Loading ...

Loading ...

Loading ...

- 5 -

OPERATION INSTRUCTIONS

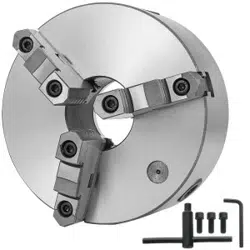

The jaws of the series chucks have two types:

①Model k11 is of solid jaw. One chuck has a set of internal and external

jaws which can be used separately.

② Model K11A(or K11C) is of two-piece jaw, which is composed of Base

jaw and reversible top jaw. The two-piece jaws can perform. As internal or

external jaws through adjustment. According to chucking diameters, soft

top jaws can bere-machined so as to achieve ideal clamping accuracy. The

connection dimensions for two-picce jaws of model K11A conform to

GB4346 (IS03442) Standards.

Caution

a)Don't add a tube on the wrench when clamping the workpiece to avoid

the input torque exceeding the limit will break the chuck.

b)Don't clamp the workpiece in the max clamping range if possible.

c)Don't run at the max speed when approaching the max clamping limit.

d)The chucks with "0"gear in clamping at last to ensure accuracy.

e)Don't exceed chuck max speed during operation.

Maintenance and inspection

1 Chucks should be maintained while the machine tools maintain.

2 Lubricate (at the grease cup)and clean(use the compressed air) the

chucks every day, in order to maintain its accuracy and durability.

3 Wash and lubricate all the working surfaces of the chucks at least two

times every year.When the using frequency of the machine tool grow or at

the special operation conditions,add the maintenance times of the chucks.

Troubleshooting

Troubleshooting and measurement see Table.5.

Loading ...

Loading ...

Loading ...