Loading ...

Loading ...

Loading ...

CLEAN AIR INTAKE/COOLINGAREAS

Toinsurepropercooling, makesure the

grass screen,cooling fins, and other

externalsurfacesof the engineare kept

cleanat all times.

Every100hours of operation(moreoften

underextremelydusty,dirtyconditions),

removethe blower housingand other

cooling shrouds.Cleanthe coolingfins

and externalsurfaces as necessary.Make

sure the coolingshroudsare reinstalled.

NOTE: Operatingthe enginewith a

blockedgrassscreen, dirty or plugged

cooling fins,and/or coolingshroudsre-

movedwillcauseengine damagedue to

overheating.

AIR FILTER

Yourenginewill not run properly usinga

dirty airfilter, _€lean the foam pre-cleaner

after every 25 hours of operation or every

season. Service paper cartridge every

100 hours of operation or every season,

whichever occurs first.

Service air cleaner more often under dusty

conditions.

• Loosen knob and remove cover.

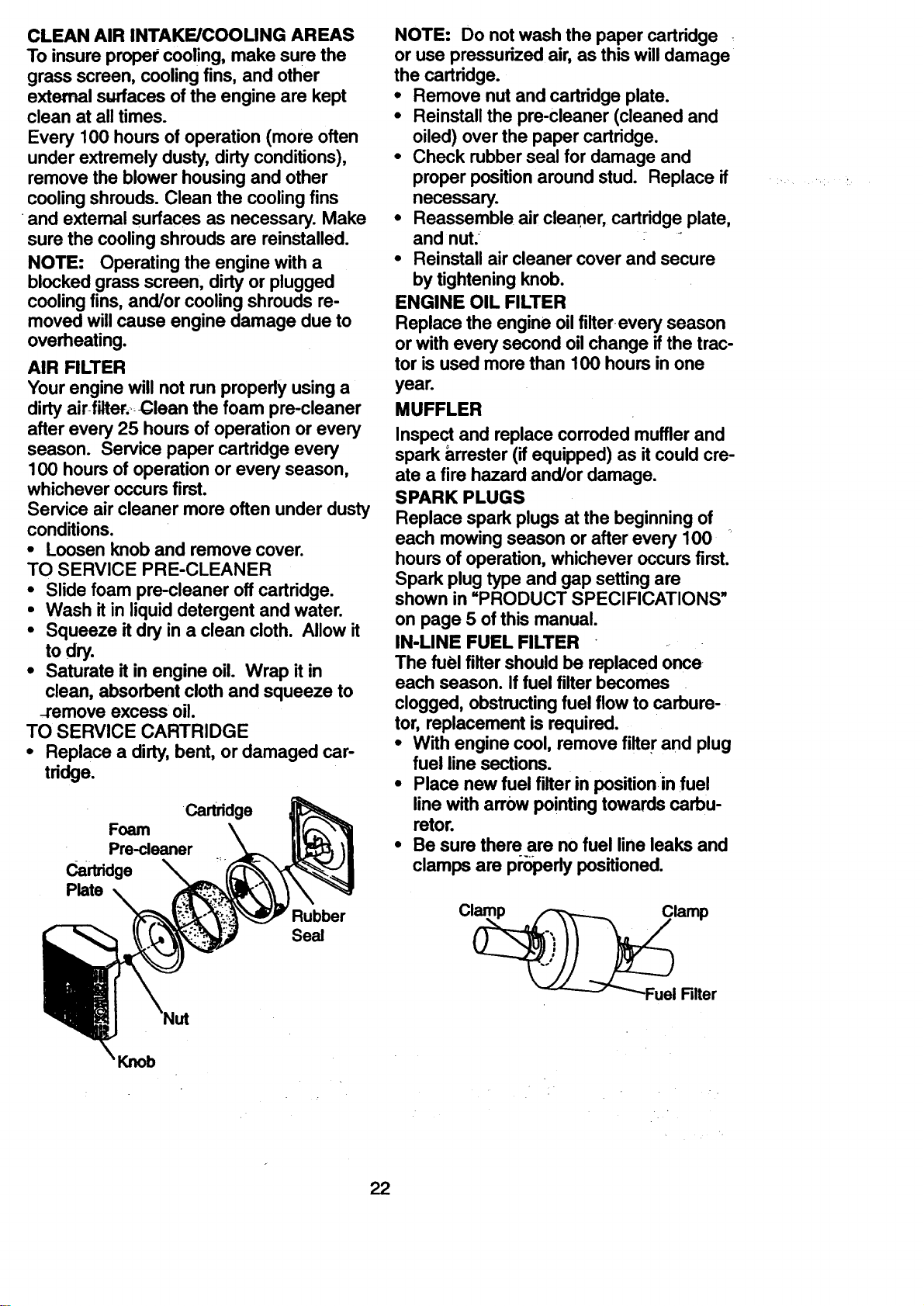

TO SERVICE PRE-CLEANER

• Slide foam pre-cleaner off cartridge.

• Wash it in liquid detergent and water.

• Squeeze it dry in a clean cloth. Allow it

todry.

• Saturate it in engine oil. Wrap it in

clean, absorbent cloth and squeeze to

-remove excess oil.

TO SERVICE CARTRIDGE

• Replace a dirty, bent, or damaged car-

tridge.

Cartridge

Foam

Pre-cleaner

Cartridge

Plate

Rubber

Seal

NOTE: Do not wash the paper cartridge

or use pressurized air, as this will damage

the cartridge.

• Remove nut and cartridge plate.

• Reinstall the pre-cleaner (cleaned and

oiled) over the paper cartridge.

• Check rubber seal for damage and

proper position around stud. Replace if

necessary.

• Reassemble air cleaner, cartridge plate,

and nut.

• Reinstall air cleaner cover and secure

by tightening knob.

ENGINE OIL FILTER

Replace the engine oil filterevery season

or with every second oil change if the trac-

tor is used more than 100 hours in one

year.

MUFFLER

Inspectand replace corrodedmufflerand

spark arrester (ifequipped) as it couldcre-

ate a fire hazard and/or damage.

SPARK PLUGS

Replace spark plugsat the beginningof

each mowingseason or after every 100

hours of operation,whichever occurs first.

Spark plugtype and gap settingare

shown in =PRODUCT SPECIFICATIONS"

on page 5 ofthis manual.

IN-LINE FUEL FILTER

The fuel filter shouldbe replacedonce

each season. If fuel filter becomes

clogged, obstructingfuel flow to carbure-

tor, replacement is required.

• With engine cool, removefilter and plug

fuel linesections.

• Place new fuel filterin positioninfuel

linewitharrowpointingtowardscarbu-

retor.

• Be sure there are no fuel line leaks and

clamps are pl'_perlypositioned.

Clamp

Filter

Knob

22

Loading ...

Loading ...

Loading ...