Loading ...

Loading ...

Loading ...

5.1 Piping Materials

(1) Prepare field-supplied copper pipes.

(2) Select clean copper pipes. Make sure there is no dust and

moisture inside. Blow the inside of the pipes with nitrogen or dry

air, to remove any dust or foreign materials before connecting

pipes.

(3) Select copper pipes based on Fig. 5.2.

9

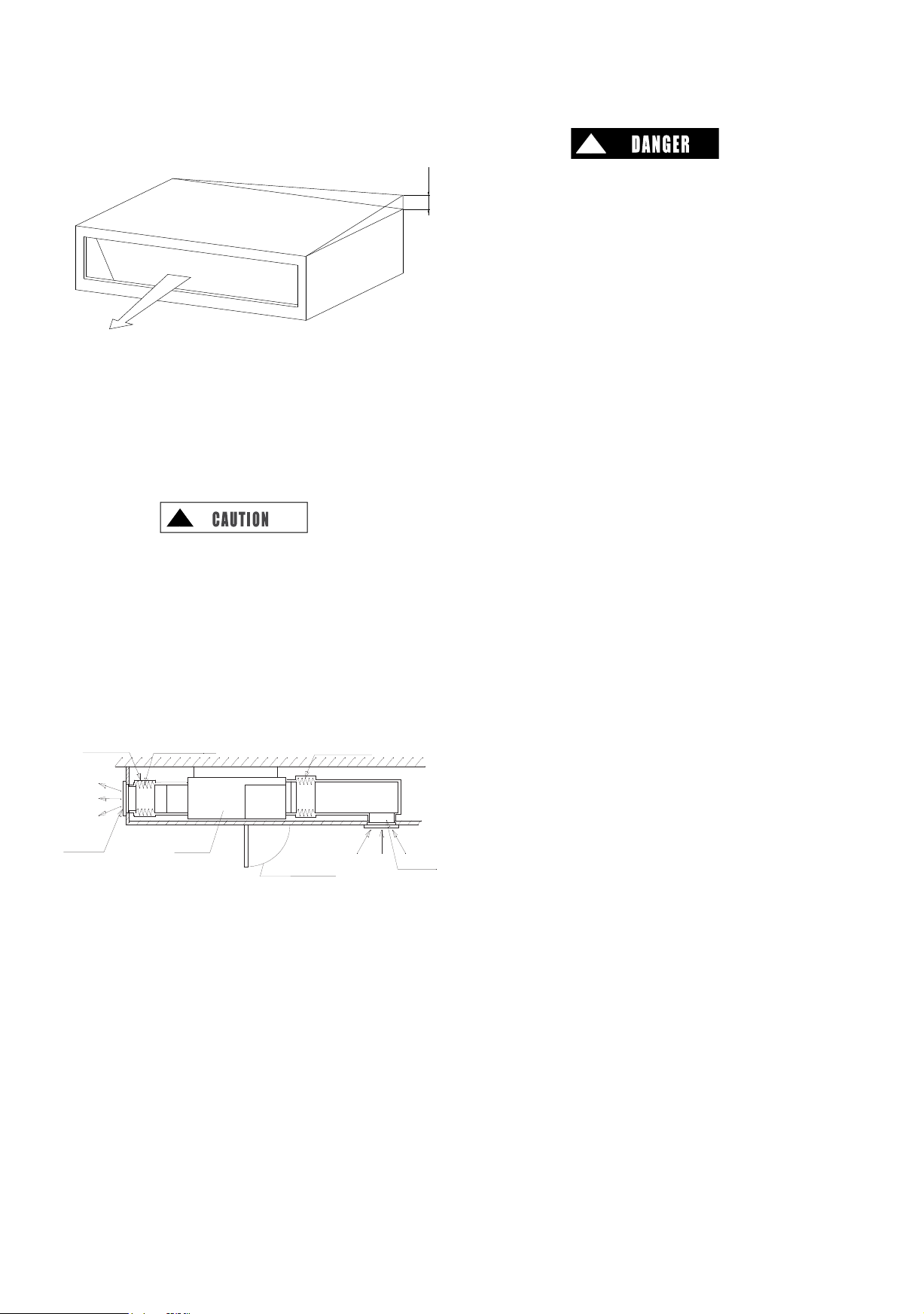

Flexible Canvas Connection

Thermal

Insulation Material

Flexible Canvas Connection

Return Air Inlet

Air Outlet

Level

Fig. 4.8 Top Surface Inclination Degree

Service Access

(with Filter Screen)

Fig. 4.9 Air Duct Connection

4.4.4 Leveling of Indoor Unit

(1) Check to ensure the top surface is level, and

measure the max. top surface inclination degree.

(2) As shown in Fig. 4.8, the rear part of indoor unit is slightly

lower than its front part (by 0~13/64 in.) so as to facilitate

drainage.

(3) Tighten the suspension nut upon completion of

adjustment. It's essential to apply thread locking agent to

avoid nut looseness.

!

Please cover the machine with plastic cloth during installation

so as to keep it clean.

4.4.5 Air Duct Connection

Air duct is connected to indoor unit via canvas hose to

effectively isolate noise and vibration.

<Example>

5.

Refrigerant Piping Work

!

Use refrigerant R410A in the refrigerant cycle. Do not charge

oxygen, acetylene or other flammable and poisonous gases into

the refrigerant cycle when performing a leakage test or an air-

tight test. These types of gases are extremely dangerous and

can cause an explosion. It is recommended that nitrogen be

used for these tests.

13/16 inch

(23-5/8 in.×23-5/8 in.)

Loading ...

Loading ...

Loading ...