Loading ...

Loading ...

Loading ...

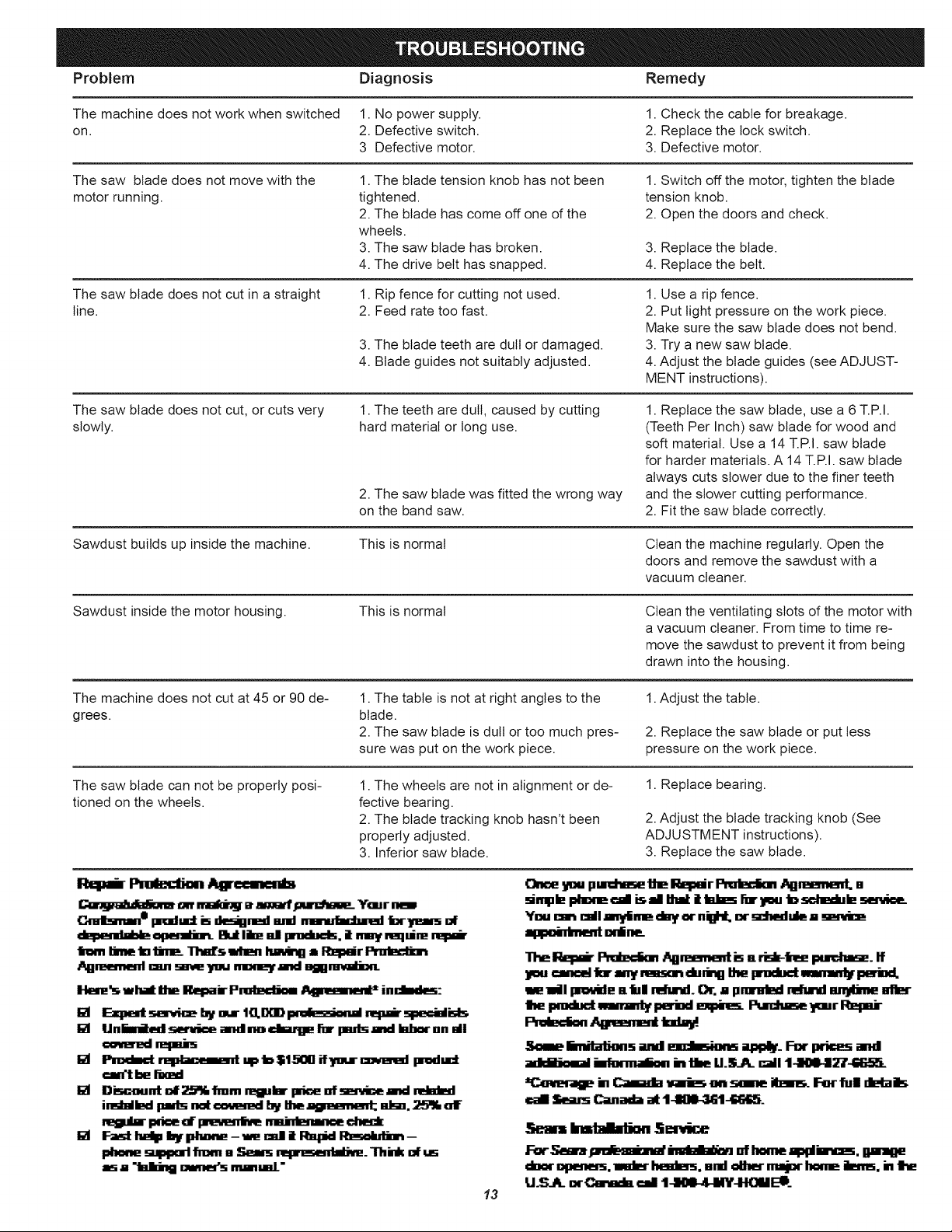

ProbJem Diagnosis Remedy

The machine does not work when switched 1. No power supply. 1. Check the cable for breakage.

on. 2. Defective switch. 2. Replace the lock switch.

3 Defective motor. 3. Defective motor.

The saw blade does not move with the

motor running.

The saw blade does not cut in a straight

line.

1. The blade tension knob has not been

tightened.

2. The blade has come off one d the

wheels.

