Loading ...

Loading ...

• Keep air filter clean. A dirty filter will reduce the air pressure

to the tool causing a reduction in power and efficiency.

• The air supply system must be able to provide air pressure

of 60 to 100 pounds per square inch at tool.

• All hoses and pipes in the air supply system must be clean

and free of moisture and foreign particles.

• Do not mount swivel connector in air supply line.

• The air pressure should be properly regulated.

• Different workpiece materials and different fastener lengths

will require different operating pressure.

° Be sure all connections in air supply system are sealed to

prevent air loss.

° Never connect a female quick-disconnect coupling to the

tool side of air line connection. A male, free-flow coupling

should be connected to the tool side of air line connection.

WARNING: The female coupling provides a seal preventing

loss of compressed air from compressor tank when discon-

nected from male coupling. If connected to tool side of air

supply, the female coupling could seal a compressed air

charge in the tool which could discharge if the tool trigger is

actuated.

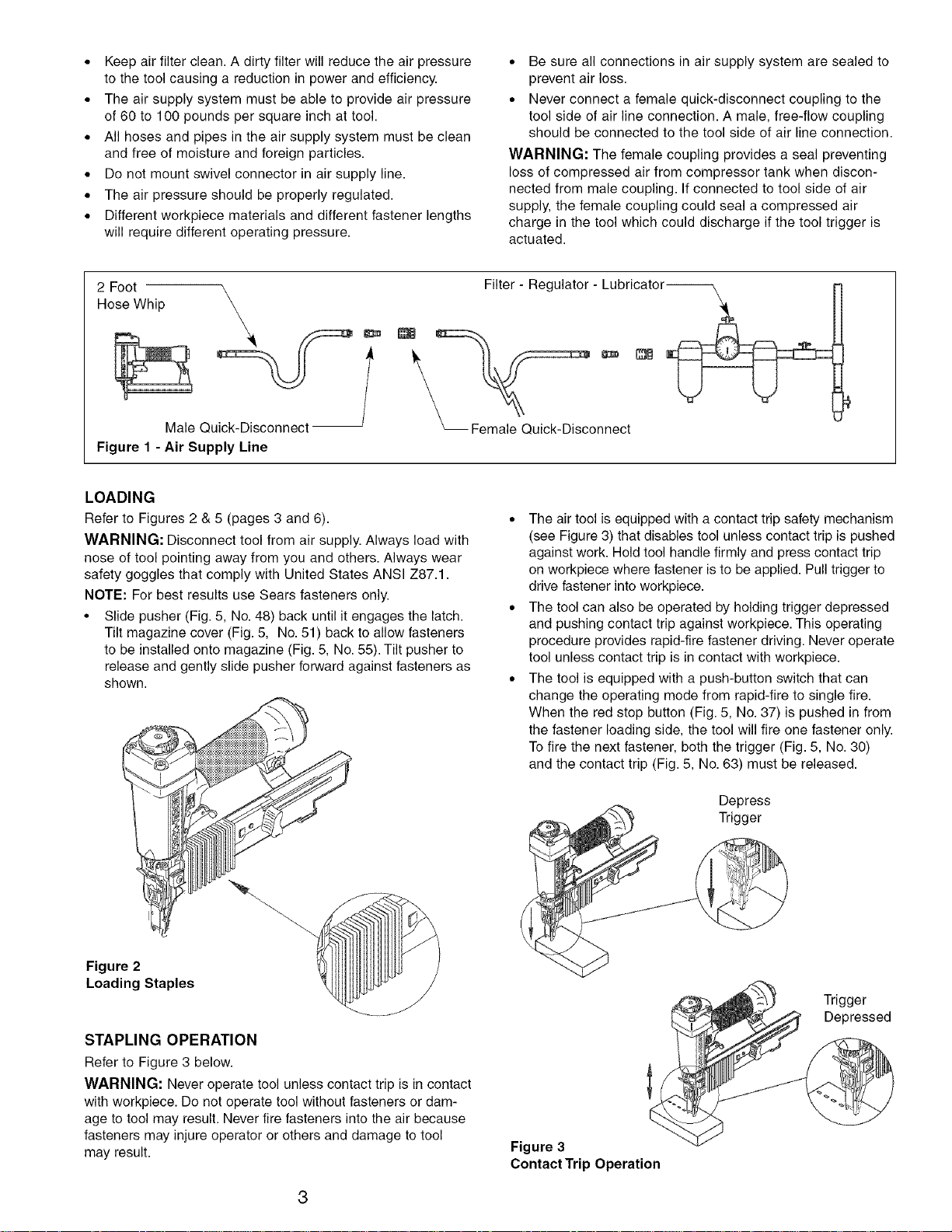

2 Foot

Hose Whip

Male Quick-Disconnect-

Figure 1 - Air Supply Line

Filter - Regulator - Lubricator_

LOADING

Refer to Figures 2 & 5 (pages 3 and 6).

WARNING: Disconnect tool from air supply. Always load with

nose of tool pointing away from you and others. Always wear

safety goggles that comply with United States ANSI Z87.1.

NOTE: For best results use Sears fasteners only.

• Slide pusher (Fig. 5, No. 48) back until it engages the latch.

Tilt magazine cover (Fig. 5, No. 51) back to allow fasteners

to be installed onto magazine (Fig. 5, No. 55). Tilt pusher to

release and gently slide pusher forward against fasteners as

shown.

° The air tool is equipped with a contact trip safety mechanism

(see Figure 3) that disables tool unless contact trip is pushed

against work. Hold tool handle firmly and press contact trip

on workpiece where fastener is to be applied. Pull trigger to

drive fastener into workpiece.

° The tool can also be operated by holding trigger depressed

and pushing contact trip against workpiece. This operating

procedure provides rapid-fire fastener driving. Never operate

tool unless contact trip is in contact with workpiece.

° The tool is equipped with a push-button switch that can

change the operating mode from rapid-fire to single fire.

When the red stop button (Fig. 5, No. 37) is pushed in from

the fastener loading side, the tool will fire one fastener only.

Tofire the next fastener, both the trigger (Fig. 5, No. 30)

and the contact trip (Fig. 5, No. 63) must be released.

Depress

Trigger

Figure 2

Loading Staples

STAPLING OPERATION

Refer to Figure 3 below.

WARNING: Never operate tool unless contact trip is in contact

with workpiece. Do not operate tool without fasteners or dam-

age to tool may result. Never fire fasteners into the air because

fasteners may injure operator or others and damage to tool

may result.

Figure 3

Contact Trip Operation

Trigger

Depressed

Loading ...

Loading ...

Loading ...