Loading ...

Loading ...

Loading ...

76

Important!

Blower tubes and the intake cover must be installed

while adjusting engine idle! Engine idle speed will

also be affected if either the intake cover or blower

tubes are blocked, damaged or incorrectly installed!

Stopping the Engine

Cool the engine by allowing it to run at idle for 2 to 3 minutes.

Stop the engine by pulling the ignition switch.

Important!

If the engine continues to run while pulling the

ignition switch, stop the engine by pulling the choke

control out to the fully closed position. A clean and

unrestricted airflow is essential to your blower’s

engine performance and durability!

Before attempting any carburettor adjustments, inspect and clean

the engine air cleaner as described under the heading ‘Every 10

Hours’, on Page 6 of this manual.

Using the machine

Think Safety!

In the hands of an experienced operator, the machine can efficiently

move a wide variety of debris ranging from grass clippings to gravel.

As a general rule, try to operate your engine at the lowest throttle

setting necessary to get the job done:

Use low throttle settings when clearing lightweight materials from

around lawns or shrubbery.

Use medium to higher throttle settings to move lightweight grass or

leaves from parking lots or walkways.

Use full throttle when moving heavy loads such as dirt or snow.

User Information!

Noise increases at higher throttle settings! Always use the lowest

throttle setting required to get the job done!

Safe operation

Machine noise increases at higher throttle settings! Always use the

lowest throttle setting required to get the job done!

Never operate the blower when visibility is poor.

Always wear eye protection such as face shield or goggles while

operating this machine.

Wear a dust mask to reduce the risk of inhalation injuries.

Wear close fitting clothing to protect your legs and arms.

Wear hearing protection when operating this machine.

Never operate the blower if any component parts are damaged,

loose, or missing.

1. Using the blower

Always be aware of the strength and

direction of stream. Never direct the

blower discharge stream toward

people or animals.

Routine Maintenance

Warning!

Before performing any maintenance on this

blower, stop the engine and disconnect the spark

plug wire!

Daily Maintenance

Remove dirt and debris from the blower exterior.

Inspect the engine, tank, and hoses for possible fuel leaks, and

repair as necessary.

Inspect the engine cooling fins for accumulations of dirt or debris,

and clean as necessary.

Important!

Dirty or damaged cooling system components

may allow the engine to overheat, possibly

causing serious engine damage!

Important!

Operating the blower with loose, missing, or

damaged components could allow the engine

to over speed, possibly causing serious engine

damage!

Inspect the entire blower for damage, loose or missing components

or fastenings, and repair as necessary.

EVERY 10 HOURS

More frequently in dusty conditions.

Air

cleaner

cover

Cover

retaining

screw

Air

cleaner

element

Loosen the air cleaner cover retaining screw,

and remove the cover and filter element.

Inspect the element. If the element is distorted

or damaged, replace it with a new one.

Wash the element in clean fuel, and squeeze

or blow dry. Wash the air cleaner cover in

clean fuel, and wipe air blow dry.

Install the element and cover and then tighten

the cover retaining screw.

Remove sparkplug

by turning anti-

clockwise.

EVERY 10/15 HOURS

Use the spark plug wrench to remove

the spark plug (turn counter-clockwise to

remove).

Clean and adjust the spark plug gap to

0.6-0.7mm. Replace any damaged or visi-

bly worn plug with the correct plug or it’s

equivalent

Install the spark plug finger tight in the

cylinder head, then tighten it firmly with the

spark plug wrench. If a torque wrench is

available, torque the spark plug to 148-165

inch pounds.

Important!

Never allow dirt or debris to enter the cylinder

bore!Before removing the spark plug, thoroughly

clean the spark plug and cylinder head area!Allow

the engine to cool before servicing the spark plug!

Cylinder tightening or loosening the spark plug

while the engine is hot can result in serious engine

damage! Incorrect spark plug installation can result

in serious engine damage!

EVERY 50 HOURS

More frequently if you notice reduced performance.

INSPECTION

Inspect the entire blower and tubes for damage, including loose or

missing components, and repair as necessary.

SPARK PLUG

Replace the spark plug with a Champion RCJ6Y, gapped to (0.6-

0.7)mm.

FUEL FILTER

Fuel filter

Use a wire hook to extract the

fuel filter from inside the fuel

tank, and then remove and

wash the filter element in clean

fuel. Before reinstalling the filter,

inspect the condition of the fuel

line. If damage or deterioration is

noted, the blower should not be

used until it can be inspected by

a trained service technician.

COOLING SYSTEM

Remove the engine cover (as

described under ‘Spark Arrestor Maintenance), and use a wood or

plastic scraper and a soft brush to remove dirt and debris from the

cylinder fins and crankcase.

Spark Arrestor Maintenance

Hard starting or gradual loss of performance can be caused by

carbon deposits lodged in the spark arrestor screen. For maximum

performance, the spark arrestor screen should be periodically

cleaned as follows:

