Loading ...

Loading ...

Loading ...

4

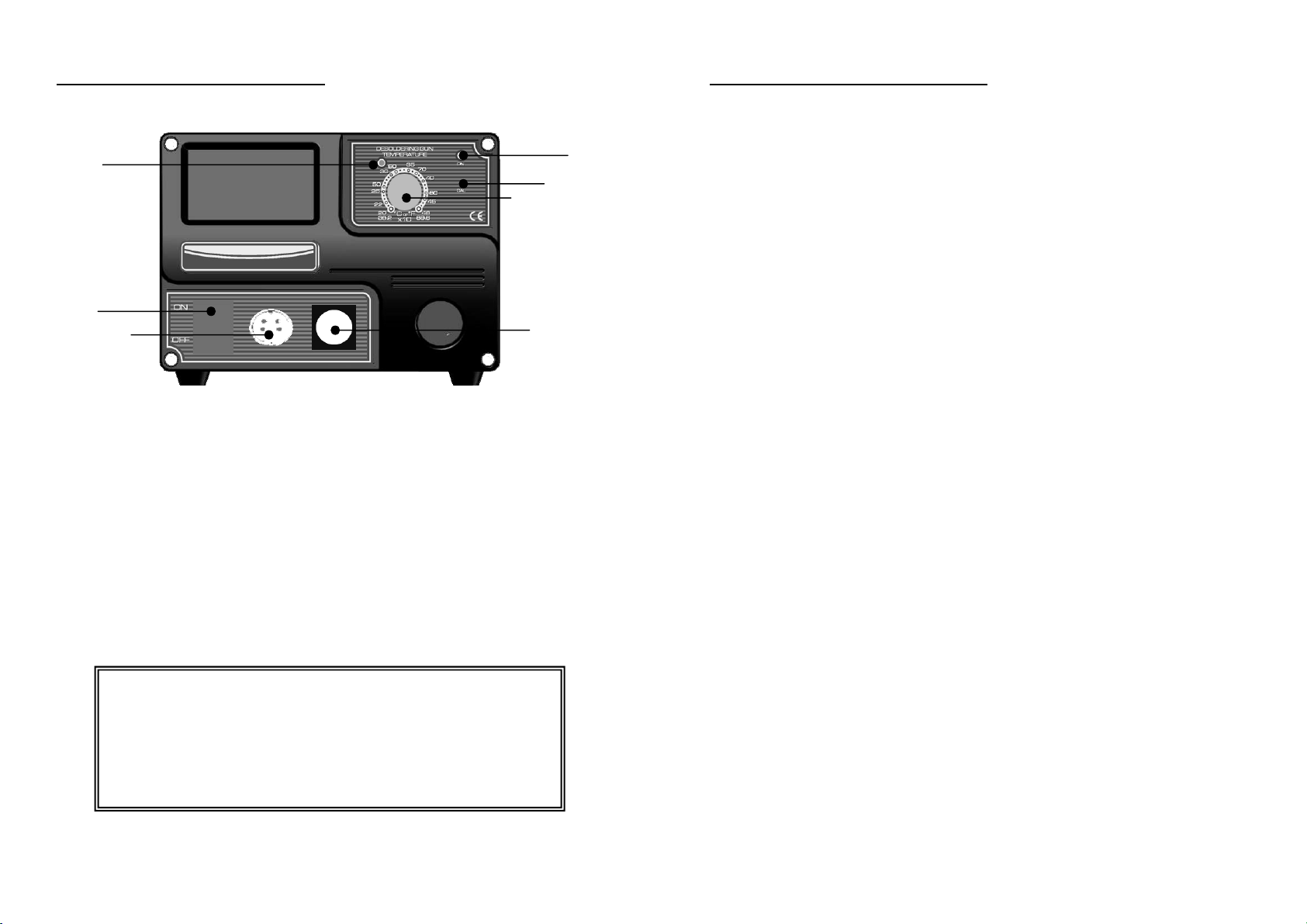

CONTROL PANEL GUIDE

LEGEND:

1 Desoldering gun heater lamp

2 Power indicator

3 Calibrator

4 Desoldering gun temperature adjust knob

5 Power switch

6 Desoldering gun receptacle

7 Suction receptacle

6

1

2

4

3

5

7

IMPORTANT:

REMOVE THE SCREW located at the center of the bottom

part of the main unit. This screw holds the pump in place during

transportation. Failing to remove the screw before using the

equipment can cause damage to the system.

5

OPERATING GUIDELINES

Please refer to the CONTROL PANEL GUIDE page for panel reference.

1. Make sure unit is unplugged and power switched off.

2. Connect the cord assembly of the desoldering gun to its receptacle.

3. Connect the vacuum suction tube to the suction receptacle.

4. Plug unit to AC supply.

5. Turn the Desoldering Gun ON . The Power indicator lamp would light

up.

6. The nozzle begins to heat up as soon as the switch is turned ON.

While heating up the heater lamp will continuously be lit. The lamp will

start to blink when the set temperature has been reached.

7. Adjust knob (“4” from the control panel) to the appropriate desolder-

ing temperature. Always set the temperature to the lowest possible

working temperature.

8. Wait a few minutes or until Nozzle is hot enough to melt solder.

9. Keep the nozzle clean. If the tip of the nozzle is coated with oxide, the

nozzle’s heat conductivity will be lowered.

10. Always place the desoldering gun in its holder when not in use.

11. Apply the nozzle to the solder until the solder melts.

12. Never allow the nozzle to touch the Board itself.

13. Confirm that the solder is melted, to confirm that all the solder is

melted, observe the inside of the hole and the backside of the

PCB. If this is difficult to do, try slowly moving the lead with the noz-

zle-if the lead moves, the solder is melted.

14. Never move the lead by force .lf it doesn’t move easily, the solder is

not fully melted.

15. After confirming that the solder is completely melted, absorb the solder by

squeezing the trigger.

16. Never leave any solder remaining inside the hole in the PCB.

17. After fully absorbing all the solder ,cool the soldering junction in order to pre-

vent it from becoming re-soldered.

18. If solder remains, re-solder the component and repeat the desoldering proc-

ess.