Loading ...

Loading ...

Loading ...

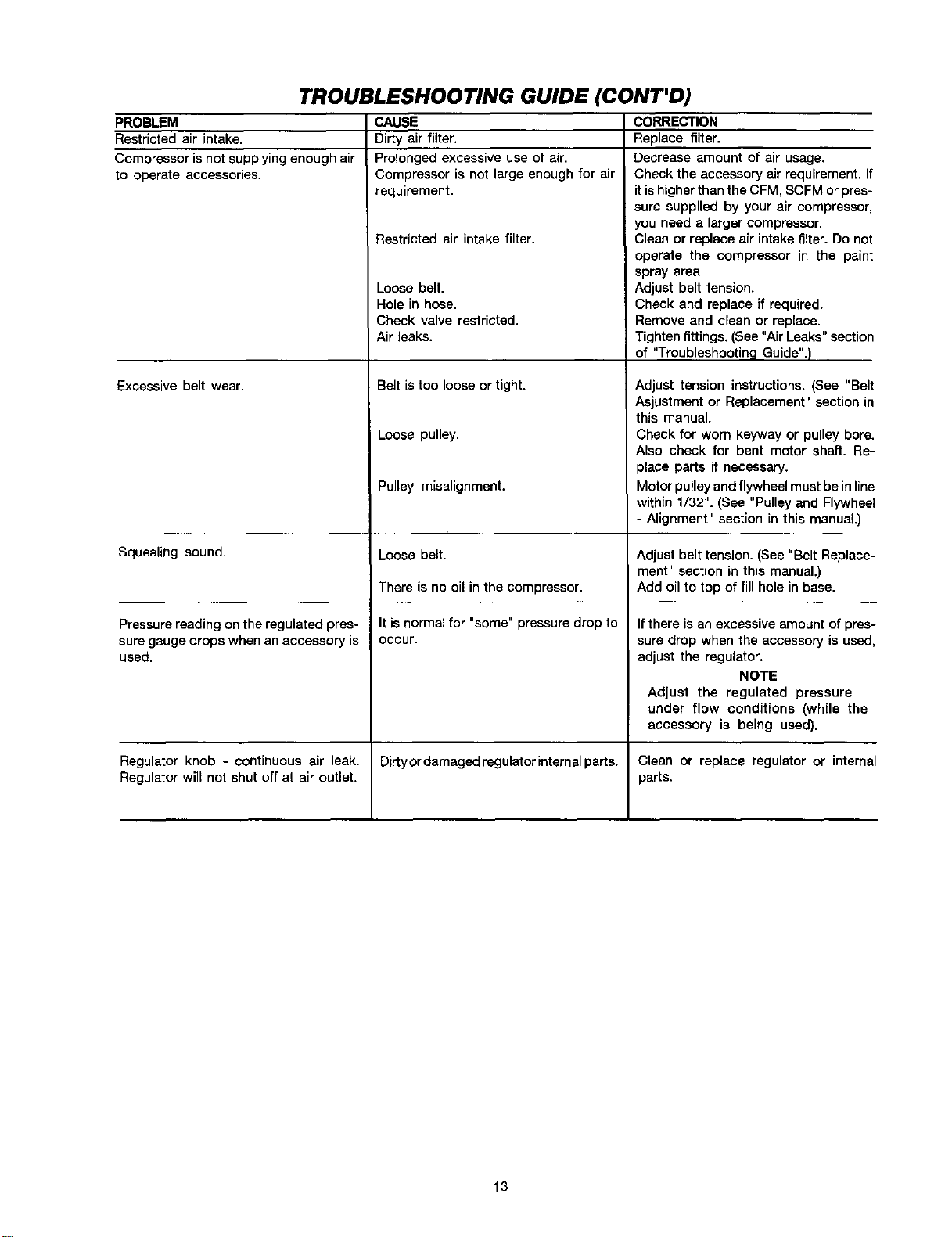

TROUBLESHOOTING GUIDE (CONT'D)

PROBLEM

Restricted air intake.

Compressor isnot supplying enough air

to operate accessories.

CAUSE

Dirty air filter,

Prolonged excessive use of air.

Compressor is not large enough for air

requirement.

Excessive belt wear,

Restricted air intake filter.

Loose belt.

Hole in hose.

Check valve restricted,

Air leaks.

Belt is too loose or tight.

Loose pulley.

Pulley misalignment.

Squealing sound. Loose belt.

There is no oil in the compressor.

It is normal for "some" pressure drop to

occur.

Pressure reading on the regulated pres-

sure gauge drops when an accessory is

used.

Dirty or damaged regulator internalparts.

Regulator knob - continuous air leak.

Regulator will not shut off at air outlet.

CORRECTION

Replace filter.

Decrease amount of air usage.

Check the accessory air requirement. If

itis higherthan theCFM, SCFM or pres-

sure supplied by your air compressor,

you need a larger compressor,

Clean or replace air intake filter. Do not

operate the compressor in the paint

spray area.

Adjust belt tension.

Check and replace if required.

Remove and clean or replace,

Tighten fittings. (See "Air Leaks"section

of "Troubleshooting Guide".)

Adjust tension instructions. (See "Belt

Asjustment or Replacement" section in

this manual.

Check for worn keyway or pulley bore.

Also check for bent motor shaft. Re-

)lace parts if necessary.

Motor pulleyand flywheel mustbe inline

within 1/32". (See "Pulley and Flywheel

- Alignment" section in this manual,)

Adjust belt tension. (See "Belt Replace-

ment" section in this manual.)

Add oil to top of fill hole in base.

If there is an excessive amount of pres-

sure drop when the accessory is used,

adjust the regulator.

NOTE

Adjust the regulated pressure

under flow conditions (while the

accessory is being used),

Clean or replace regulator or internal

_arts.

13

Loading ...

Loading ...

Loading ...