Loading ...

Loading ...

Loading ...

8. Recheck both support channels to make sure

that tightening screws did not affect the accuracy

of the adjustment.

9. Elevate saw and return motor to horizontal posi-

tion to provide clearance for installation of front

(work) table.

INSTALLATION OF FRONT (WORK)

TABLE

.

.

.

.

.

.

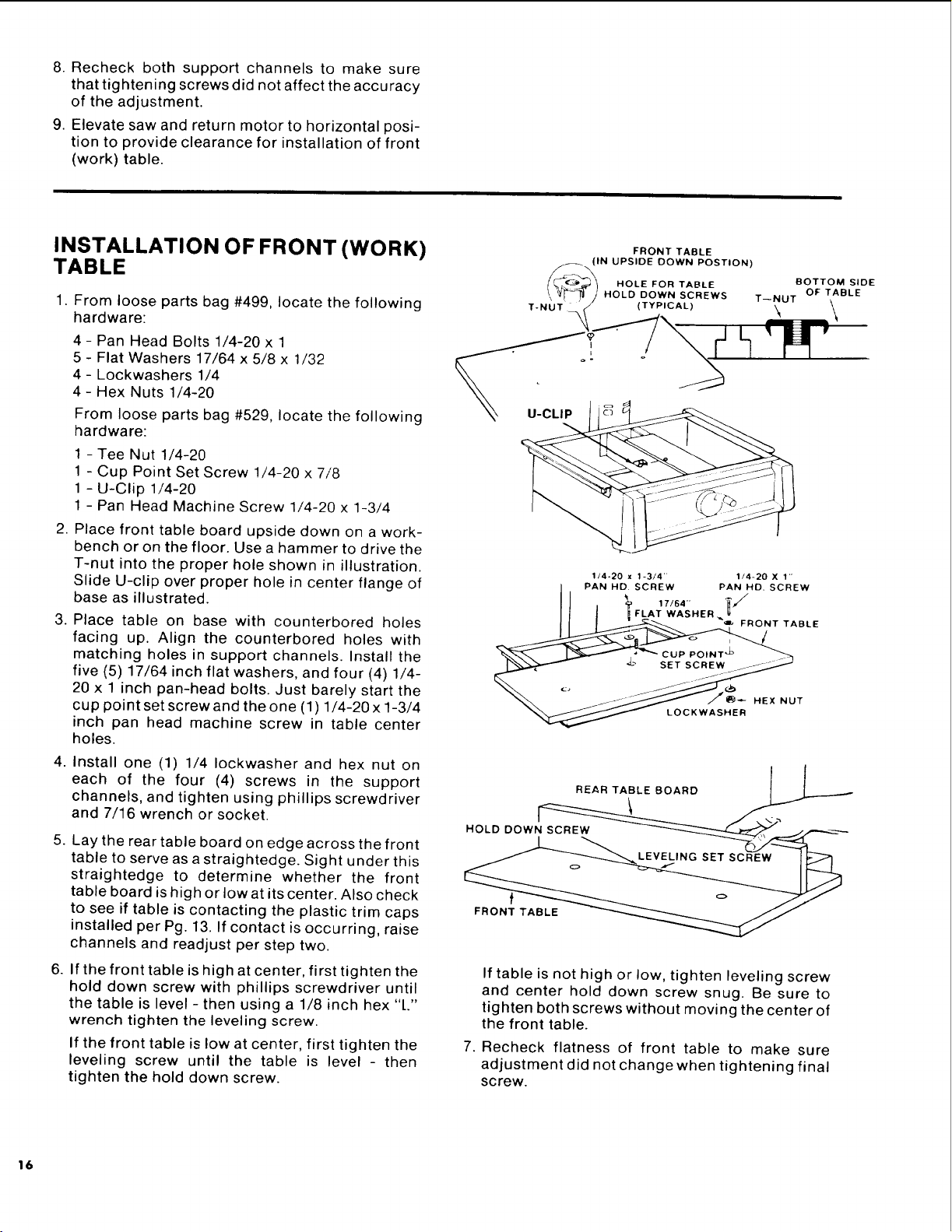

From loose parts bag #499, locate the following

hardware:

4- Pan Head Bolts 1/4-20 x 1

5- Flat Washers 17/64 x 5/8 x 1/32

4 - Lockwashers 1/4

4- Hex Nuts 1/4-20

From loose parts bag #529, locate the following

hardware:

1 - Tee Nut 1/4-20

1 - Cup Point Set Screw !/4-20 x 7/8

1 - U-Clip 1/4-20

1 - Pan Head Machine Screw 1/4-20 x 1-3/4

Place front table board upside down on a work-

bench or on the floor. Use a hammer to drive the

T-nut into the proper hole shown in illustration.

Slide U-clip over proper hole in center flange of

base as illustrated.

Place table on base with counterbored holes

facing up. Align the counterbored holes with

matching holes in support channels. Install the

five (5) 17/64 inch flat washers, and four (4) 1/4-

20 x 1 inch pan-head bolts. Just barely start the

cup point set screw and the one (1) 1/4-20 x 1-3/4

inch pan head machine screw in table center

holes.

Install one (1) 1/4 Iockwasher and hex nut on

each of the four (4) screws in the support

channels, and tighten using phillips screwdriver

and 7/16 wrench or socket.

Lay the rear table board on edge across the front

table to serve as a straightedge. Sight under this

straightedge to determine whether the front

table board is high or low at its center. Also check

to see if table is contacting the plastic trim caps

installed per Pg. 13. If contact is occurring, raise

channels and readjust per step two.

If the front table is high at center, first tighten the

hold down screw with phillips screwdriver until

the table is level - then using a 1/8 inch hex "L"

wrench tighten the leveling screw.

If the front table is low at center, first tighten the

leveling screw until the table is level - then

tighten the hold down screw.

FRONT TABLE

.. (IN UPSIDE DOWN POSTION)

HOLE FOR TABLE

/ _/[_J_ J HOLD DOWN SCREWS T--NUT

\ . /

T-NUT _ (TYPICAL) \

u-cuP

BOTTOM SIDE

OF TABLE

\

F

1/4o20 x 1-3/4" 1/4-20 X 1'"

PAN HD. SCREW PAN NO. SCREW

FLAT WASHER _ u

FRONT TABLE

_ HEX NUT

LOCKWASHER

HOLD DOW_

REAR TABLE BOARD '_:',

If table is not high or low, tighten leveling screw

and center hold down screw snug. Be sure to

tighten both screws without moving the center of

the front table.

7. Recheck flatness of front table to make sure

adjustment did not change when tightening final

screw.

16

Loading ...

Loading ...

Loading ...