Loading ...

Loading ...

Loading ...

English – 9

General

This section describes the machine's safety equipment,

its purpose, and how checks and maintenance should be

carried out to ensure that it operates correctly.

!

WARNING! Never use a machine that

has faulty safety equipment! If your

machine fails any checks contact your

service agent to get it repaired.

Prevent unintentional starting by

removing the ignition cable from the

spark plug.

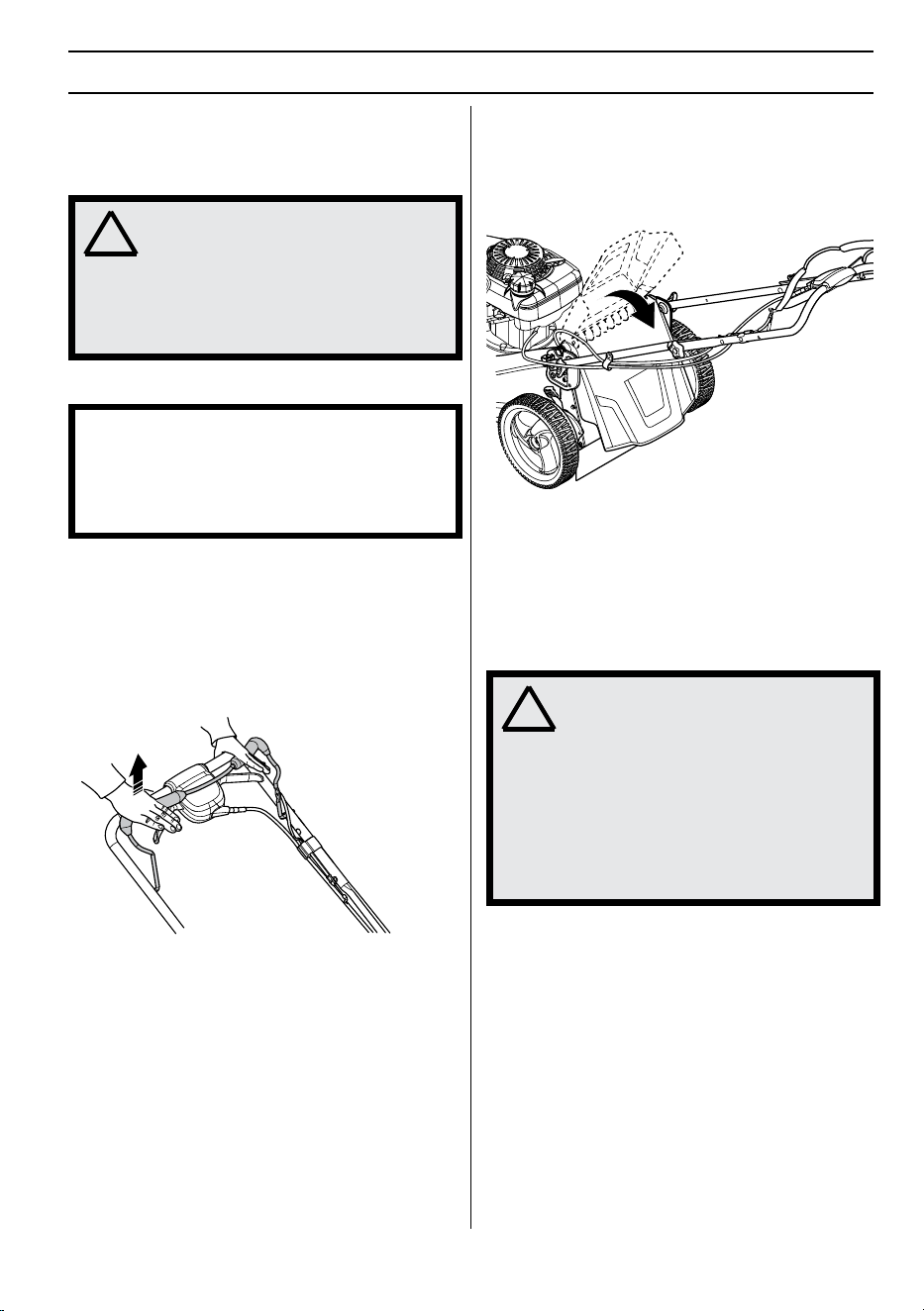

Operator presence control bar

IMPORTANT! Federal regulations require an engine

control to be installed on this lawn mower in order to

minimize the risk of blade contact injury. Do not under

any circumstances attempt to defeat the function of the

operator control. The blade turns when the engine is

running.

The engine brake is designed to stop the engine. When

the grip on the operator presence control bar is released

the engine should stop.

Checking the operator presence control bar

• Start the engine and then release the operator

presence control bar. The engine should stop.

Rear deflector

The rear deflector, attached between the rear wheels of

your mower, is provided to minimize the possibility that

objects will be thrown out of the rear of the mower into the

operator’s mowing position.

Inspecting the rear deflector

• Make sure the rear deflector is not damaged and that

there are no visible defects such as cracks, or broken

springs that force the door closed. Replace the

deflector or springs if damaged.

Muffler

!

WARNING! Never use a machine without

a muffler, or with a faulty muffler. A

damaged muffler may substantially

increase the noise level and the fire

hazard. Keep fire fighting equipment

handy.

The muffler gets very hot during and

after use. This also applies during idling.

Be aware of the fire hazard, especially

when working near flammable

substances and/or vapours.

The muffler is designed to keep noise levels to a minimum

and to direct exhaust fumes away from the user.

Inspecting the muffler

• Check regularly that the muffler is complete and

secured correctly.

MACHINE´S SAFETY EQUIPMENT

Loading ...

Loading ...

Loading ...