Loading ...

Loading ...

Loading ...

4

WSM3300

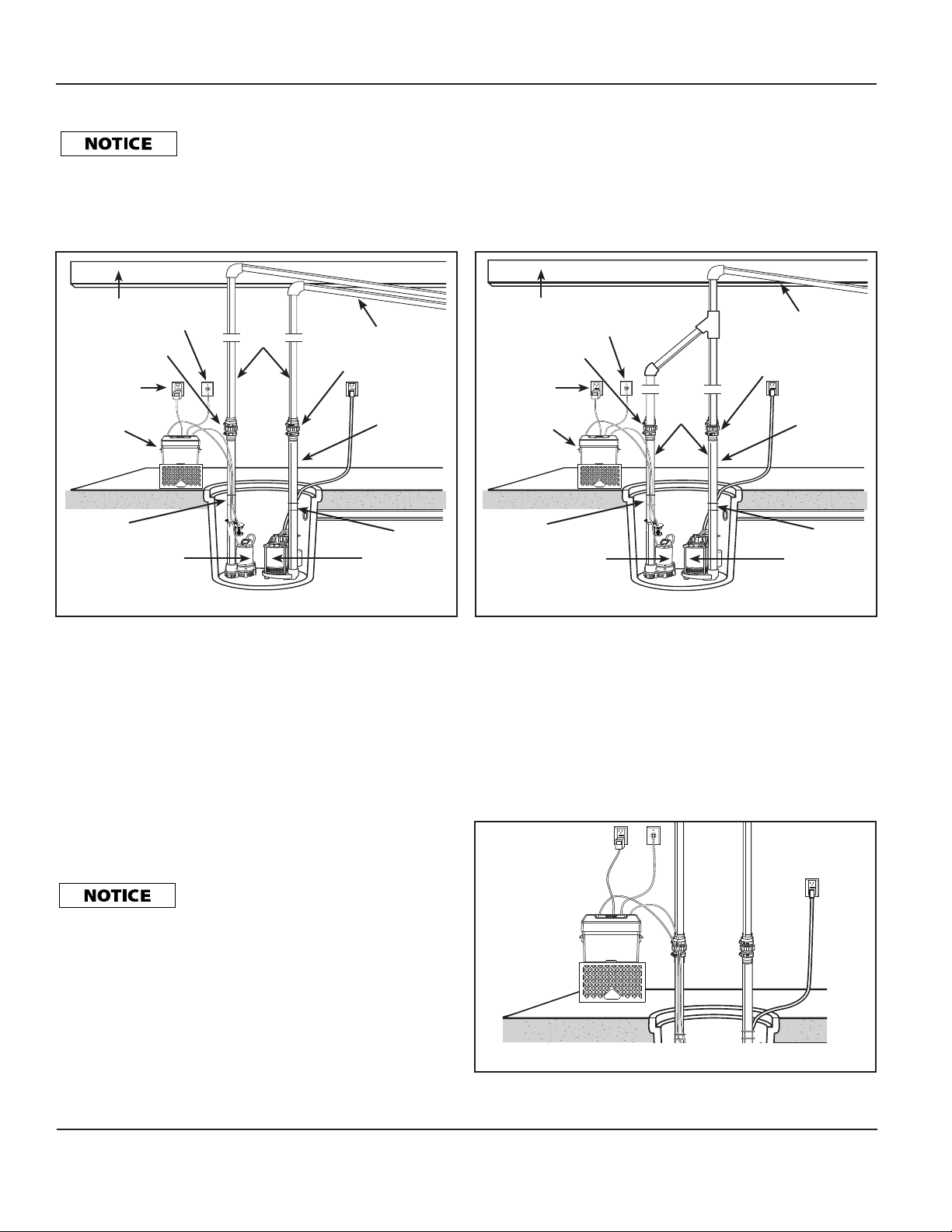

METHOD 2 - See Figure 2

If a separate, dedicated discharge is not possible as in Method

1, the Back-Up DC Pump can be tied into the AC-operated

pump’s discharge pipe by installing a “Y” or "T" connector.

