Loading ...

Loading ...

Loading ...

9

ENGLISH

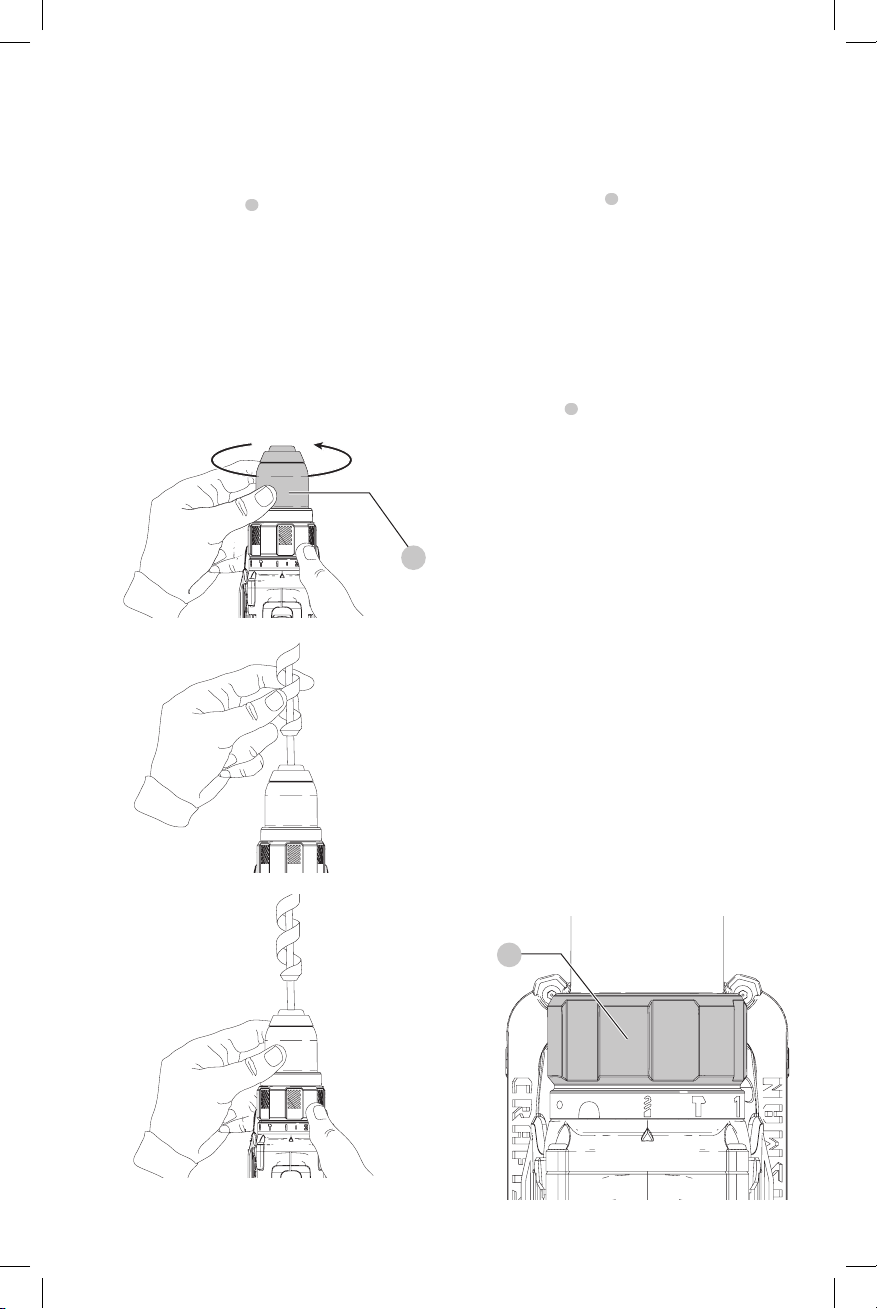

Keyless Chuck (Fig. G–I)

WARNING: Make certain the battery pack is removed

to prevent tool actuation before installing or

removingaccessories.

To insert a drill bit or other accessory:

1. Grasp the keyless chuck

6

and rotate it in the

counterclockwise direction, as viewed from the

chuckend.

2. Insert the bit or other accessory fully into the chuck, and

tighten securely by rotating the chuck in the clockwise

direction as viewed from the chuck end.

WARNING: Do not attempt to tighten or loosen drill

bits (or any other accessory) by gripping the front

part of the chuck and turning the tool on. Damage

to the chuck and personal injury may occur when

changingaccessories.

Fig.G

6

Fig.H

Fig.I

LED Work Light (Fig. A)

WARNING: Do not place the light in a position

which may cause anyone to intentionally or

unintentionally stare into the light. Serious eye

injury couldresult.

There is an LED worklight

5

. The worklight is activated

when the trigger switch is depressed, and will automatically

turn off approximately 20 seconds after the trigger switch

is released. If the trigger switch remains depressed, the

worklight will remainon.

NOTE: The worklight is for lighting the immediate work

surface and is not intended to be used as aflashlight.

Drilling (Fig. J)

NOTICE: If drilling thin material, use a wood “back-

up” block to prevent damage to thematerial.

1. Turn the collar

3

to the drillsymbol.

2. Use sharp drill bits only. For MASONRY, such as brick,

cement, cinder block, etc., use carbide-tipped bits rated

for percussiondrilling.

3. Always apply pressure in a straight line with the bit. Use

enough pressure to keep drill biting, but do not push

hard enough to stall the motor or deflect thebit.

4. Hold tool firmly with both hands to control the twisting

action of the drill. If model is not equipped with side

handle, grip drill with one hand on the handle and one

hand on the batterypack.

WARNING: Drill may stall if overloaded causing a

sudden twist. Always expect the stall. Grip the drill

firmly to control the twisting action and avoidinjury.

5. IF DRILL STALLS, it is usually because it is being

overloaded or improperly used. RELEASE TRIGGER

IMMEDIATELY, remove drill bit from work, and

determine cause of stalling. DO NOT DEPRESS

TRIGGER ON AND OFF IN AN ATTEMPT TO START A

STALLED DRILL — THIS CAN DAMAGE THEDRILL.

6. To minimize stalling or breaking through the material,

reduce pressure on drill and ease the bit through the

last fractional part of thehole.

7. Keep the motor running when pulling the bit back out

of a drilled hole. This will help preventjamming.

Fig.J

3

Loading ...

Loading ...

Loading ...