Loading ...

Loading ...

Loading ...

this heater has been certified to be used with

polypropylene vent systems. A polypropylene to

PVC end connection is required. Optional wall

plates that fit the polypropylene venting are also

available.

Carefully inspect the entire venting system for any

signs of cracks or fractures, particularly at joints

between elbows and other fittings and straight runs

of vent pipe. Check system for signs of sagging or

other stresses in joints as a result of misalignment

of any components in the system. If any of these

conditions are found, they must be corrected in

accordance with the venting instructions in this

manual before completing installation and putting

the water heater into service.

The vent piping shall be connected to the blower

with the rubber coupling and secured with gear

clamps. The coupling and clamps are provided with

the heater.

Even though the flue gas temperature leaving the

blower is hot, some installations will have water

condense in the vent piping. If this occurs, then

adequate means of draining and disposing of the

condensate shall be made by the installer.

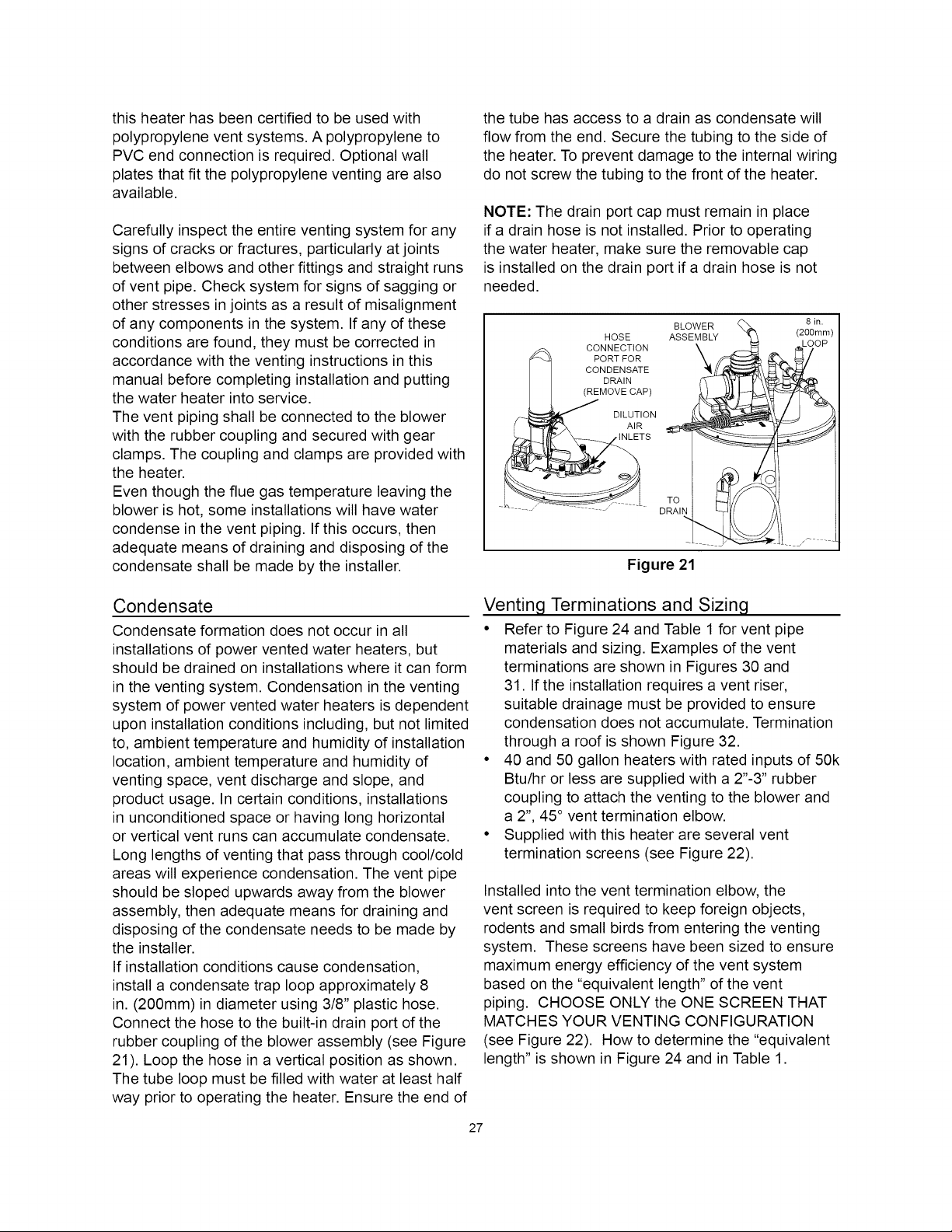

the tube has access to a drain as condensate will

flow from the end. Secure the tubing to the side of

the heater. To prevent damage to the internal wiring

do not screw the tubing to the front of the heater.

NOTE: The drain port cap must remain in place

if a drain hose is not installed. Prior to operating

the water heater, make sure the removable cap

is installed on the drain port if a drain hose is not

needed.

BLOWER (_

HOSE _E_Y

.... CONNECTION

_ ' PORT FOR

CONDENSATE

DRAIN

(REMOVE CAP)

/__ _ DILUTION

I _ AIR

__TS TO

DRAIN

Figure 21

8 in.

(200mm)

Condensate

Condensate formation does not occur in all

installations of power vented water heaters, but

should be drained on installations where it can form

in the venting system. Condensation in the venting

system of power vented water heaters is dependent

upon installation conditions including, but not limited

to, ambient temperature and humidity of installation

location, ambient temperature and humidity of

venting space, vent discharge and slope, and

product usage. In certain conditions, installations

in unconditioned space or having long horizontal

or vertical vent runs can accumulate condensate.

Long lengths of venting that pass through cool/cold

areas will experience condensation. The vent pipe

should be sloped upwards away from the blower

assembly, then adequate means for draining and

disposing of the condensate needs to be made by

the installer.

If installation conditions cause condensation,

install a condensate trap loop approximately 8

in. (200mm) in diameter using 3/8" plastic hose.

Connect the hose to the built-in drain port of the

rubber coupling of the blower assembly (see Figure

21). Loop the hose in a vertical position as shown.

The tube loop must be filled with water at least half

way prior to operating the heater. Ensure the end of

Venting Terminations and Sizing

• Refer to Figure 24 and Table 1 for vent pipe

materials and sizing. Examples of the vent

terminations are shown in Figures 30 and

31. If the installation requires a vent riser,

suitable drainage must be provided to ensure

condensation does not accumulate. Termination

through a roof is shown Figure 32.

• 40 and 50 gallon heaters with rated inputs of 50k

Btu/hr or less are supplied with a 2"-3" rubber

coupling to attach the venting to the blower and

a 2", 45 ° vent termination elbow.

• Supplied with this heater are several vent

termination screens (see Figure 22).

Installed into the vent termination elbow, the

vent screen is required to keep foreign objects,

rodents and small birds from entering the venting

system. These screens have been sized to ensure

maximum energy efficiency of the vent system

based on the "equivalent length" of the vent

piping. CHOOSE ONLY the ONE SCREEN THAT

MATCHES YOUR VENTING CONFIGURATION

(see Figure 22). How to determine the "equivalent

length" is shown in Figure 24 and in Table 1.

27

Loading ...

Loading ...

Loading ...