3. The saw blade has broken.

4. The drive belt has snapped.

1. Rip fence for cutting not used.

2. Feed rate too fast.

3. The blade teeth are dull or damaged.

4. Blade guides not suitably adjusted.

1. Switch off the motor, tighten the blade

tension knob.

2. Open the doors and check.

3. Replace the blade.

4. Replace the belt.

1. Use a rip fence.

2. Put light pressure on the work piece.

Make sure the saw blade does not bend.

3. Try a new saw blade.

4. Adjust the blade guides (see ADJUST-

MENT instructions).

The saw blade does not cut, or cuts very

slowly.

1. The teeth are dull, caused by cutting

hard material or long use.

2. The saw blade was fitted the wrong way

on the band saw.

1. Replace the saw blade, use a 6 T.P.I.

(Teeth Per Inch) saw blade for wood and

soft material. Use a 14 T.P.I. saw blade

for harder materials. A 14 T.RI. saw blade

always cuts slower due to the finer teeth

and the slower cutting performance.

2. Fit the saw blade correctly.

Sawdust builds up inside the machine.

This is normal

Clean the machine regularly. Open the

doors and remove the sawdust with a

vacuum cleaner.

Sawdust inside the motor housing.

This is normal

Clean the ventilating slots of the motor with

a vacuum cleaner. From time to time re-

move the sawdust to prevent it from being

drawn into the housing.

The machine does not cut at 45 or 90 de-

grees.

1. The table is not at right angles to the

blade.

2. The saw blade is dull or too much pres-

sure was put on the work piece.

1. Adjust the table.

2. Replace the saw blade or put less

pressure on the work piece.

The saw blade can not be properly posi-

tioned on the wheels.

1. The wheels are not in alignment or de-

fective bearing.

2. The blade tracking knob hasn't been

properly adjusted.

3. Inferior saw blade.

1. Replace bearing.

2. Adjust the blade tracking knob (See

ADJUSTMENT instructions).

3. Replace the saw blade.

_ _rr nzlkzhg izamerf jmmcheee_Your _

Gmts_u_ ° pudu[:L _ [lle_unnd and _ Tnrynam d

_llnemJ_=_ q_mrJ_rt. I]k.dtlikp nil _, it tony umquim u_Mm"

from line kz limp_ Thzzlrswhzm _ =i Flz_r _

,#gmeme_ ca. _ ]mu nmnL_ _1 agil_

_'s ih,zl Ilhe llelpair Pmb_dimz _ incllBdes:

Ezped s,_,,ice by our I(].DOD_ mW_ sWe_alis_

!_1 U nFlll_d _ amd zrm,=1_ rot pml_ im=l Mbmrnn ,,:,q

,==,_mmdmmzim

I_ l_mldrEll_Lam_mmlt upb$1_Dl]ifyuLr_m_l l_mluEt

€_r_tluefiJ_d

65 iD_.Gount ulf 25n&4[mm m_ulnr puk_ nf _&_ _=1 neJkdml

m Fast henpu_,p_n_ - _ mn _ g_u_ _m=_nn-

_ SUl=tnurlhcnm n _ _. l"hink _,-,_

=m_a"tnllnng mimers msmunn"

13

Once _uu pmdvme the Repeir Pmkeckzn Agmened. e

_imple phmle cd is,d IhaL itkd_ rnrymn "In_le

You cat cell a_lime dey or nigHL,or sdmlule a meek:e

=m:akdm_ online.

]_,=,,==,,=,,ak,r =.,',j,r,m_undu,ir,a the pm_,,=,,=,d_ p_'iud.

tm rail pmq_e n ful mlhurul. Or. a pmrulm9 udurul mqdim_ uflm-

_ inC_Ia vzi_, ® _ ihs_,_IF_ f_l _el_ils

_11 Seam Canada at 1-_1]10-3_1-4_1_.

._n_uS lumtallali_ S mvi_

R_,-_ pu_.lim_ _ af tmme_=_ia'_. n_nne

du=r upusm_. _ub_r hmmdms,and _Jmr maim- hom_ iimms, in _e

U.S.A_ m-Carm_ _dl 14413_-4-IW-140_L__

Loading ...

Loading ...

Loading ...