Loading ...

Loading ...

Loading ...

ENGLISH

8

select the best speed for a particular application. The more

you squeeze the trigger, the faster the tool will operate. For

maximum tool life, use variable speed only for starting holes

orfasteners.

NOTE: Continuous use in variable speed range is not

recommended. It may damage the switch and should

beavoided.

Forward/Reverse Control Button (Fig. A)

A forward/reverse control button

2

determines the

direction of the tool and also serves as a lock-offbutton.

To select forward rotation, release the trigger switch and

depress the forward/reverse control button on the right side

of thetool.

To select reverse, release the trigger switch and depress the

forward/reverse control button on the left side of thetool.

The center position of the control button locks the tool in

the off position. When changing the position of the control

button, be sure the trigger isreleased.

NOTE: The first time the tool is run after changing the

direction of rotation, you may hear a click on start up. This is

normal and does not indicate aproblem.

Worklight (Fig. A)

There is a worklight

7

located on the foot of the tool. The

worklight is activated when the trigger switch is depressed,

and will automatically turn off 20 seconds after the trigger

switch is released. If the trigger switch remains depressed,

the worklight will remain on. The light's timeout can be

adjusted or the light disabled in ToolConnect™.

NOTE: The worklight is for lighting the immediate work

surface and is not intended to be used as aflashlight.

ASSEMBLY AND ADJUSTMENTS

WARNING: To reduce the risk of serious personal

injury, turn unit off and remove the battery pack

before making any adjustments or removing/

installing attachments or accessories. An

accidental start-up can causeinjury.

