Loading ...

Loading ...

Loading ...

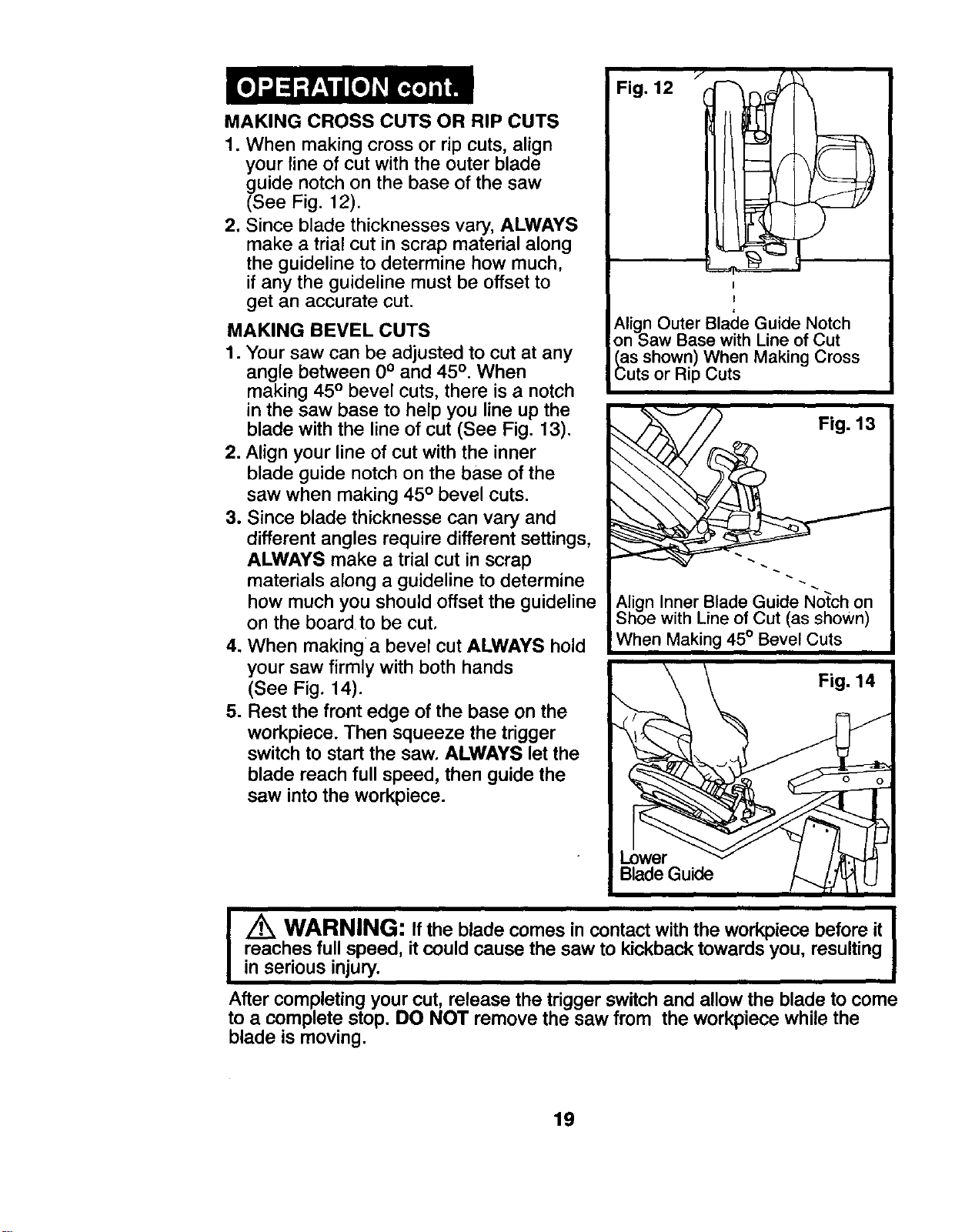

MAKING CROSS CUTS OR RiP CUTS

1. When making cross or rip cuts, align

your line of cut with the outer blade

guide notch on the base of the saw

(See Fig. 12).

2. Since blade thicknesses vary, ALWAYS

make a trial cut in scrap material along

the guideline to determine how much,

if any the guideline must be offset to

get an accurate cut.

MAKING BEVEL CUTS

1. Your saw can be adjusted to cut at any

angle between 0° and 45°. When

making 45° bevel cuts, there is a notch

in the saw base to help you line up the

blade with the line of cut (See Fig. 13).

2. Align your line of cut with the inner

blade guide notch on the base of the

saw when making 45° bevel cuts.

3. Since blade thicknesse can vary and

different angles require different settings,

ALWAYS make a trial cut in scrap

materials along a guideline to determine

how much you should offset the guideline

on the board to be cut.

4. When makinga bevel cut ALWAYS hold

your saw firmly with both hands

(See Fig. 14).

5. Rest the front edge of the base on the

workpiece. Then squeeze the trigger

switch to start the saw. ALWAYS let the

blade reach full speed, then guide the

saw into the workpiece.

Fig. 12

Align Outer Blade Guide Notch

on Saw Base with Line of Cut

hasshown) When Making Cross

uts or Rip Cuts

_ Fig. 13

Align InnerBlade Guide I_otch on

Shoe with Line of Cut (as shown)

When Making 45° Bevel Cuts

WARNING: If the blade comes in contact with the workpiece before it I

reaches full speed, it could cause the saw to kickback towards you, resulting

Iin serious injury.

After completing your cut, release the trigger switch and allow the blade to come

to a complete stop. DO NOT remove the saw from the workpiece while the

blade is moving.

19

Loading ...

Loading ...

Loading ...