Two check valves will be required.

1. Locate the Back-Up DC Pump on a solid, level surface in the

sump pit. Do not place the pump on a loose or sandy surface.

Small stones or sand may damage the pump resulting in

pump failure.

2. This pump has a 1-1/2 in. NPT discharge. If a 1-1/4 in.

discharge pipe is desired, an adapter (sold separately, part

#66002-WYN1 WAYNE adapter or equivalent) will be

necessary. Smaller diameter piping will reduce pump

flow-rate and performance.

3. A check valve will be required in the discharge line of both

the Main AC pump and the Back-Up DC pump to prevent

recirculation of water into the sump pit. System will not

function without two check valves.

4. Cut a 4 ft. section of 1-1/4 in. or 1-1/2 in. diameter rigid PVC

pipe. Cement 1-1/2 in. pipe to a threaded fitting. Cement

1-1/4 in. pipe into pipe coupling. Attach 1-1/4 in. pipe

section to the Back-Up DC Pump discharge adapter.

5. Screw into pump discharge.

6. Place the pump with the 4 ft. section of PVC pipe on the

sump floor or on an elevated surface if required.

7. Attach a rubber check valve (sold separately) to the top of

the discharge pipe. This will allow the pump or check valve

to be removed easily for servicing.

8. Duplicate the discharge piping arrangement for the primary

AC pump if the existing discharge line has to be adjusted to

accommodate a second pump.

Figure 1 - Method 1 (Preferred Installation)

Do NOT strip or cross thread plastic

fittings or check valves. Flex hose is NOT

recommended. Rigid PVC or metal pipe is required for permanent installation.

9. Glue a 45º elbow to the short pipe on the Back-Up DC

Pump. Glue a “Y” adapter to the short pipe on the existing

pump, as shown in illustration for Method 2.

10. Glue a short piece of PVC pipe between the 45º elbow and the

“Y”.

The remainder of the discharge pipe installation will vary

depending on individual circumstances. Using sound plumbing

practices, route the discharge pipe to an exterior wall by the

shortest distance

.

METHODS 1 AND 2

Install float switch at least 10 in. -12 in. above bottom of sump

pit so that back-up unit turns on only when the water level is

higher than the normal “on” level for main pump. Make sure

power wires and hose clamp ends do not interfere with float

switch, pump inlet, or main pump operation. The back-up

pump must not be allowed to run dry except during the 20

second "auto-test. Incoming water can not flow directly onto

the float switch. Failure to position properly may cause improper

operation. Position the float switch so that it will not interfere

with any portion of the plumbing, wiring, or sump pit. Check for

clearance by lifting both floats.

Figure 2 - Method 2 (Alternate Installation)

Floor Joist

Rigid

PVC

Pipe

Transformer

Check Valve

Check Valve

Primary Pump

Back-Up DC Pump

1-1/4 in.

or

1-1/2 in.

PVC Pipe

Slope Pipe Down

Floor Joist

Rigid

PVC

Pipe

Transformer

Check Valve

Check Valve

Primary Pump

1-1/4 in.

or

1-1/2 in.

PVC Pipe

Slope Pipe Down

Phone Jack

Phone Jack

12 Volt

Advanced

Notification

System

12 Volt

Advanced

Notification

System

Back-Up DC Pump

Operating Instructions and Parts Manual

Figure 3 - 12 Volt Advanced Notification System elevated

Zip Tie

Zip Tie

Zip Tie

Zip Tie

Check valves MUST be installed in the

discharge line of both the main AC pump and

the back-up DC pump. Failure to install the check valves MAY allow

water to recirculate into the sump pit. See Figures 1 and 2.

www.waynepumps.com

Loading ...

Loading ...

Loading ...