Loading ...

Loading ...

Loading ...

s

PANEL

- SECONDAR Y DRAIN W_TH

AppRoPREATE TRAp REQUIRED

(USE FACTORY KIT OR

PRIMARY TRAP RE U[RE_ FIELD SUPPUED TRAP)

(USE FACTORY KIT OR

FIELD SUPPUED TRAP OF

SUFFICIENT DEPTH

STANDARD P TRAPS ARE

NOT $UFF[C[ENT SEE

FIGURE OF RECOMMENDED

CONDENSATE TRAP)

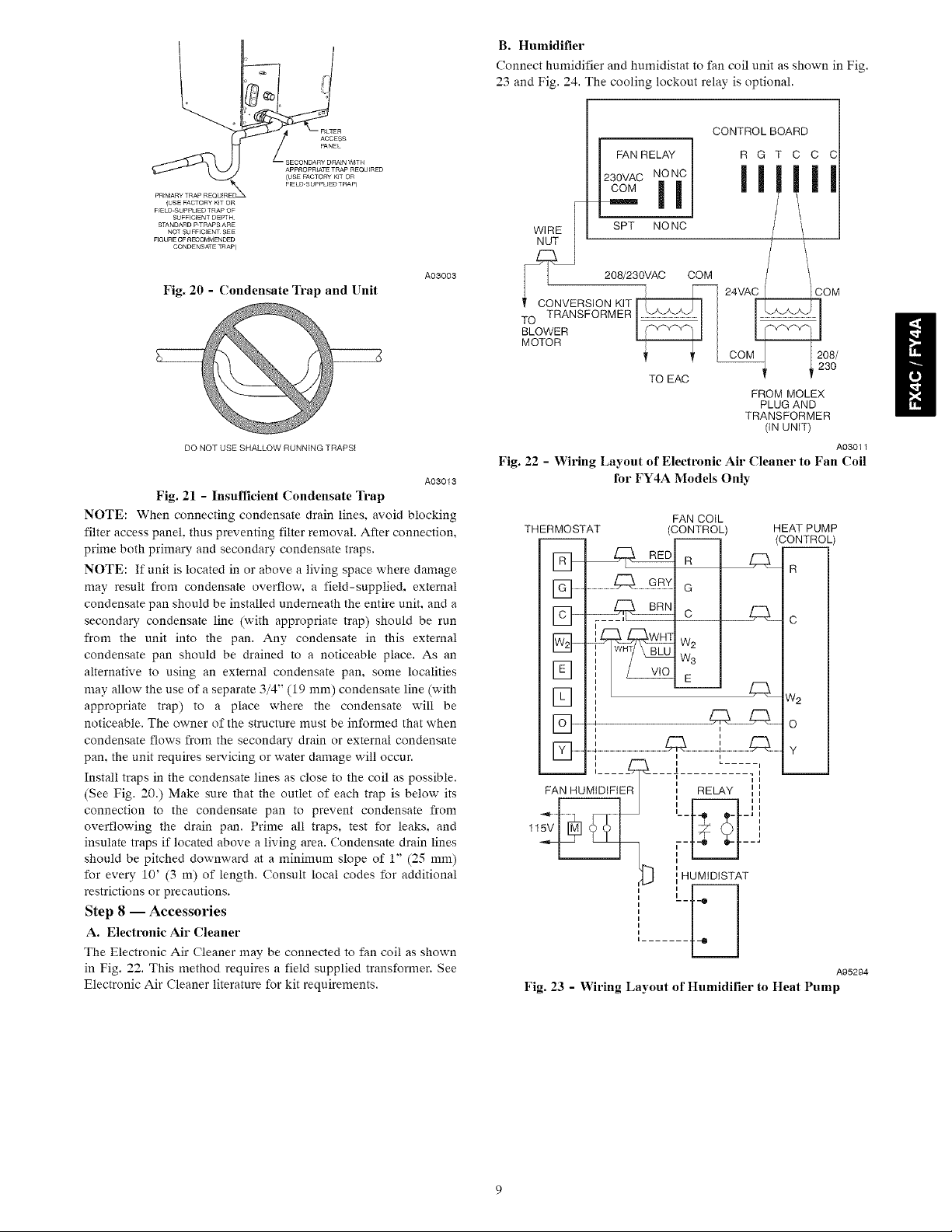

Fig. 20 - Condensate Trap and Unit

A03003

DO NOT USE SHALLOW RUNN{NG TRAPS!

A03013

Fig. 21 - Insufficient Condensate Trap

NOTE: When connecting condensate drain lines, avoid blocking

filter access panel, thus preventing filter removal. After connection,

prime both primary and secondary condensate traps.

NOTE: If unit is located in or above a living space where damage

may result from condensate overflow, a field-supplied, external

condensate pan should be installed underneath the entire unit. and a

secondary condensate line (with appropriate trap) should be run

from the unit into the pan. Any condensate in this external

condensate pan should be drained to a noticeable place. As an

alternative to using an external condensate pan, some localities

may allow the use of a separate 3/4" (19 mm) condensate line (with

appropriate trap) to a place where the condensate will be

noticeable. The owner of the structure must be informed that when

condensate flows from the secondary drain or external condensate

pan, the unit requires servicing or water damage will occur.

Install traps in the condensate lines as close to the coil as possible.

(See Fig. 20.) Make sure that the outlet of each trap is below its

connection to the condensate pan to prevent condensate from

overflowing the drain pan. Prime all traps, test for leaks, and

insulate traps if located above a living area. Condensate drain lines

should be pitched downward at a minimum slope of 1" (25 mm)

for every 10' (3 m) of length. Consult local codes for additional

restrictions or precautions.

Step 8 -- Accessories

A. Electronic Air Cleaner

The Electronic Air Cleaner may be connected to fan coil as shown

in Fig. 22. This method requires a field supplied transformer. See

Electronic Air Cleaner literature for kit requirements.

B. Humidifier

Connect humidifier and humidistat to fan coil unit as shown in Fig.

23 and Fig. 24. The cooling lockout relay is optional.

CONTROL BOARD

2?gAcFANRELAY I R G T C C C

NONCIIlllll

FROM MOLEX

PLUGAND

TRANSFORMER

(IN UNIT)

A03011

Fig. 22 - WMng Layout of Electronic Air Cleaner to Fan Coil

for FY4A Models Only

THERMOSTAT

] .............

[]

[]

] .............

FAN COIL

(CONTROL)

.............................G

W3

i

i

......... i.......... ii

FAN HUMtDtFIE , RELAY ,,

....

--L--'

,JJ , HUMIDtSTAT

HEAT PUMP

(CONTR....OL)

R

W2

O

Y

A95294

Fig. 23 - Wiring Layout of Humidifier to Heat Pump

Loading ...

Loading ...

Loading ...