Loading ...

Loading ...

Loading ...

Super Free Match Series

11

6.4 Connection of Refrigerant Pipes

CAUTION

1) Conform to the following principles during pipe connection: Outdoor unit shall be installed close to the

indoor unit, hence to minimize the length and bends of connection pipes; the height gap of outdoor unit

and indoor units should be as small as possible; the radius of curvature should be as large as possible.

2) The brazing operation must be strictly in accordance with the process requirements. Rosin joint or pin

hole is not allowed.

3) During the installation, do not damage the pipeline. The pipeline’s radius of bending must be over than

200mm(8inch). The pipes cannot repeatedly be bent or straightened. Otherwise it will get harden and

crack. Do not bend or straight the pipes for more than 3 times at the same position.

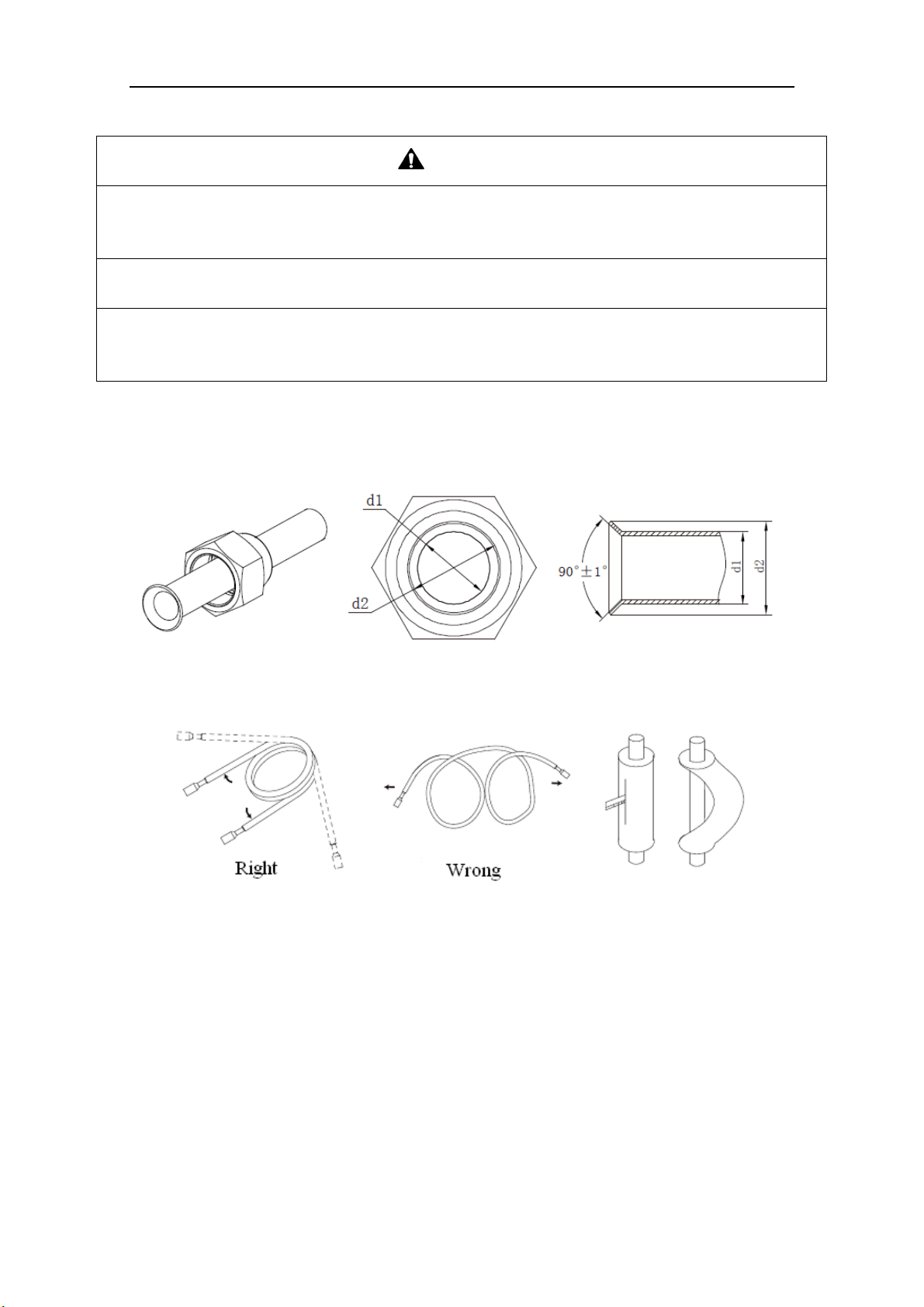

1) The process of flaring

① Using the tube cutter to cut the connecting pipe in the appropriate place and remove the burrs.

② Install the nut before the flaring operation.

③ Check the flared portion, whether there is fractured or not.

Fig. 12

2) Precaution for elbow operation

① The elbow operation could be done by hands. Be careful and do not damage the pipe.

Fig. 13

② If the thermal insulation of the refrigerant pipe is not removed, please do not bend the pipe.

Otherwise, it maybe leads the pipe to crack. It is better to make an incision with a knife in the

thermal insulation and removes it. After elbow operation is finished, recover the thermal

insulation with binding band.

3) The process of install refrigerant pipes

① Remove the screw caps from the pipes.

② Align the flared end of copper tube with the center of pipe joint. Tighten the nuts by hands. (If

the flared end of copper tube and the center of pipe joint are not in coaxial, it is hard to tighten

the nuts by hands, please do not tighten it with spanners, because the screw thread may be

broken by force).

③ Tighten the flaring nuts with torque wrench until you hear a “click”. (The spanner and torque

Loading ...

Loading ...

Loading ...