Loading ...

Loading ...

Loading ...

assembly and alignment

ASSEMBLY AND ALIGNMENT

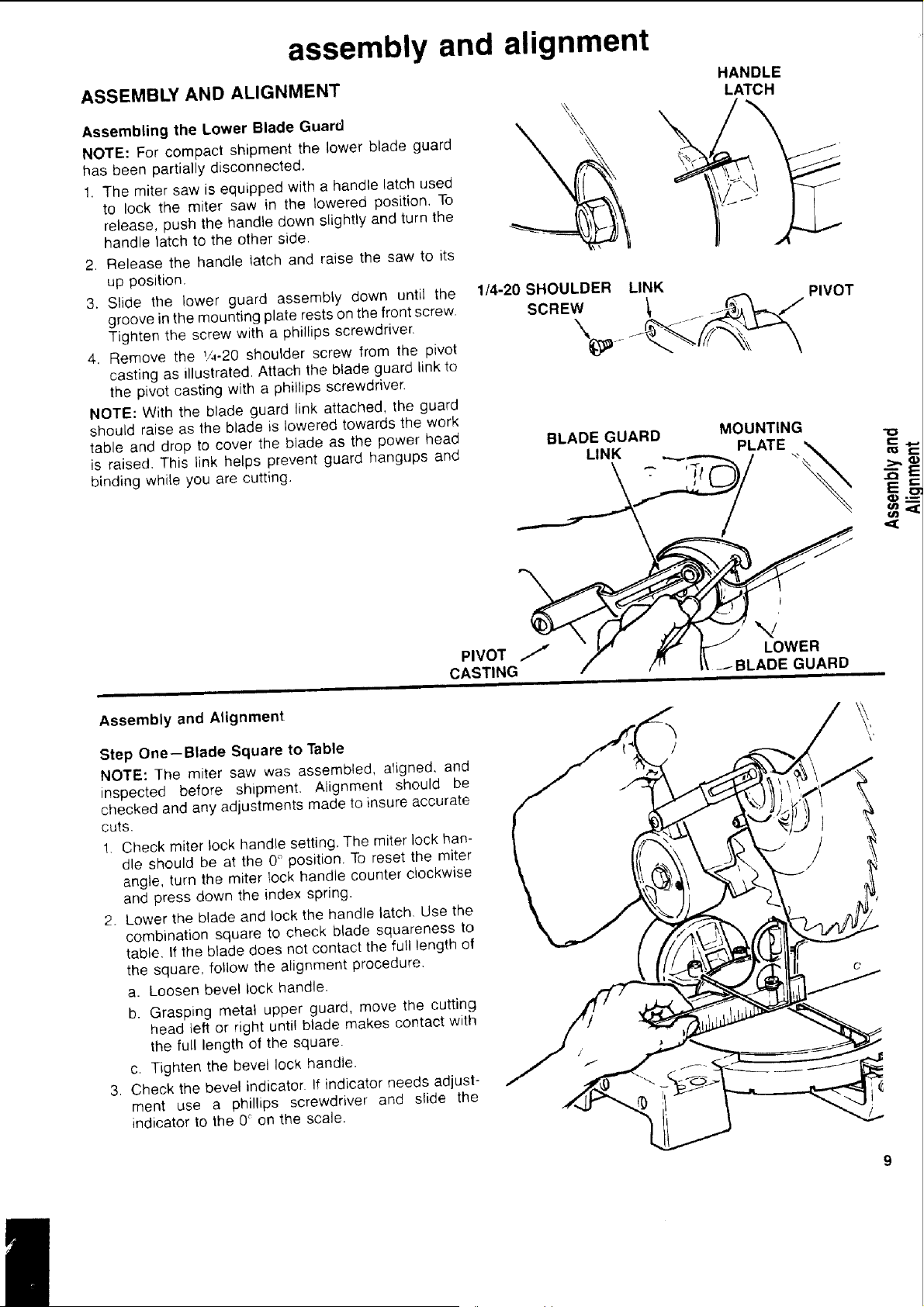

Assembling the Lower Blade Guard

NOTE: For compact shipment the lower blade guard

has been partially disconnected.

1. The miter saw is equipped with a handle latch used

to lock the miter saw in the lowered position. To

release, push the handle down slightly and turn the

handle latch to the other side.

2, Release the handle iatch and raise the saw to its

up position.

3. Slide the lower guard assembly down until the

groove in the mounting plate rests on the front screw.

Tighten the screw with a phillips screwdriver,

4. Remove the v4.20 shoulder screw from the pivot

casting as illustrated, Attach the blade guard link to

the pivot casting with a phillips screwdriver.

NOTE: With the blade guard link attached, the guard

should raise as the blade is lowered towards the work

table and drop to cover the blade as the power head

\

HANDLE

LATCH

1/4-20 SHOULDER LINK

SCRE_;_, ____ PIVOT

BLADE GUARD

MOUNTING

is raised. This link helps prevent guard hangups and LINK ,--.-._.--,._ PLATE -.-

.,vo. Y--" .ow .

CASTING f /71 _ JBLADE GUARD

Assembly and Alignment

Step One--Blade Square to Table

NOTE: The miter saw was assembled, aligned, and

inspected before shipment. Alignment should be

checked and any adjustments made to insure accurate

cuts.

1. Check miter lock handle setting, The miter lock han-

dle should be at the 0° position. To reset the miter

angle, turn the miter lock handle counter clockwise

and press down the index spring.

2. Lower the blade and lock the handle latch. Use the

combination square to check blade squareness to

table. If the blade does not contact the full length of

the square, follow the alignment procedure.

a. Loosen bevel lock handle.

b. Grasping metal upper guard, move the cutting

head left or right until blade makes contact with

the full length of the square.

c. Tighten the bevel IocX handle.

3, Check the bevel indicator. If indicator needs adjust-

ment use a phi/lips screwdriver and slide the

indicator to the 0° on the scale.

p.

8.'.'

Loading ...

Loading ...

Loading ...