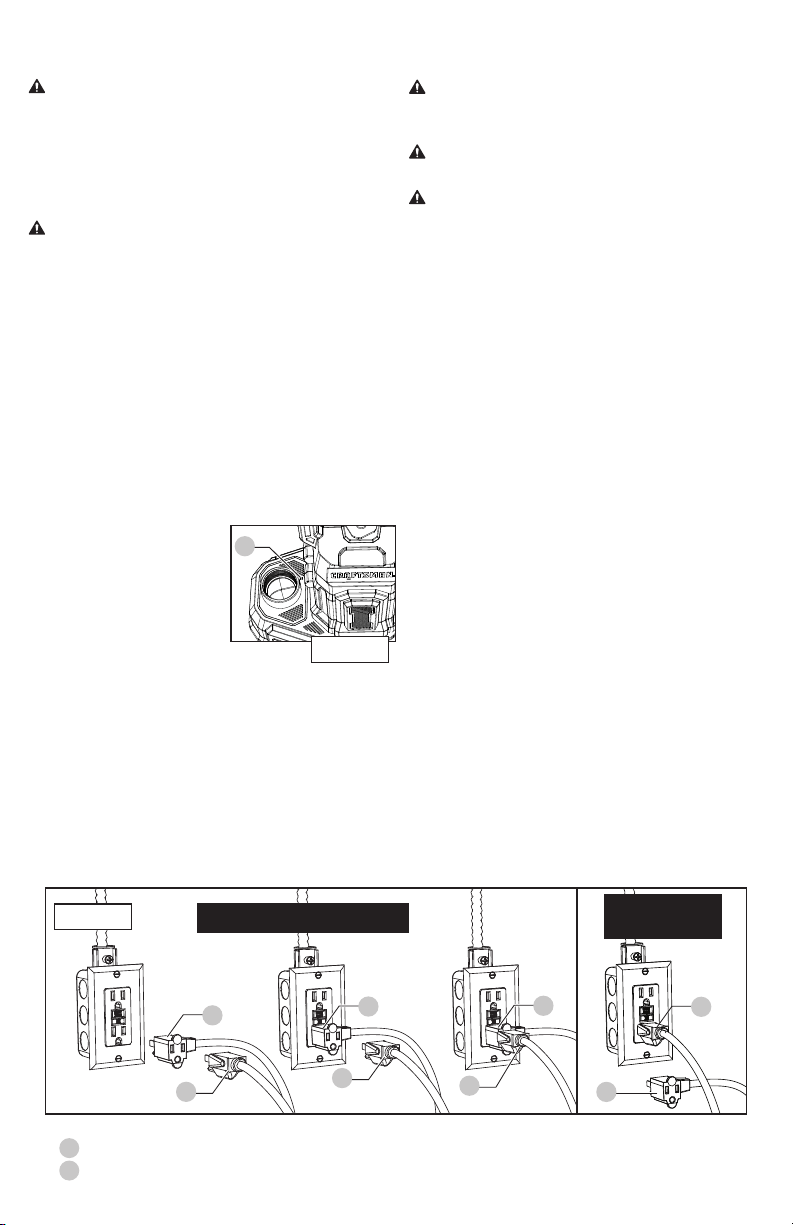

1. Connect the piggy-back plug of the float switch into a

115 volt grounded GFCI receptacle. See Figure 2.

2. Connect the pump plug into the back of the piggy-back

float switch plug. See Figure 2.

3. Test your installation by filling the basin with water.

Observe the float switch through at least one complete

cycle to ensure it operates freely and does not contact

the sides of the basin. If necessary, adjust the float switch

or reposition the pump to ensure proper operation.

4. This pump is equipped with

an (A) anti-airlock hole. A

stream of water will emit from

this hole when the pump is

operating. This is a normal

feature of this pump. The

anti-airlock hole should be

cleaned periodically to prevent the pump

from becoming air locked. See Figure 3

Manual Operation:

1. For manual operation or float switch failure, the pump

power cord can be disconnected from the piggy-

back float switch plug and connected directly to the

receptacle. This will bypass the float switch and the

pump will run continuously. During manual operation

the pump should be monitored at all times to ensure

the pump does not run dry. When pumping is complete

disconnect from receptacle.

1. The pump motor is hermetically sealed in the housing

and does not require any service. Disassembly of the

motor housing or modification of the power cord voids

the warranty.

2. Periodically check the sump basin for accumulation of

mud, silt, sand and foreign objects. Clean the basin as

needed to prevent damage or clogging of the pump.

3. Periodically check the intake for obstructions. Clean if

necessary.

4. Periodically inspect and clean the anti-airlock hole.

5. Inspect the float switch for any accumulated sediment or

debris that may inhibit it from operating properly. Clean

if necessary.

6. Inspect the power cord for signs of damage or wear. Do

not operate the pump if the cord is damaged or worn.

7. In applications where the pump may not activate for

extended periods of time, it is recommended to cycle the

pump at least once per month to ensure the pumping

system is working properly when needed.

Maintenance

WARNING: Risk of electric shock. Always disconnect

the power supply before attempting to install, service or perform

maintenance on the pump.

WARNING: All repairs must be made by a qualified

technician.

CAUTION: This submersible pump contains oil which may

become pressurized and hot under normal operating conditions

– allow the pump to cool for 2-3 hours before servicing.

Components

1 Float Switch Plug

2 Pump Plug

ENGLISH

Operation

WARNING: The pump motor is thermally protected. It is

not recommended for pumping liquids over 120° F (48.9°C). The

thermal overload protector will automatically shut down the

pump in an overheat situation. The pump will reset itself once the

pump cools down. This overload is designed as a safety device

and it will fail after repeated use. Normal operation is for fluids

between 35° F - 120° F (1.7°C - 48.9°C).

WARNING: Do not let the pump run dry. This pump relies

on water for lubrication and cooling. Operating the pump without

water may cause the motor to overheat or cause damage to

internal parts. It may also shorten the life of your pump.

1

Step 1* Step 2* Step 3*

1

1

2

2

2

2

1

*Properly grounded GFCI

protected receptacle

Automatic Operation

Manual

Operation

Figure 2

A

Figure 3

Loading ...

Loading ...

Loading ...