Loading ...

Loading ...

Loading ...

1.PlaceboilerintheselecledIocalion(asnearchimneyaspossible.)Your

boilerisshippedassembled.YouneedonlyIoinsfalltheReliefValveand

adrainlinetocarryanywalerorsteamIoadrain.

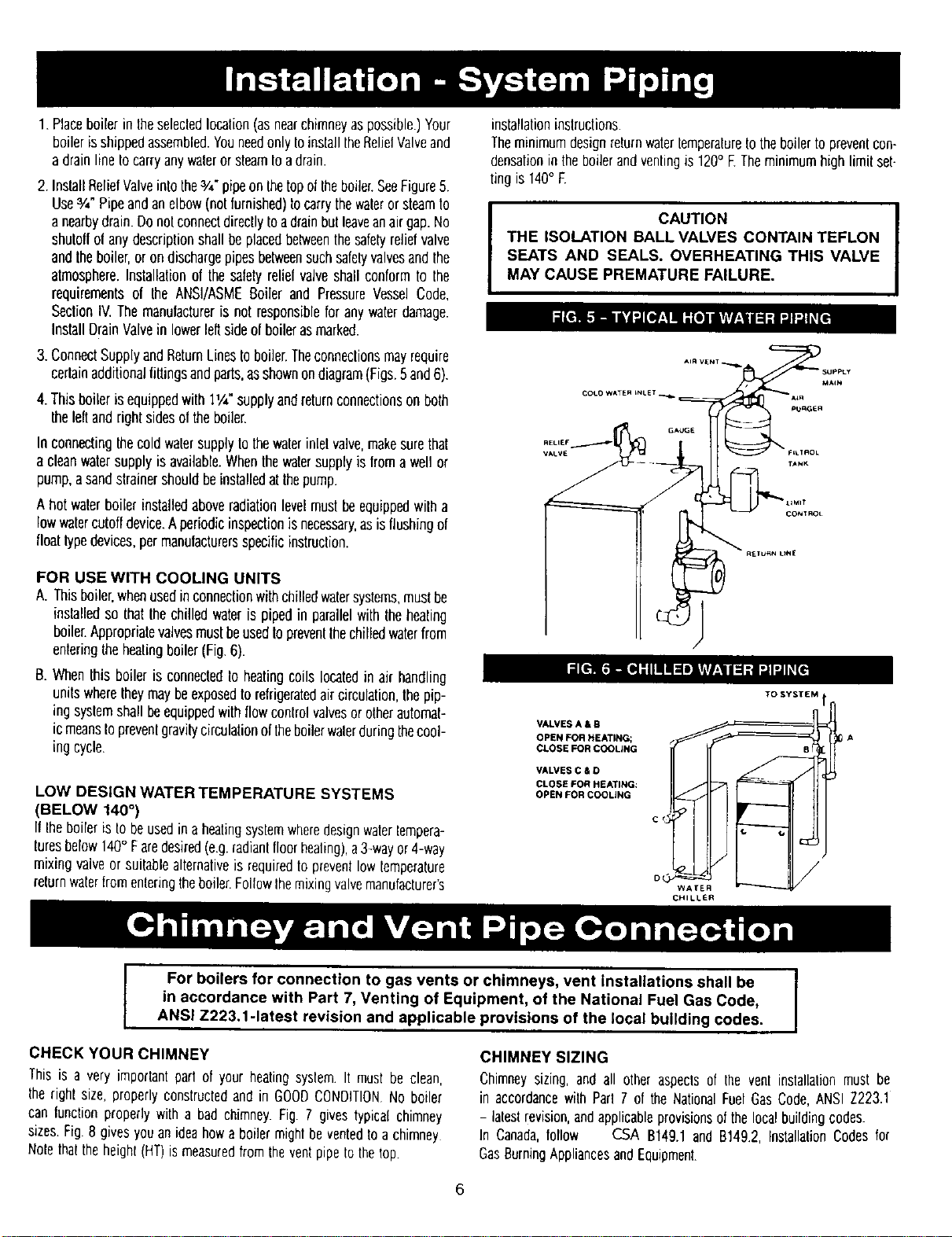

2.InstallRelielValveintothe3/,,-pipeonthetopol Iheboiler.SeeFigure5.

