Loading ...

Loading ...

Loading ...

9

MACHINE USE

MATERIAL HOLD-DOWN

AIR HOSE

SPEED CONTROL KNOB

FRETWORK

SAWING

BEVELING

The material hold-down (F) Fig. 7 should contact the

surface of the workpiece. To adjust the material hold-

down, loosen the thumbscrew (D) Fig. 7 and move the

rod up or down.

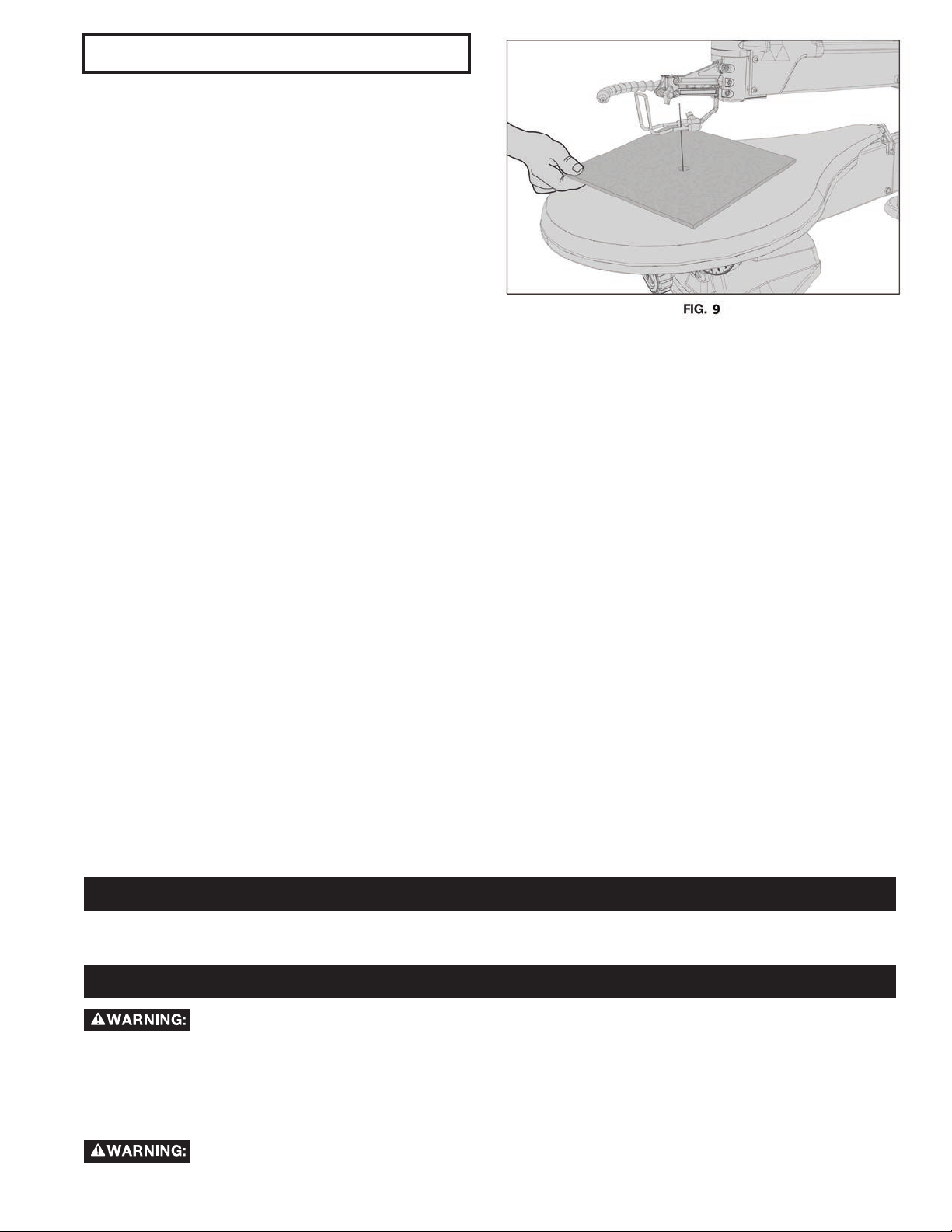

The material hold-down must be beveled when the table

is beveled. To bevel the material hold-down, loosen the

hex screw (E) Fig. 9 and bevel the material hold-down

until it is parallel to the table. Retighten the material

hold-down before cutting.

NOTE: When cutting, ensure the material hold-down

does not contact the bottom arm of the scroll saw. Your

scroll saw has a maximum thickness capacity of 2” (50.8

mm). Do not cut material thicker than 2” (50.8 mm).

NEVER remove the material hold-down since it also

functions as a barrier between ngers and blade.

the bevel lock knob (H) Fig. 8, and bevel the table to the

desired setting on the bevel scale (J), indicated by the

bevel pointer (I).

NOTE: Before tilting the table for bevel cuts of 45°,

check the clearance around the lower thumbscrew. To

faciliate an accurate 45° cut, the thumbscrew and set

screw may need to change places. On the setscrew

side, sufficient clearance is available.

Your scroll saw features an adjustable air (G) Fig. 7 hose

to keep your work area free from dust and debris. Be

sure to position the air hose properly: it should blow saw

dust away from the operator.

Your scroll saw features a variable speed control, from

400 to 1,750 strokes per minute. To operate the variable

speed feature, turn the speed control knob (C) Fig. 6

with the saw running.

To increase the speed, turn the knob clockwise. The

numbers on the control knob represent speed ranges.

One is the minimum speed, 8 is the maximum speed.

Slower speeds are recommended for metals, plastics,

harder woods and very thin materials.

INSIDE CUTS

Your scroll saw is ideal for making inside cuts for detail

work. To make an inside cut:

1. Drill a pilot hole in your workpiece.

2. Make sure the blade tension lever is moved fully to

the right.

3. Loosen the top thumbscrew blade clamp.

4. Leaving the blade held in place by the bottom blade

clamp, lift the top arm of the scroll saw, as shown

in Figure 9. Thread the saw blade through the pilot

hole in your workpiece and reattach the blade by

tightening the top thumbscrew.

5. Readjust the blade tension and begin the inside cut.

Alternately, you can loosen the bottom thumbscrew

blade clamp in step 3 above, and thread the blade

through the top of the workpiece.

NOTE: Do not lift saw by upper arm. Damage will occur.

Hold material rmly against table. Always feed material

toward the blade. Feed the workpiece enough to allow

the blade to cut, but do not force material into blade too

quickly.

The table of your scroll saw bevels 45° left and right. A

detent is set at 0°. To bevel the scroll saw table, loosen

For assistance with your machine, visit our website at www.DeltaMachinery.com for a list of service centers or call the

DELTA® Power Equipment Corporation help line at 1-800-223-7278.

To reduce the risk of injury, turn unit off and disconnect it from power source before installing and

removing accessories, before adjusting or when making repairs. An accidental start-up can cause

injury.

KEEP MACHINE CLEAN

Periodically blow out all air passages with dry compressed air. All plastic parts should be cleaned with a soft damp

cloth. NEVER use solvents to clean plastic parts. They could possibly dissolve or otherwise damage the material.

Wear certied safety equipment for eye, hearing and respiratory protection while using compressed air.

TROUBLESHOOTING

MAINTENANCE

Loading ...

Loading ...

Loading ...