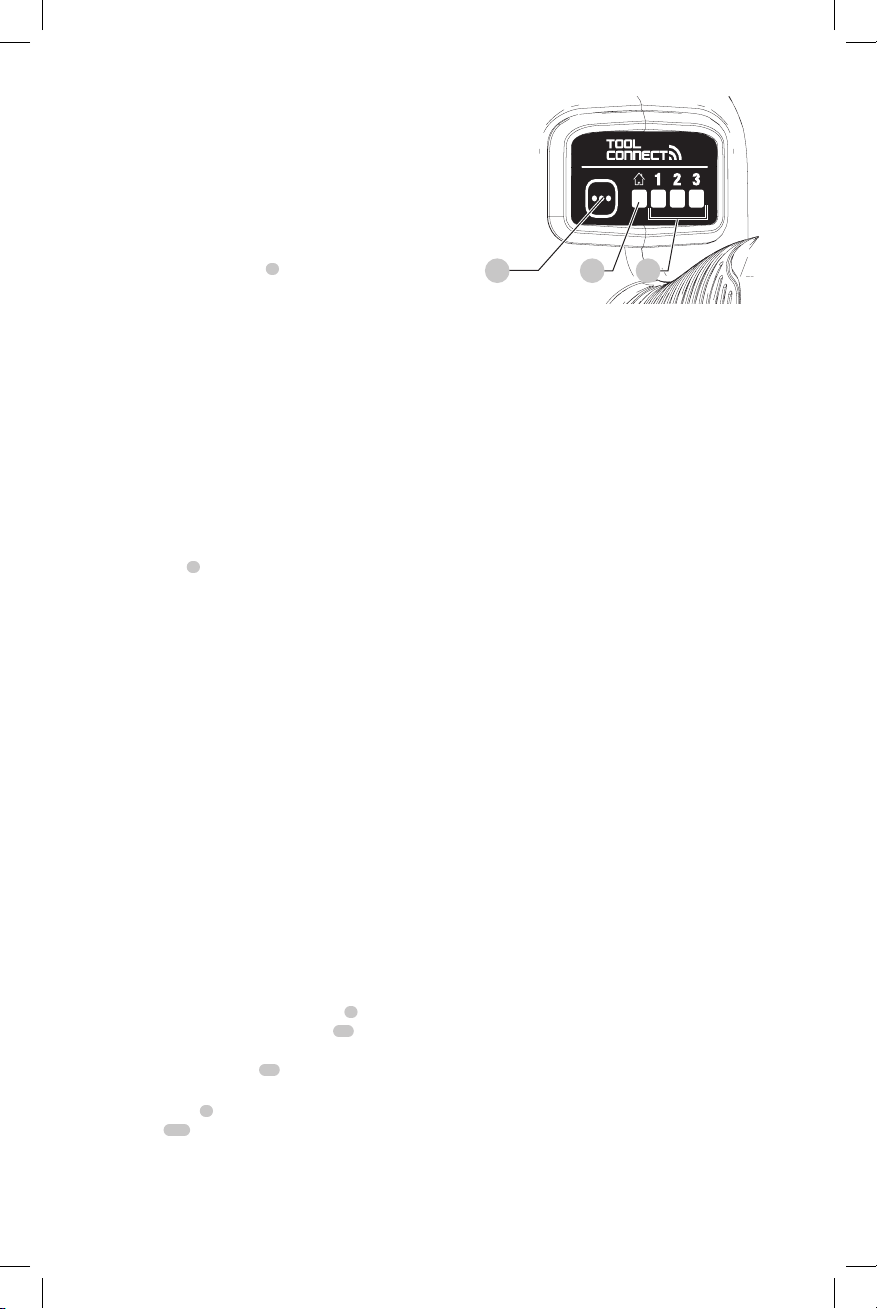

Tool Connect™ Mode Selector (Fig. D)

WARNING: To reduce the risk of injury, remove

accessories from the tool chuck before using the

modeselector.

The DCF896 and DCF896H are equipped with a mode

selector that allows Modes 1, 2, and 3 to be customized

using the Tool Connect™ app (refer to Table 1). Once

configured, pressing the mode selector button

8

on the

foot of the tool will cycle through the modes

13

. The Home

Mode settings are not customizable and the Home Mode is

active when the home indicator

12

is lit.

If you are unsure of the current configuration, press the

mode selector button

8

to set the tool to the Home Mode

(home indicator

12

is lit).

8

Fig. D

12 13

Precision Wrench™ (Fig. D)

In addition to normal impacting modes, this tool features

the Precision Wrench™ mode which grants the user greater

control in both fastening and loosening applications.

When set in forward, the tool will fasten at 2000 RPM until

impact begins. The tool will pause for a duration set by

the user in Tool Connect™ before continuing to impact

at a rate of 3100IPM, providing the user with greater

control and reducing the chance of overtightening or

damagingmaterial.

When set in reverse, the tool will impact at a normal speed

and rate of 3100 IPM. Upon sensing that the fastener has

broken free, the tool will cease to impact and will reduce

speed to help prevent “run-off” of loose hardware. Speed

reduction can be set by the user in ToolConnect™.

Impact Time

Tool will automatically shut off after impacting for a specific

time limit set by the user in the Tool Connect™app.

Precision Tap™

CAUTION: Use only impact-rated taps

andaccessories.

CAUTION: Tapping not recommended for use on

critical or precisionworkpieces.

CAUTION: Tap life is heavily affected by tool

alignment with the workpiece, speed settings,

material condition andlubrication.

CAUTION: Tap breakage may occur if tap is driven

too far without clearing chips. Choose tapping speed

and time settings that do not overload the tap by

driving it too far beforereversing.

CAUTION: Use caution not to drive a tap past the end

of its threads, or to bottom a tap in a blindhole.

CAUTION: Always follow tap manufacturer’s

guidelines for proper tap selection and use with

different materials, cutting fluids, tap drill sizes and

feedrates.

CAUTION: Precision Tap™ mode is not recommended

for use with taps less than 5/16" (8mm) or more than

3/4" (20 mm) indiameter.

CAUTION: Recommended tapping speeds in Tables

2 and 3 are a suggestion only, based on test results

tapping new threads at 75% thread depth. It is

recommended to perform a test application on scrap

material, starting at speed 1 and working up. Tapping

Loading ...

Loading ...

Loading ...