Loading ...

Loading ...

Loading ...

English

7

Fitting Guard

CAUTION: Do not operate grinder with a loose guard

or the guard latch in the openposition.

1. Place the angle grinder on a table, spindleup.

2. Press the guarddown.

3. Position the guard between your body and the

workpiece.

4. Tighten the screw holding the cinch collar firmly around

the neck of thespindle.

Fig. D

Removing Guard

1. Loosen the screw holding the cinch collar around the

neck of thespindle.

2. Lift up on theguard.

CAUTION: Do not tighten adjusting screw with guard

latch in open position. Undetectable damage to the

guard or the mounting hub mayresult.

CAUTION: Edge grinding can be performed with

Type 27 wheels designed and specified for this

purpose; 1/4" (6.35 mm) thick wheels are designed for

surface grinding while thinner Type 27 wheels need

to be examined for the manufacturer's label to see

if they can be used for surface grinding or only edge

grinding/cutting. Wheels where surface grinding is not

permitted cannot be used with thisgrinder.

Flanges and Wheels

CAUTION: Turn unit off and unplug the tool before

making any adjustments or removing or installing

attachments oraccessories.

Mounting Non-Hubbed Wheels (Fig. E, F)

WARNING: Failure to properly seat the flanges and/or

wheel could result in serious injury (or damage to the

tool orwheel).

CAUTION: Included flanges must be used with

depressed center Type 27/42 grinding wheels and

Type1/41 cutting wheels. See the Accessories Chart

for moreinformation.

WARNING: A closed, two-sided cutting wheel guard

is required when using abrasive cutting wheels or

diamond coated cutting wheels.

WARNING: Use of a damaged flange or guard or fail-

ure to use proper flange and guard can re sult in injury

due to wheel breakage and wheel contact. See the

Accessories Chart for moreinformation.

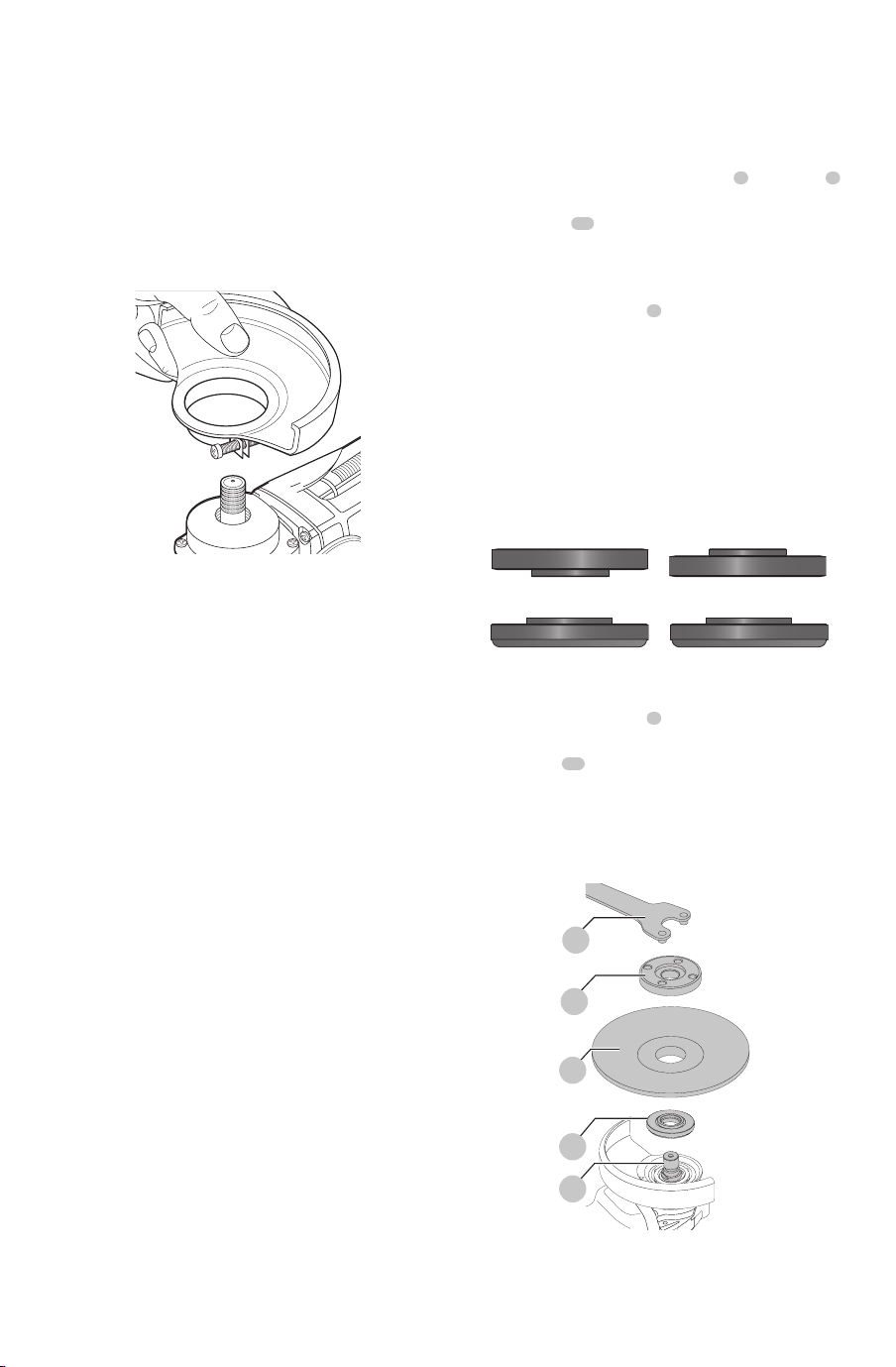

1. Place the tool on a table, guardup.

2. Install the unthreaded backing flange

3

, on spindle

1

with the raised center (pilot) facing the wheel.

3. Place wheel

13

against the backing flange,

centering the wheel on the raised center (pilot) of the

backingflange.

4. While depressing the spindle lock button thread the

threaded locking flange

4

on spindle.

nOTE: If the wheel you are installing is more than 1/8"

(3.17mm) thick, place the threaded locking flange on

the spindle so that the raised section (pilot) fits into the

center of the wheel. If the wheel you are installing is

1/8" (3.17mm) thick or less, place the threaded locking

flange on the spindle so that the raised section (pilot) is

not against thewheel.

Fig. E

Over 1/8" (3.17mm)

wheels

Backing Flange

Locking flange

1/8" Or less (3.17mm)

wheels

Backing Flange

Locking flange

5. While depressing the spindle lock button, tighten the

threaded locking flange

4

:

a. Tighten the threaded locking flange using a

wrench

14

.

b. Tighten a keyless locking flange by hand. (Only use a

keyless locking flange if it is in perfect condition.)

6. To remove the wheel, depress the spindle lock button

and loosen the threaded lockingflange.

Fig. F

1

3

13

4

14

Loading ...

Loading ...

Loading ...