Loading ...

Loading ...

Loading ...

5

the exact type of material to be used. The installation of

unions on the inlet and outlet water lines and a shut-off

valve in at least the cold water line is recommended so

the water heater may be easily disconnected for servic-

ing. Dielectric unions are not required for protection of

the water heater.

When this water heater is supplying general purpose hot

water requirements for use by individuals, a thermostati-

cally controlled mixing valve is recommended to reduce

the risk of scald injury. Contact a licensed plumber or

the local plumbing authority for further information.

Thermometer(s) should be installed so that they indicate

the temperature of the water at or near the outlet of the

water heater and storage tank(s) if provided. See Fig. 2

or 3.

4. RELIEF VALVE — A new combination pressure and

temperature relief valve, complying with the Standard

for Relief Valves and Automatic Gas Shutoff Devices

for Hot Water Supply Systems, ANSI Z21.22, is factory

installed on this water heater at the time of manufacture.

No valve is to be placed between the relief valve and the

water heater. For a circulating tank installation, the sepa-

rate storage tank(s) must have similar protection. Local

codes shall govern the installation of relief valves.

The pressure rating of the relief valve must not exceed

150 psi (1034kPa)(160 psi (1103kPa) for ASME models)),

the maximum working pressure of the water heater as

marked on the rating plate. The Btu/h rating of the relief

valve must not be less than the input rating of the water

heater as indicated on the rating plate located on the

front of the heater. (1 watt = 3.412 Btu/h).

Connect the outlet of the relief valve to a suitable open

drain so that the discharge water cannot contact live

electrical parts. The discharge line must pitch downward

from the valve to allow complete draining (by gravity) of

the relief valve and discharge line and be no smaller than

the outlet of the valve. The end of the discharge line

should not be threaded or

concealed and should be protected from freezing. No

valve of any type, restriction or reducer coupling should

be installed in the discharge line. Local codes shall govern

the installation of relief valves.

5. TO FILL WATER HEATER — Make certain drain valve is

completely closed. Open shut-off valve in cold water sup-

ply line. Open each hot water faucet slowly to allow air to

vent from the water heater and piping. A steady flow of

water from the hot water faucet(s) indicates a full water

heater.

Installation

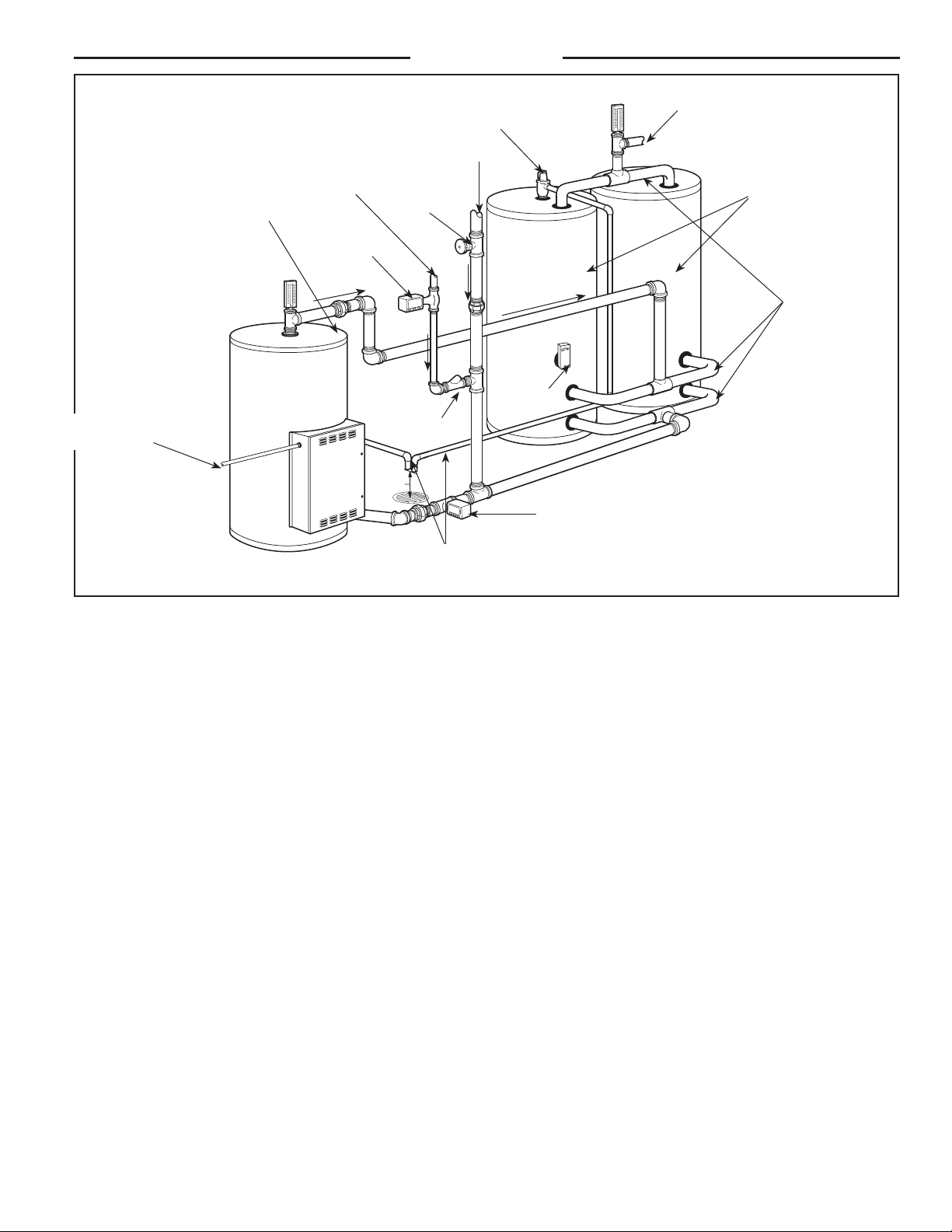

Figure 3. — Typical Forced Circulation Tank System with factory supplied jacketed and insulated storage tanks.

Temperature & Pressure Relief Valve

(Not visible in this view)

Refer to Local Codes

Storage Tank Temperature & Pressure Relief Valve

Refer to Local Codes

Temperature & Pressure Relief Valve(s)

Discharge Pipe(s) to suitable open drain

Branch Circuit from

Electrical Distribution Panel

Circulator*

* Circulator may be wired to run con-

tinuously without the control

Circulator

Control

(Optional*)

Manifolds

Cold Water Inlet

Shut-off Valve

Air Gap

6” (152mm)

Check Valve

Recirculation Loop

Recirculator

Storage Tanks

Hot Outlet

Vacuum Relief Valve

(Not visible in this view)

If required by local codes

Loading ...

Loading ...

Loading ...