Loading ...

Loading ...

Loading ...

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

COMPONENTS (FIG. 1)

A. Trigger

B. Exhaust

C. Rafter hook

D. Contact trip

E. Pusher

F. Magazine

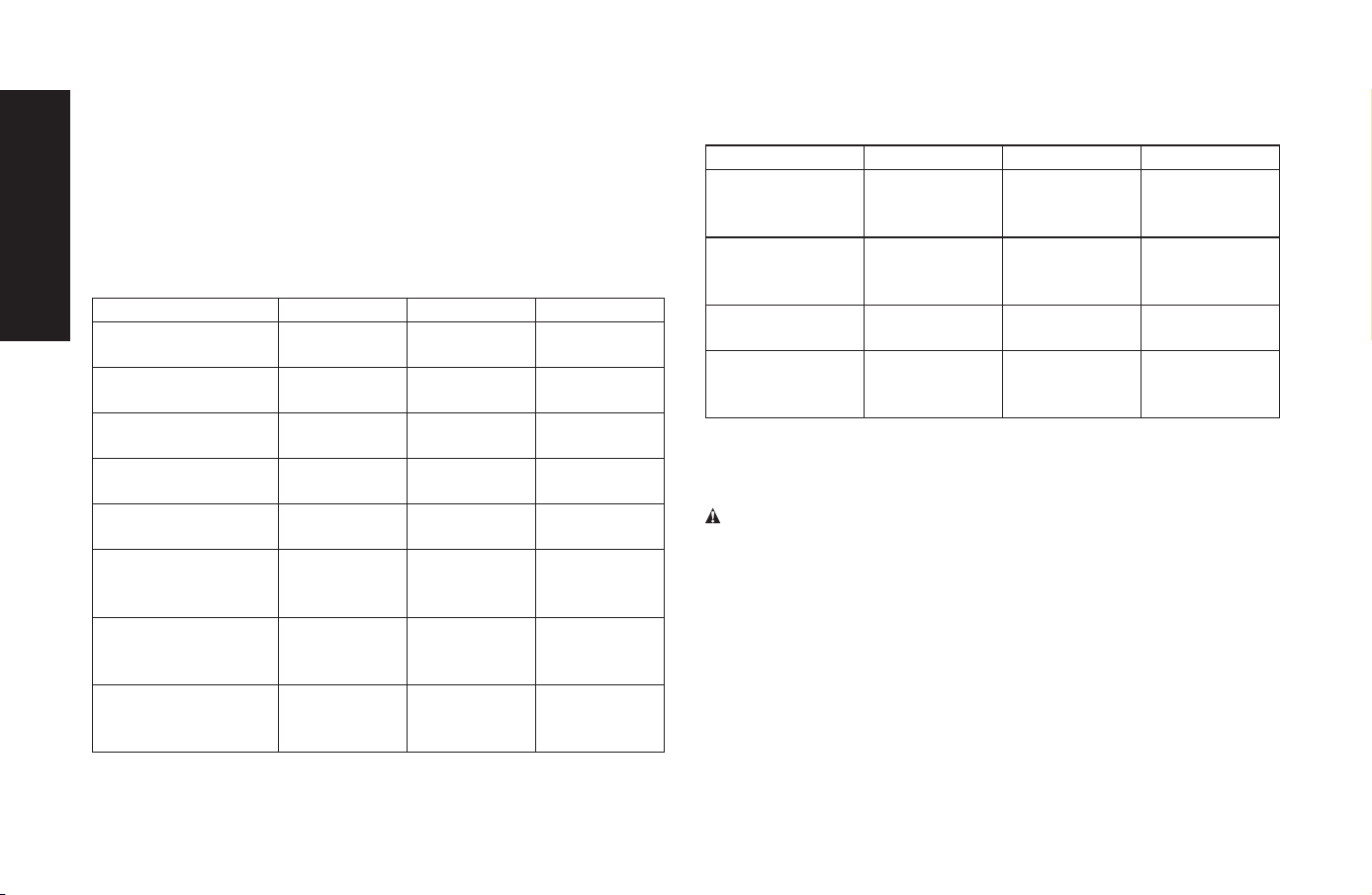

Tool Specifications

MODEL DWF83PL DWF83PT DWF83WW

HEIGHT 12.5"

(317.5 mm)

12.75"

(323.85 mm)

12.75

(323.85 mm)

WIDTH 4.95"

(125.7 mm)

4.95"

(125.7 mm)

4.95

(125.7 mm)

LENGTH 21.5"

(546.1 mm)

19.7" (500

mm)

20.5

(520.7mm)

WEIGHT 8.0 lb

(3.63 kg)

8.1 lb

(3.67 kg)

8.2

(3.72 kg)

NOSE TO WALL

DISTANCE

2.5"

(64 mm)

2.5"

(64 mm)

2.5"

(64 mm)

RECOMMENDED

OPERATING

PRESSURE

70 - 120 psig 70 - 120 psig 70 - 120 psig

AIR

CONSUMPTION

PER 100 CYCLES

6.1 cfm

@ 80 psi

6.1 cfm

@ 80 psi

6.1 cfm

@ 80 psi

LOADING

CAPACITY

2 sticks (25

nails/stick) of

12D148 ring

2 sticks (37

nails/stick) of

12D131 ring

4 sticks (25

nails/stick) of

12D131 ring

Nail Specifications

NOTE: Use only D

EWALT approved fasteners.

MODEL DWF83PL DWF83PT DWF83WW

NAIL LENGTHS 2" - 3-1/4"

(50 mm -

83 mm)

2" - 3-1/4"

(50 mm -

83 mm)

2" - 3-1/4"

(50 mm -

83 mm)

SHANK

DIAMETERS

.113" - .148"

(2.8 mm -

3.7 mm)

.113" - .131"

(2.8 mm -

3.3 mm)

.113" - .131"

(2.8 mm -

3.3 mm)

FASTENER

COLLATION

21° Plastic

collated

30° - 34°

Paper tape

28° wire

collated

NAIL TYPE 21° round

head

30° clipped

head/ 30° full

head

28° notched

head/28° full

head

OPERATION

Preparing the Tool (Fig. 2, 3)

WARNING: Read the section titled Important Safety Instructions

at the beginning of this manual. Always wear eye and ear protection

when operating this tool. Keep the nailer pointed away from yourself

and others. For safe operation, complete the following procedures

and checks before each use of the nailer.

1. Before you use the nailer, be sure that the compressor tanks

have been properly drained.

2. Lubricate the tool following these directions:

a. Use D

EWALT pneumatic tool oil or a non-detergent S.A.E. 20

weight oil. DO NOT use detergent oil or additives as they will

damage o-rings and rubber parts.

b. Use a filter-regulator-lubricator in the air line between the

compressor and the tool when possible.

English

6

Loading ...

Loading ...

Loading ...