Loading ...

Loading ...

Loading ...

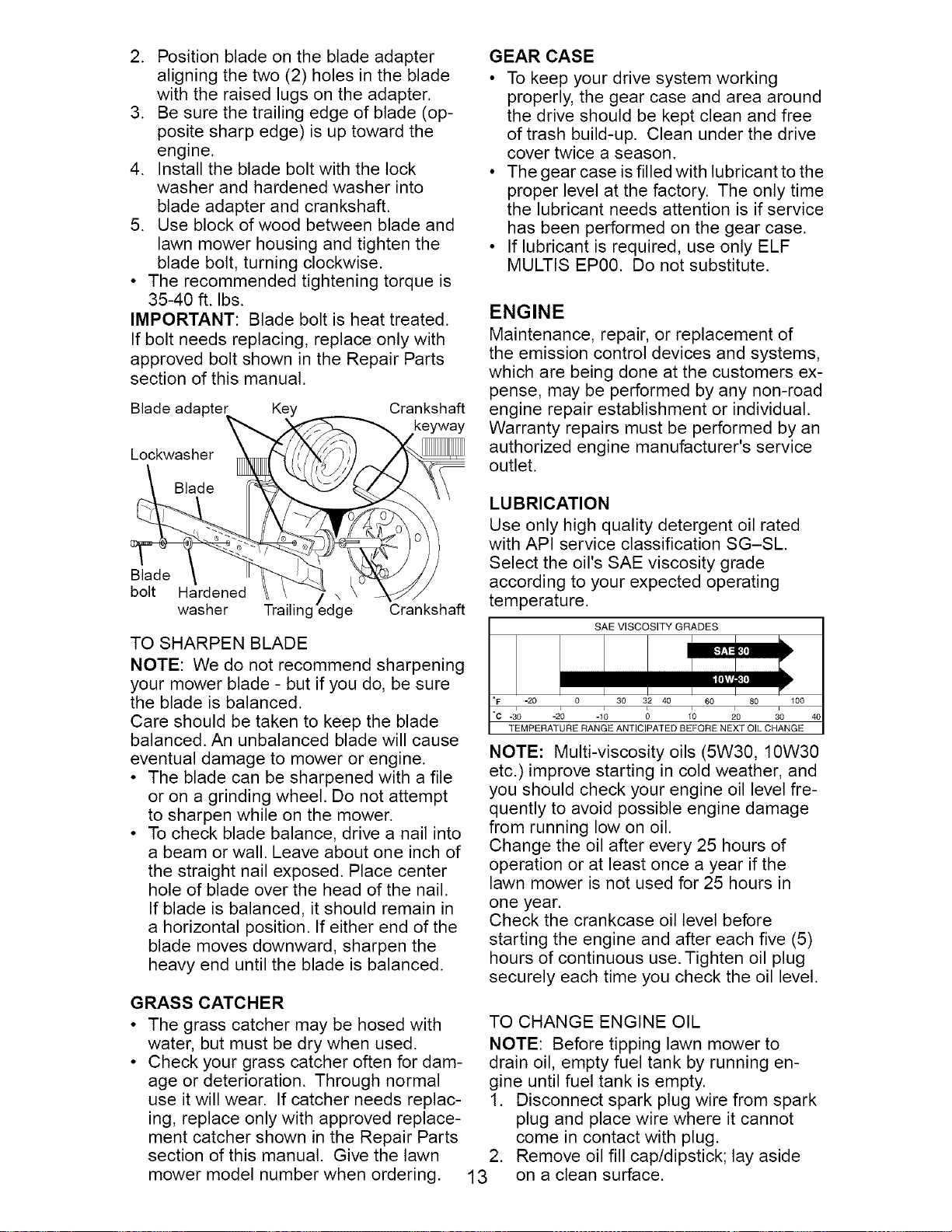

2. Position blade on the blade adapter

aligning the two (2) holes in the blade

with the raised lugs on the adapter.

3. Be sure the trailing edge of blade (op-

posite sharp edge) is up toward the

engine.

4. Install the blade bolt with the lock

washer and hardened washer into

blade adapter and crankshaft.

5. Use block of wood between blade and

lawn mower housing and tighten the

blade bolt, turning clockwise.

• The recommended tightening torque is

35-40 ft. Ibs.

IMPORTANT: Blade bolt is heat treated.

If bolt needs replacing, replace only with

approved bolt shown in the Repair Parts

section of this manual.

Blade adapter Key Crankshaft

Lockwasher

Blade

Blade

bolt Hardened

/\

washer Trailing edge Crankshaft

TO SHARPEN BLADE

NOTE: We do not recommend sharpening

your mower blade - but if you do, be sure

the blade is balanced.

Care should be taken to keep the blade

balanced. An unbalanced blade will cause

eventual damage to mower or engine.

• The blade can be sharpened with a file

or on a grinding wheel. Do not attempt

to sharpen while on the mower.

• To check blade balance, drive a nail into

a beam or wall. Leave about one inch of

the straight nail exposed. Place center

hole of blade over the head of the nail.

If blade is balanced, it should remain in

a horizontal position. If either end of the

blade moves downward, sharpen the

heavy end until the blade is balanced.

GRASS CATCHER

• The grass catcher may be hosed with

water, but must be dry when used.

• Check your grass catcher often for dam-

age or deterioration. Through normal

use it will wear. If catcher needs replac-

ing, replace only with approved replace-

ment catcher shown in the Repair Parts

section of this manual. Give the lawn

mower model number when ordering.

GEAR CASE

• To keep your drive system working

properly, the gear case and area around

the drive should be kept clean and free

of trash build-up. Clean under the drive

cover twice a season.

• The gear case is filled with lubricant to the

proper level at the factory. The only time

the lubricant needs attention is if service

has been performed on the gear case.

• If lubricant is required, use only ELF

MULTIS EP00. Do not substitute.

ENGINE

Maintenance, repair, or replacement of

the emission control devices and systems,

which are being done at the customers ex-

pense, may be performed by any non-road

engine repair establishment or individual.

Warranty repairs must be performed by an

authorized engine manufacturer's service

outlet.

LUBRICATION

Use only high quality detergent oil rated

with API service classification SG-SL

Select the oil's SAE viscosity grade

according to your expected operating

temperature.

SAE VISCOSITY GRADES

°F -20 0 30 32 40 60 80 100

°c -3o -2; -,; ; ;0 _0 _0

TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

NOTE: Multi-viscosity oils (5W30, 10W30

etc.) improve starting in cold weather, and

you should check your engine oil level fre-

quently to avoid possible engine damage

from running low on oil.

Change the oil after every 25 hours of

operation or at least once a year if the

lawn mower is not used for 25 hours in

one year.

Check the crankcase oil level before

starting the engine and after each five (5)

hours of continuous use. Tighten oil plug

securely each time you check the oil level.

TO CHANGE ENGINE OIL

NOTE: Before tipping lawn mower to

drain oil, empty fuel tank by running en-

gine until fuel tank is empty.

1. Disconnect spark plug wire from spark

plug and place wire where it cannot

come in contact with plug.

2. Remove oil fill cap/dipstick; lay aside

13 on a clean surface.

Loading ...

Loading ...

Loading ...