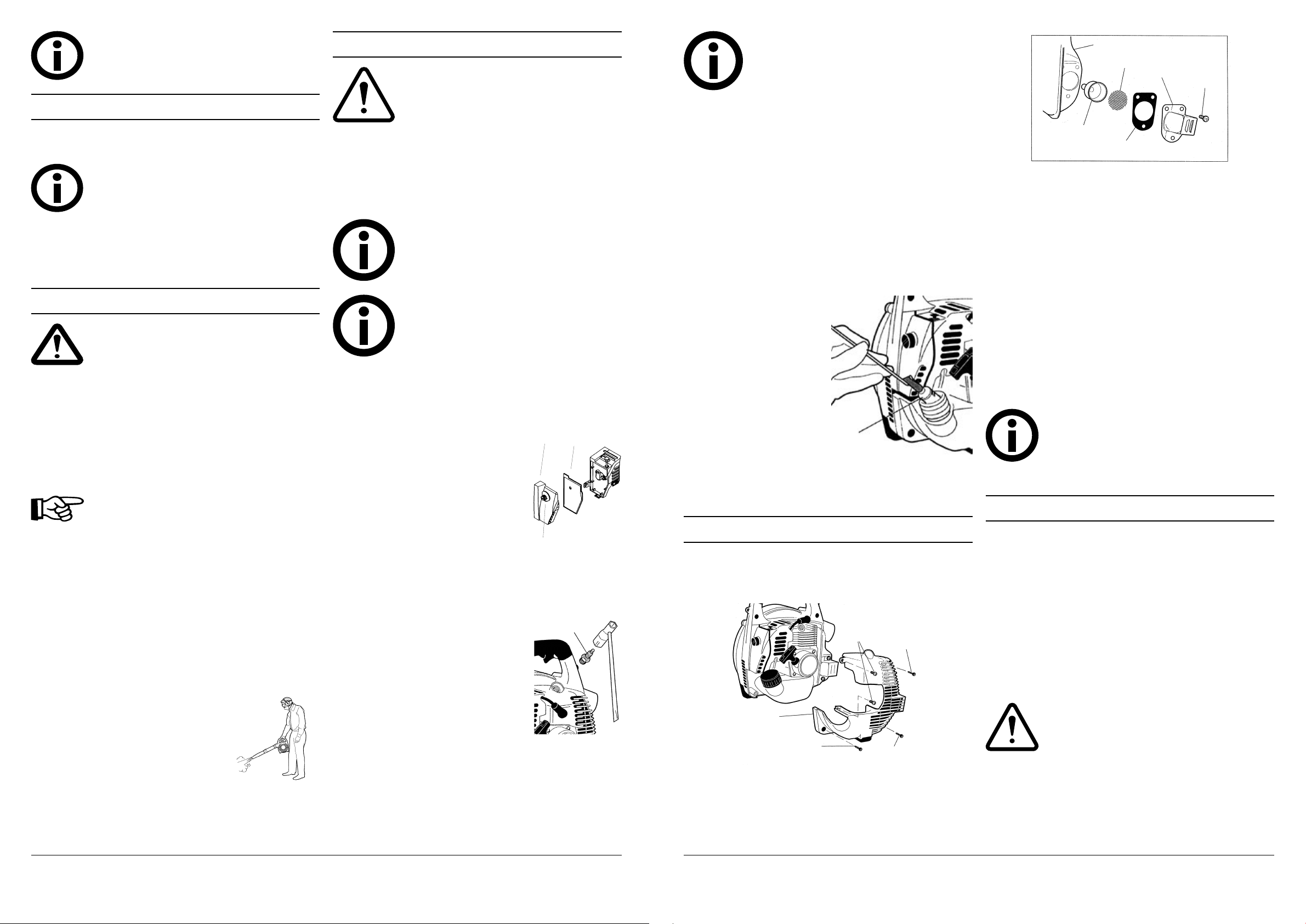

Remove the

engine cover

Self tapping

screw

Spark

arrestor

screen

Spark

arrestor

chamber

Spark

arrestor

cover

Retaining

screw

Gasket

Self tapping

screw

Self tapping

screw

Machine

screws

Remove the

engine cover

Self tapping

screw

Spark

arrestor

screen

Spark

arrestor

chamber

Spark

arrestor

cover

Retaining

screw

Gasket

Self tapping

screw

Self tapping

screw

Machine

screws

Remove the spark plug.

Remove three self tapping screws and two machine screws from

the engine cover, and then gently move the engine cover aside.

Remove the three spark arrestor retaining screws, and then remove

the spark arrestor cover, screen, gasket, and chamber

Use a plastic scraper or wire brush to remove carbon deposits from

the arrestor screen, chamber, and cover.

Inspect the screen carefully, and replace any screen that has been

perforated, distorted, or is otherwise unserviceable.

Install the chamber, screen, gasket and cover in the reverse order

of disassembly, and then install and securely tighten the three cover

retaining screws.

Install the engine cover, and verify that the fuel line connections are

still tightly in place.

Install the engine cover retaining screws in the reverse order of

removal, and tighten securely.

Install and tighten the spark plug, and reconnect the spark plug

wire.

Drain the fuel if it is to be stored for an extended time.

Important!

Always replace cover screws in the same holes

from which they were removed. Substitution or

incorrect assembly of the engine cover screws

can permanently damage aluminium castings and

plastic components!

Storage for over 30 days

CLEANING Thoroughly clean the machine exterior.

INSPECTION Inspect the entire machine and tubes for damage,

including loose or missing components, and repair as necessary.

FUEL Drain the fuel tank, and then clear the carburettor and lines

by running the machine until it stops from lack of fuel.

LUBRICATION Remove the spark plug, and then pour

approximately 1/4-oz of oil into the cylinder through the spark plug

hole. Before reinstalling the spark plug, pull the recoil starter 2 or 3

times to distribute the oil over the cylinder walls.

AIR CLEANER Remove, clean, and reinstall the filter element as

described under “daily maintenance.”

STORAGE Store the machine in a clean, dry, dust free environment.

Warning!

Never store the machine with any fuel remaining in

the tank, fuel lines, or carburettor! Your warranty

does not include coverage for damage caused by

‘stale’ or contaminated fuels!

Loading ...

Loading ...

Loading ...