Loading ...

Loading ...

Loading ...

Cleaning the air filter:

A dirty air filter decreases engine per-

formance and increases fuel consump-

tion and harmful emissions. Always

clean after every 5 hours of operation.

1. Clean the cover and the area

around it to keep debris from falling

into the carburetor chamber when

the cover is removed.

2. Remove parts as illustrated.

NOTE: Do not clean filter in gasoline

or other flammable solvent. Doing so

can create a fire hazard or produce

harmful evaporative emissions.

3. Wash the filter in soap and water.

4. Allow filter to dry.

5. Add a few drops of oil to the filter;

squeeze filter to distribute oil.

6. Replace parts.

REPLACE SPARK PLUG

Replace spark plug each year to en-

sure the engine starts easier and runs

better. Set spark plug gap at 0.025 in.

Ignition timing is fixed, nonadjustable.

1. Twist, then pull off spark plug boot.

2. Remove spark plug from cylinder

and discard.

3. Replace with Champion RCJ-8Y

spark plug and tighten with a 3/4 in.

socket wrench (10-12 ft.-Ibs).

4. Reinstall the spark plug boot.

REPLACE FUEL FILTER

To replace fuel filter, drain unit by run-

ning it dry of fuel, then remove fuel cap

and its connected retainer from tank.

Pull filter from tank and remove it from

the fuel line. Install new fuel filter on

fuel line; reinstall parts.

We recommend all service and adjust- 2.

ments not listed in this manual be per-

formed by your Sears Service Center.

3.

CARBURETOR ADJUSTMENT

Carburetor adjustment is critical and if

done improperly can permanently dam-

age the engine as well as the carburetor.

If you require further assistance or are

unsure about performing this procedure,

call our customer assistance help line at

1-800-285-5878.

Old fuel, a dirty air filter, a dirty fuel filter,

or flooding may give the impression of

an improperly adjusted carburetor. Check

these conditions before adjusting the

carburetor.

The carburetor has been carefully set at

the factory. Adjustments may be neces-

sary if you notice any of the following

conditions:

• Engine will not idle. See IDLE SPEED

and MIXTURE under adjusting

procedure.

• Engine dies or hesitates instead of

accelerating. See ACCELERATION

CHECK under adjusting procedure.

• Loss of power. See MIXTURE under

adjusting procedure.

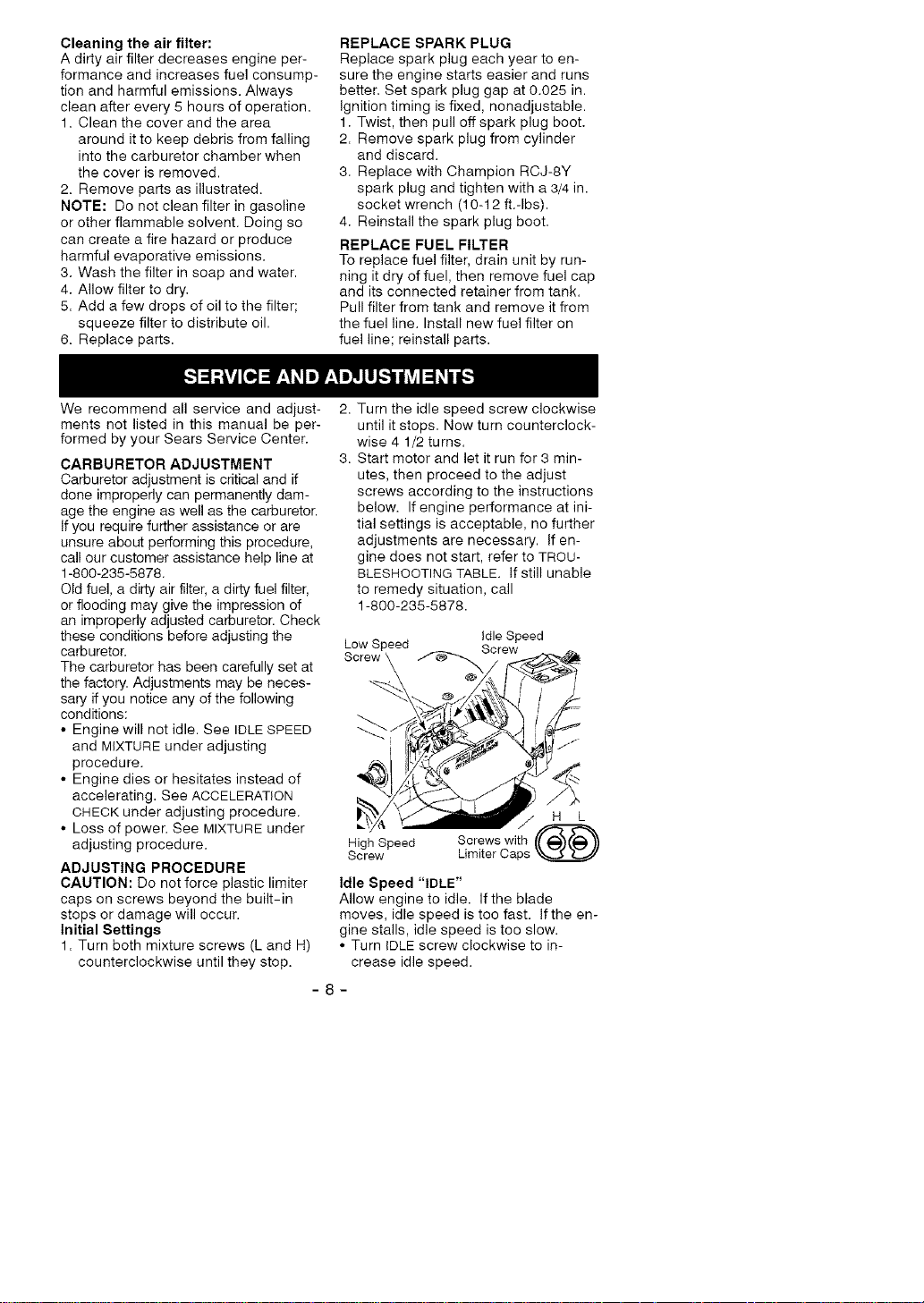

ADJUSTING PROCEDURE

CAUTION: Do not force plastic limiter

caps on screws beyond the built-in

stops or damage will occur.

Initial Settings

1. Turn both mixture screws (L and H)

counterclockwise until they stop.

Turn the idle speed screw clockwise

until it stops. Now turn counterclock-

wise 4 1/2 turns.

Start motor and let it run for 3 min-

utes, then proceed to the adjust

screws according to the instructions

below. If engine performance at ini-

tial settings is acceptable, no further

adjustments are necessary. If en-

gine does not start, refer to TROU-

BLESHOOTING TABLE. If still unable

to remedy situation, call

1-800-235-5878.

Low Speed

Idle Speed

Screw

High Speed

Screw

H L

Screws with

Idle Speed "IDLE"

Allow engine to idle. If the blade

moves, idle speed is too fast. If the en-

gine stalls, idle speed is too slow.

• Turn IDLE screw clockwise to in-

crease idle speed.

-8-

Loading ...

Loading ...

Loading ...