Use¾" Pipeandanelbow(nolfurnished)tocarrythewalerorsteamto

anearbydrain.Donotconnectdirectlytoadrainbulleaveanairgap.No

shutollol anydescriptionshallbeplacedbetweenthesafdyrebelvalve

andtheboiler,or ondischargepipesbetweensuchsafetyvalvesandthe

atmosphere.Installationol thesafetyrelielvalveshallconformto the

requirementsof the ANSI/ASMEBoiler and PressureVesselCode,

SeclionIV.Themanulactureris notresponsibleforanywaterdamage.

InstallDrainValvein lowerleftsideofboilerasmarked.

3.ConnectSupplyandReturnLinestoboiler.Theconneclionsmayrequire

certainadditionalfiltingsandparts,asshownondiagram(Figs.5and6).

4.Thisboileris equippedwilh 11/4"supplyandreturnconnectionsonboth

theleftandrightsidesol theboiler.

Inconnectingthecoldwatersupplytothewalerinlelvalve,makesurethat

a cleanwalersupplyis available.Whenthewatersupplyis froma weftor

pump,asandstrainershouldbeinstalledatthepump.

A hotwalerboiler installedaboveradiationlevelmustbeequippedwilha

lowwatercutoffdevice.A periodicinspectionisnecessary,asisflushingof

floattypedevices,permanufacturersspecificinstruction.

FOR USE WITH COOUNG UNITS

A. Thisboiler,whenusedinconnectionwithchilledwatersystems,mustbe

installedso that thechilledwateris pipedin parallelwiththeheating

boiler.Appropriatevalvesmustbeused1oprevenlthechilledwaterfrom

enteringtheheatingboiler(Fig.6).

B. Whenthisboiler is connectedto heatingcoils locatedin air handling

unitswheretheymaybeexposedtorefrigeratedaircirculation,thepip-

ing syslemshallbeequippedwithflowcontrolvalvesorotherautomaf-

icmeanstoprevenlgravgycirculationoftheboilerwalerduringthecool-

ing cycle.

LOW DESIGN WATER TEMPERATURE SYSTEMS

(BELOW 140°)

If Iheboileristobeusedin aheatingsysfemwheredesignwaterlempera-

luresbelow140° Faredesired(e.g.radianlfloorhealing),a3-wayor4-way

mixingvalveor suitablealternativeis requiredtopreventlowfemperature

returnwaterfromenleringtheboiler.FollowIhemixingvalvemanufacturer's

installationinstructions.

TheminimumdesignreturnwaterLemperatureIotheboilertoprevenlcon-

densationin theboilerandventingis120° ETheminimumhigh limilset-

tingis 140° F.

I CAUTION

THE ISOLATION BALL VALVES CONTAIN TEFLON

SEATS AND SEALS. OVERHEATING THIS VALVE

MAY CAUSE PREMATURE FAILURE.

COt.o WATE_ LNLET.

VALVES A & B

OPEN FOR HEATING;

CLOSE FOR COOLING

VALVES C & O

CLOSE FOR HEATING:

OPEN FOR COOLING

TO SYSTEM

cd

WAFER

CHILLER

For boilers for connection to gas vents or chimneys, vent Installations shall be

in accordance with Part 7, Venting of Equipment, of the National Fue| Gas Code,

ANSI Z223.1-1atest revision and applicable provisions of the local building codes.

CHIMNEY SIZING

CHECK YOUR CHIMNEY

Thisis a very imporfantpartof yourheatingsystem It mustbe clean,

therightsize,properlyconstructedandin GOODCONDITIONNo boiler

canlunctionproperlywith a bad chimney.Fig. 7 givestypicalchimney

sizes.Fig.8 givesyouanideahowa boilermightbe ventedto achimney

Nofetha_theheight(HT)ismeasuredfromtheventpipetothelop.

Chimneysizing,and all otheraspectsof the vent installationmustbe

in accordancewith Part7 of the NationalFuelGasCode,ANSIZ223.1

- laleslrevision,andapplicableprovisionsofthelocalbuildingcodes.

In Canada,follow CSA B149.1and B149.2,InstallabonCodesfor

GasBurningAppliancesandEquipment.

6

Loading ...

Loading ...

Loading ...