Loading ...

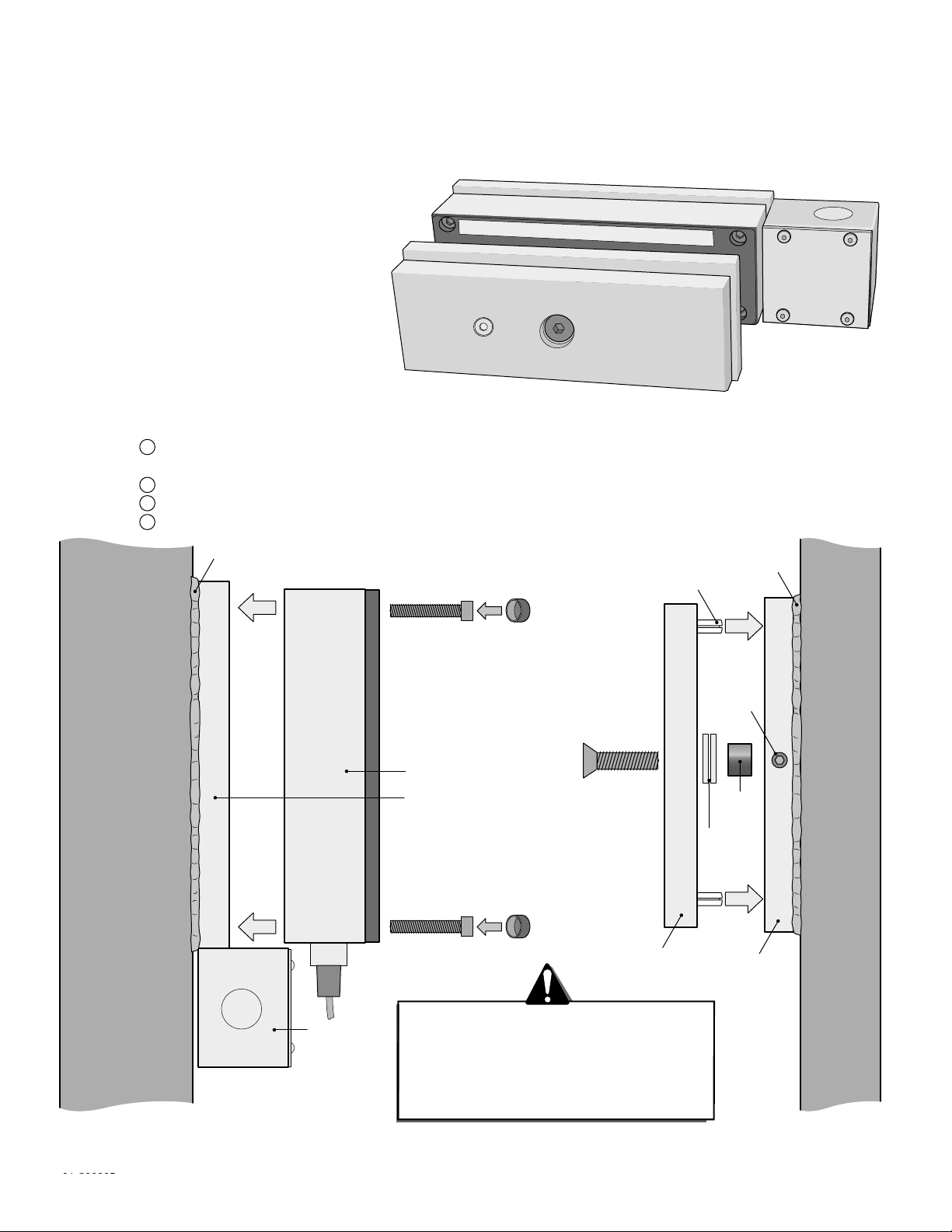

Junction Box

Magnetic Lock

Magnetic Lock

Mounting Screws

Anti-Tamper Plug

Armature

Screw

Rubber

Washer

Washers

Armature

Plate

Guide

Pins

Armature

POST

GATE

Welding

Welding

Armature

Allen Screw

Magnetic Lock Plate

Position the magnetic lock with armature plate at desired location and tack weld the magnetic lock plate to the gate post.

Do not fully weld or you will burn the wire or lock.

Tack weld armature plate to gate. Again,

Do not fully weld or you will burn the rubber pieces.

Remove the armature plate with rubber washer and magnetic lock from the junction box and

fully weld the plates.

After it cools-off, reassemble magnetic lock and armature with the rubber washer.

HANDLING:

The magnetic lock, junction box and

magnet plate are ruggedly constructed and designed to

provide years of trouble-free service. Care must be taken,

however, during installation and during actual use so that

the magnet face and magnet plate face are free of dirt,

rust, burrs, paint, or any other obstruction which may

interfere with the magnet and magnet plate making good

contact.

1

2

3

4

MOUNTING INSTALLATION

Anti-Tamper Plug

For Technical Support: www.liftmaster.com 1-800-528-2806

© 2011 The Chamberlain Group, Inc.

All Rights Reserved01-50688D

It is necessary to separate the MG 1300

parts from the armature and magnet

plates prior to welding.

Failure to do so will cause the wiring

and rubber pieces to burn and melt.

MOUNTING THE MG 1300 MAGNETIC LOCK

01-50688E