Loading ...

Loading ...

3

Operating Instructions and Parts Manual 24338

4/18

2018 OEMTOOLS

™

100A BATTERY TESTER

WARNING: ALWAYS wear eye protection and protective

clothing when working with or in the vicinity of a lead-acid

battery. It is recommended that you have fresh water, soap

and baking soda in the immediate vicinity of the workspace.

If battery acid contacts your eyes, skin or clothing,

wash immediately with water and soap; contact medical

professionals. Neutralize any lead acid spills with baking

soda prior to clean-up.

TESTING PREPARATION INSTRUCTIONS

WARNING: To prevent overheating, allow the tester to

cool for 5 minutes between tests.

NOTE: This product does not require assembly.

NOTE: You may notice a slight burning smell during the first

few uses of this product. This is normal and will fade.

1. Turn the ignition OFF. Turn OFF all accessories that may

place load on battery.

2. Clean the battery terminals.

3. Clip the Red Clamp to the Positive (+) battery terminal.

4. Clip the Black Clamp to the Negative (-) battery terminal.

6V BATTERY TESTING INSTRUCTIONS

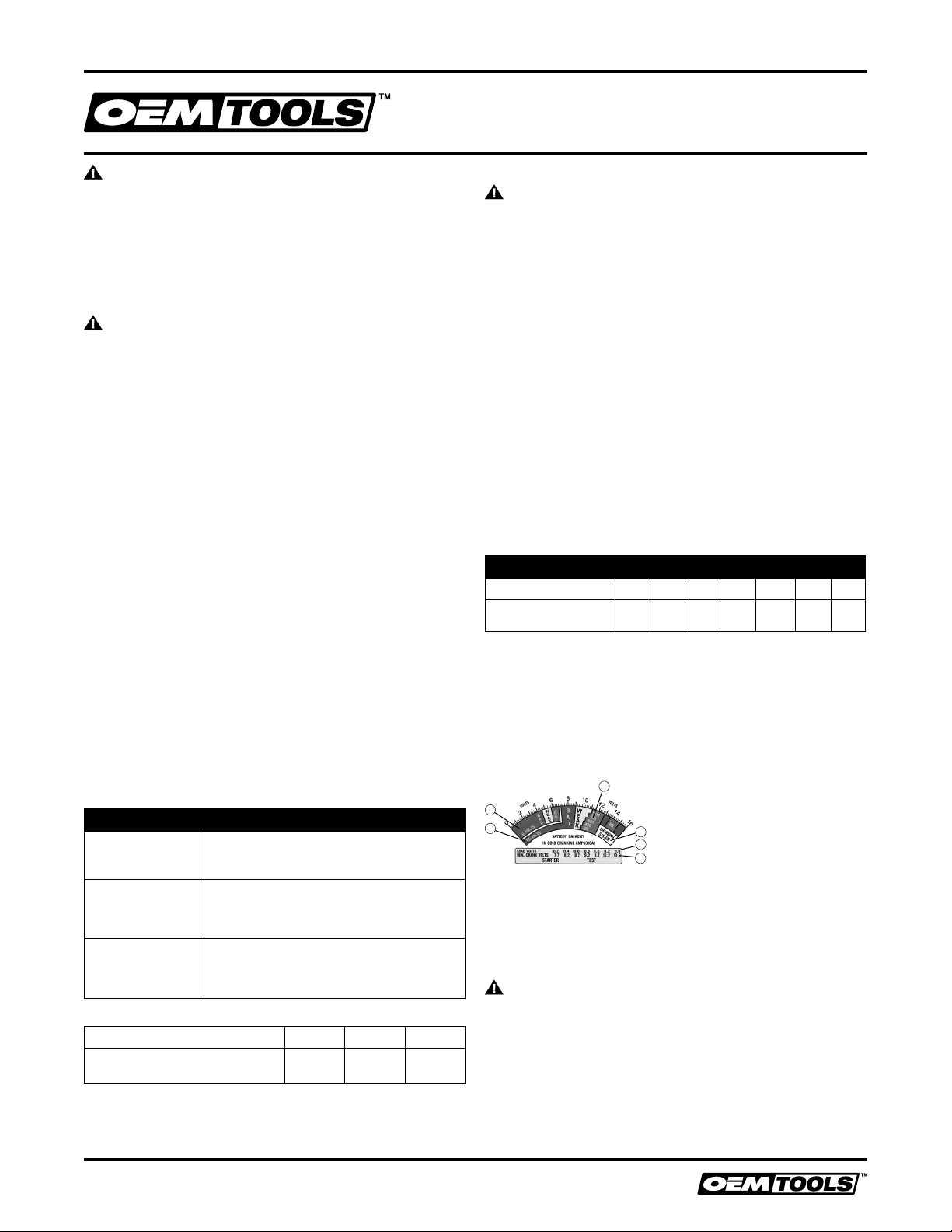

1. After the proper preparation steps have been taken, read

the meter and confirm battery voltage is in the green “OK”

area. See image of meter below.

2. Press and hold the load switch ON for a maximum of 10

seconds. Read the meter while the load switch is ON. The

needle should remain in the green area.

12V BATTERY TESTING INSTRUCTIONS

1. Check the Cold Cranking Amps (CCA) of the battery being

tested.

2. Connect the tester as described in the Testing Preparation

Instructions.

3. Press and hold the load switch ON for a maximum of 10

seconds. Read the meter while the load switch is ON.

Refer to Battery Analysis Table in this manual or on the

back of the unit.

BATTERY ANALYSIS TABLE

TESTING THE CHARGING SYSTEM

WARNING: Be cautious of moving parts while the

engine is running.

1. Connect the tester as described in the Testing Preparation

Instructions.

2. Turn off all lights and electrical accessories. Run the

engine at 1,200 to 1,500 RPM.

NOTE: DO NOT press the load switch.

3. Read the meter voltage. Meter should be within the green

“OK” band.

4. Turn on the high beams and turn the A/C blower on high.

Meter should remain within the green “OK” band.

5. If the meter does not read within the green “OK” band, the

charging system is not operating correctly.

