Loading ...

Loading ...

Loading ...

7

Original Instructions

Multi II

Technical specifi cations

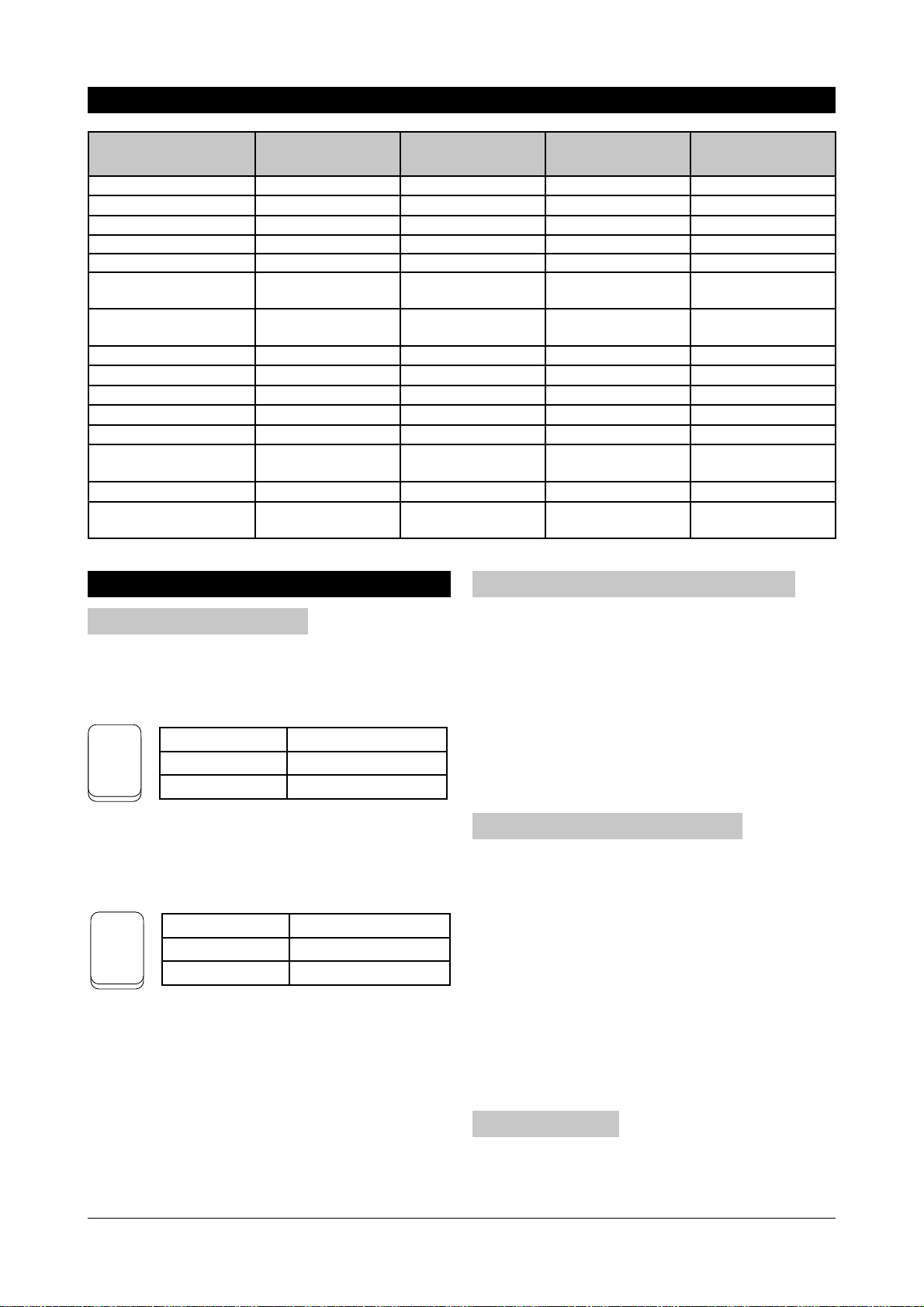

Model Multi 22 Multi 22 T Inox Multi 30 T Inox Multi 50 Inox

Container material

PP INOX INOX INOX

Voltage (V)

220 - 240 220 - 240 220 - 240 220 - 240

PNOM (W)

1130 1130 1260 1260

Pmax (W) 1200 1200 1400 1400

Max Vacuum, kPa/bar 20/200 20/200 21/210 21/210

Max Suction power -

machine, W

270 270 292 292

Sound power

(EN 60704-2-1), dB(A)

85 85 87 87

Tank size, L

22 22 30 50

Net fi lling dry, in bag, L

9 9 13 20

Net fi lling liquid, L

14 14 20 36

Filter indicator

yes yes yes yes

Push to Clean

yes yes

Power out, max 1100

W

yes yes

Auto on/off

yes yes

Variable suction

control

yes

Operational instructions

Using the vacuum cleaner

On/Off - position “E”

Switch “0-I”

Switch position Function

I On

0 Off

Powertool Auto On/Off - position “A”

Switch “0-I”

Switch position Function

I On

0 Off

The machine provides two modes of operation:

vacuuming and blowing.

When using the machine for vacuuming, the hose is

connected to “G”. When using the machine for blow-

ing, the hose is connected to “H”.

The machine is turned on or off at switch “E”.

When running and operational the light in “B” will not

light. The light “B” will light when a drop in suction

performance occurs due to a dirty fi lter.

I

0

Cleaning the fi lter with Push to Clean*)

If the light “B” is turned on, the fi lter may be clogged.

1. Hold one hand against the end of the hose to form

a closed wall. Push the “Push to Clean” button “C”

for 2-3 seconds to let the machine clean the fi lter.

Wait for 3-5 seconds and repeat Step 1, max. 3

times.

2. If the indicator still lights, the cause may lie in a

too heavily clogged fi lter. Occasionally a light rinse

is suffi cient. If not, then replace the fi lter by a new

one.

Filter change (ref. illu. 4, page 2)

1. Open the machine so the fi lter is accessible.

2. Unscrew the tensioning plate “M” to release the

fi lter.

3. Remove the fi lter and replace it by a new one.

4. Tighten tensioning plate (turn right). Make sure

the threads on the tensioning plate are aligned

properly with the threads on the machine. Tighten

the tensioning plate fi rmly so the fi lter seals make

a closed connection to the machine. Beware not

to over-tighten the tensioning plate.

5. Assemble the machine again making sure the mo-

tor head has a proper fi t to the container.

Dust bag change

1. Open the machine so the dust bag is accessible.

2. Remove the old dust bag.

3. Gently slide the new dust bag over the angled

I

0

Loading ...

Loading ...