Loading ...

Loading ...

Loading ...

13

9b

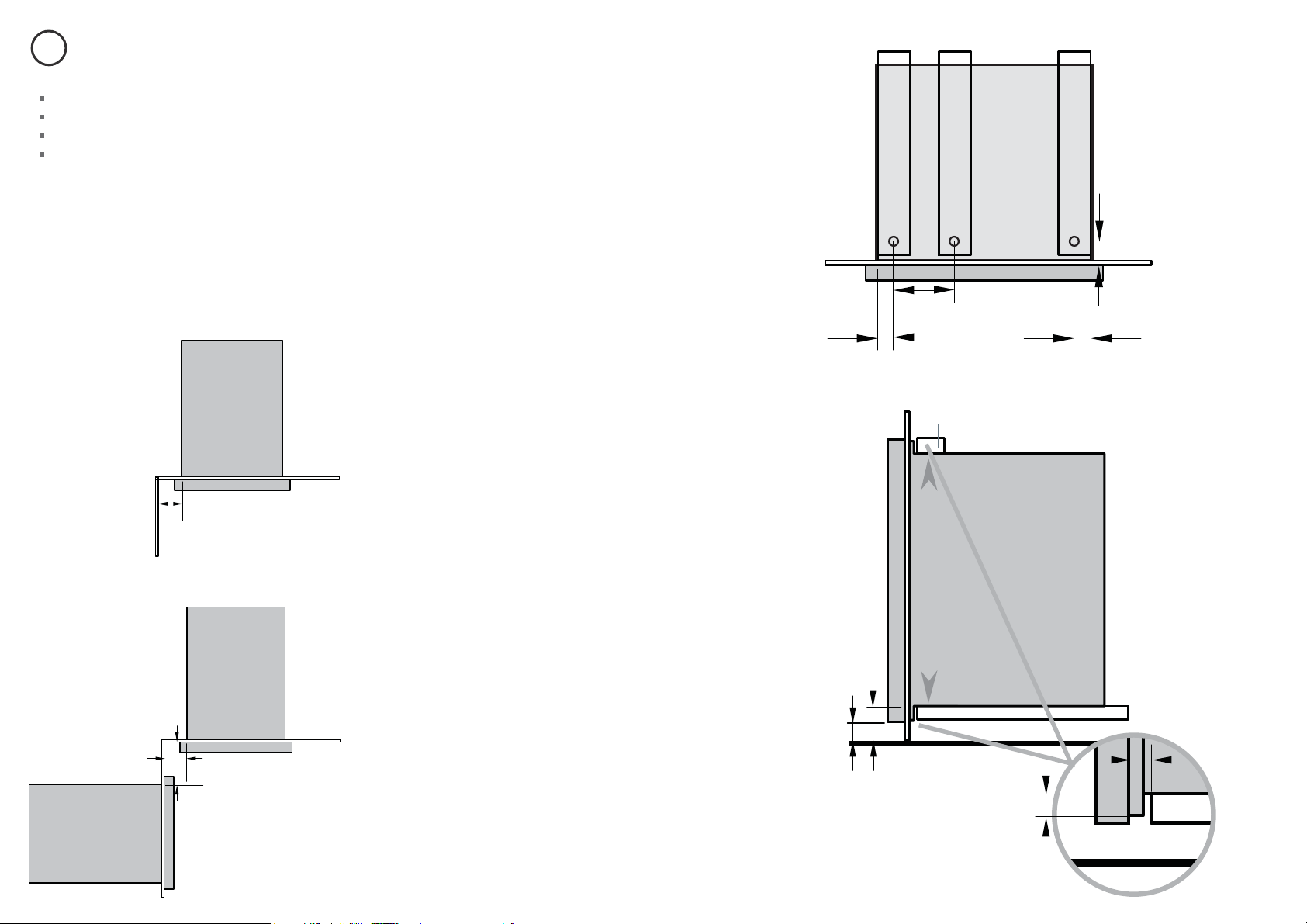

PREPARE THE CAVITY

Ensure the cavity is level, square and able to support the weight of the product when full.

Any cabinet and/or ground preparation must be completed prior to installation.

All support structures must be constructed of materials resistant to moisture damage.

Do no use harsh products (acid, solvent, sealers) around this product.

1

Depending on your construction, place either a shelf or at least two (min 2” (51 mm) wide) moisture

resistant supports in the cutout, paying special attention to the “step” on the base of the chassis.

Ensure all support boards are flat and level.

2

Provide a similiar support above the chassis to screw up into as shown.

m

(1

1 ⁄”

(35 mm)

3 ¾”

(95 mm)

10 ¼”

(260 mm)

3 ¾”

(95 mm)

min. ⁄”

(11 mm)

min. 1⁄”

(30 mm)

⁄” (16 mm)

)

Provide a support above the

chassis to screw up into

There is an additional

“step” on the pantry

chassis that must be

considered when

locating the supports

Allow min. 1 ⁄” (28mm)

clearance from the cutout to a

corner

Pantry unit and drawer / waste bin

Allow min. 6 1/2” (165mm) clearance from the cutout

to the corner for each product.

Pantry unit and Beverage chiller with bottle holder

Allow min. 9 1/2” (241mm) clearance from the cutout

to the corner for each product

min. 1 ⁄” (28 mm)

min. 6 ½” (165 mm)

min. 6 ½” (165 mm)

CORNER INSTALLATIONS

CORNER INSTALLATIONS WITH TWO PRODUCTS (INCLUDING PANTRY)

measured from

back of frame

Loading ...

Loading ...

Loading ...