Loading ...

Loading ...

Loading ...

Unit Side

(Field-Supplied)

Insulating Pipe

(Field-Supplied)

Cord Clamp

(Factory-Supplied)

Insulating Pipe

(Field-Supplied)

Refrigeration Piping

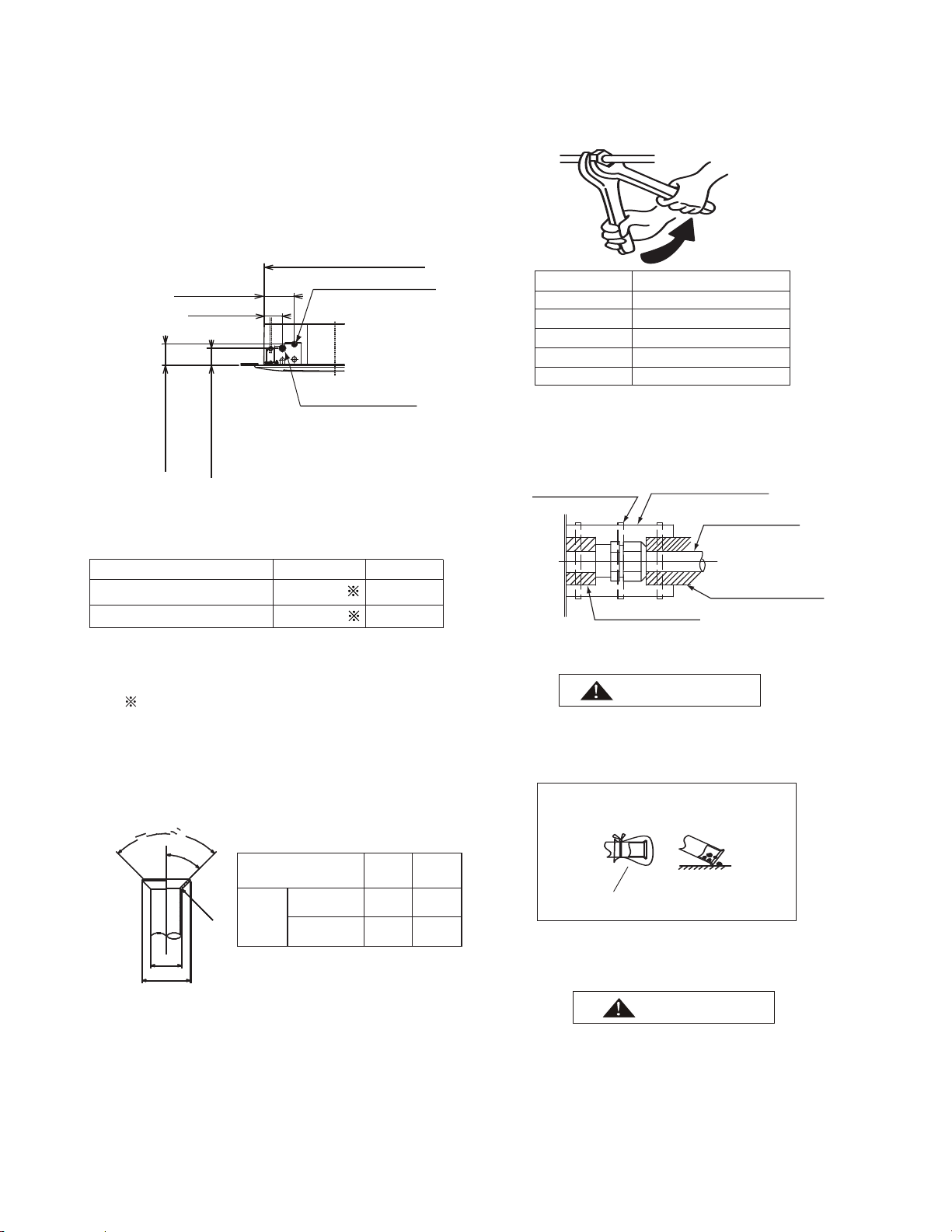

Fig. 5.1 Pipe Connection Points

Fig. 5.2 Pipe Diameter

Since the nut cap connected at gas pipe is

designed exclusively for R410A, the piping flaring

connected for off-factory installation is adjusted as

compared with R22 and R407C. Please perform

the processing operation based on the dimensions

shown below: (See Fig. 5.3)

(2) As shown in Fig. 5.4, two spanners shall be used for

Insulating Pipe

Cap the end of the pipe when the pipe is to

penetrate a hole.

Do not put pipes on the ground directly without a

cap or vinyl tape arranged at the end of the pipe.

Do not put pipes on the ground directly

Correct

Incorrect

Blocked with Tape or Plug

(4) Discharging and Charging Refrigerant

Follow the Installation & Maintenance Manual for

outdoor unit.

Excessive and inadequate refrigerant is a leading

cause of system anomaly.

Please inject the right amount of refrigerant.

Pipe Size.(mm)

TighteningTorque ft·(N.m)

10.3~13.3(14~)

29.5(40)

44.3(60)

48.7~56.8(63~77)

Outside Diameter of

Piping (a)

Outside

Diameter

of Flaring

(D)

R410A

21/32

(16.6)

25/32

(19.7)

Unit: in. (mm)

1/2

5/8

(Φ12.7)

(Φ15.88)

Fig. 5.3 Flaring

5.2 Piping Connection

Fig. 5.4 Nut tightening torque

(3) Insulate the refrigeration piping with field-

supplied insulating pipe upon completion of

refrigerant pipe connection. See Fig. 5.5.

Fig. 5.5 Insulation on Pipes

90

0

±2

0

45

0

R0.4~0.8

a

D

0

-0.4

±2

0

●

●

(1) The connection point and diameter of piping

are shown in Figs. 5.1 and 5.2.

Unit: in.(mm)

73.8(100)

5

Gas Pipe

Liquid Pipe

Capacity of indoor unit(kBtu/h)

1/2(Φ12.7)

5/8(Φ15.88)

1/4(Φ6.35)

3/8(Φ9.53)

09~22

24~54

R22、R407C

41/64

(16.2)

49/64

(19.4)

5-29/32(150) (Connected to

Gas Pipe)

6-37/64(167) (Connected to

Liquid Pipe)

33-5/64(0) ( )

6-19/64(160) (Liquid Pipe)

3-47/64(9) (Gas Pipe)

5/8(Φ15.88)

1/2(Φ12.7)

3/8(Φ9.53)

1/4(Φ6.35)

3/4(Φ19.05)

Unit: in.(mm)

Loading ...

Loading ...

Loading ...