STARTER MOTOR TEST

NOTE: The engine must be at normal operating temperature

to perform this test.

1. Perform the battery load test; if the battery is in weak or

bad condition, this test cannot be performed. Record the

exact voltage of the load test.

2. Determine the minimum cranking voltage using the voltage

recorded in step 1.

Starter Test Voltage

LOAD VOLTAGE 10.2 10.4 10.6 10.8 11.0 11.2 11.4

MINIMUM CRANKING

VOLTAGE

7.7 8.2 8.7 9.2 9.7 10.2 10.6

NOTE: If possible, disable the vehicle’s ignition system. The

starter motor test is most accurate if the starter cranks for

2-5 seconds.

3. Crank the engine and record the voltage reading.

4. If the cranking voltage is below the minimum cranking

shown in the Start Test Voltage Table, the starter current

draw is excessive. This may be due to bad connections or

a failing starter motor.

METER

PRODUCT STORAGE

Always store the battery tester in a well-protected area where

it will not be exposed to inclement weather, corrosive vapors,

abrasive dust, fire, or any other harmful elements.

PRODUCT MAINTENANCE

WARNING: DO NOT attempt to repair or disassemble

the tester. Contact customer service or a qualified service

professional.

1. Disconnect from battery and allow the unit to cool.

2. Use a clean, dry cloth to wipe the outer surfaces of the

battery tester clean.

DISPOSAL

At the end of the useful life of the OEMTOOLS

™

24338 100A

Battery Tester, dispose of the components in accordance

with all federal, state and local regulations.

Indication Battery Condition

GREEN OK - Battery may or may not be fully charged.

Check the specific gravity of the battery to

determine charge level, recharge if necessary.

YELLOW / RED

(STEADY NEEDLE)

WEAK - Battery capacity is not satisfactory.

Check the specific gravity of the battery. If full

charge cannot be reached after attempting

recharge, the battery should be replaced.

YELLOW / RED

(FALLING NEEDLE)

WEAK OR DEFECTIVE - Release the load

switch. If immediate voltage recovery (to

12V or above) is noted, the battery may be

defective. Check the specific gravity.

BATTERY TEMPERATURE +20°F 0°F -20°F

DECREASE BATTERY RATING

BY (CRANKING AMPS)

200 400 600

TEMPERATURE COMPENSATION

1. Range for 6 Volt battery load testing

2. Range for 12 Volt battery load testing

3. Cold cranking amps range

4. Charging system test range

5. Voltage scale

6. Starter voltage test table

1

3

5

4

6

2

Loading ...