Loading ...

Loading ...

Loading ...

11

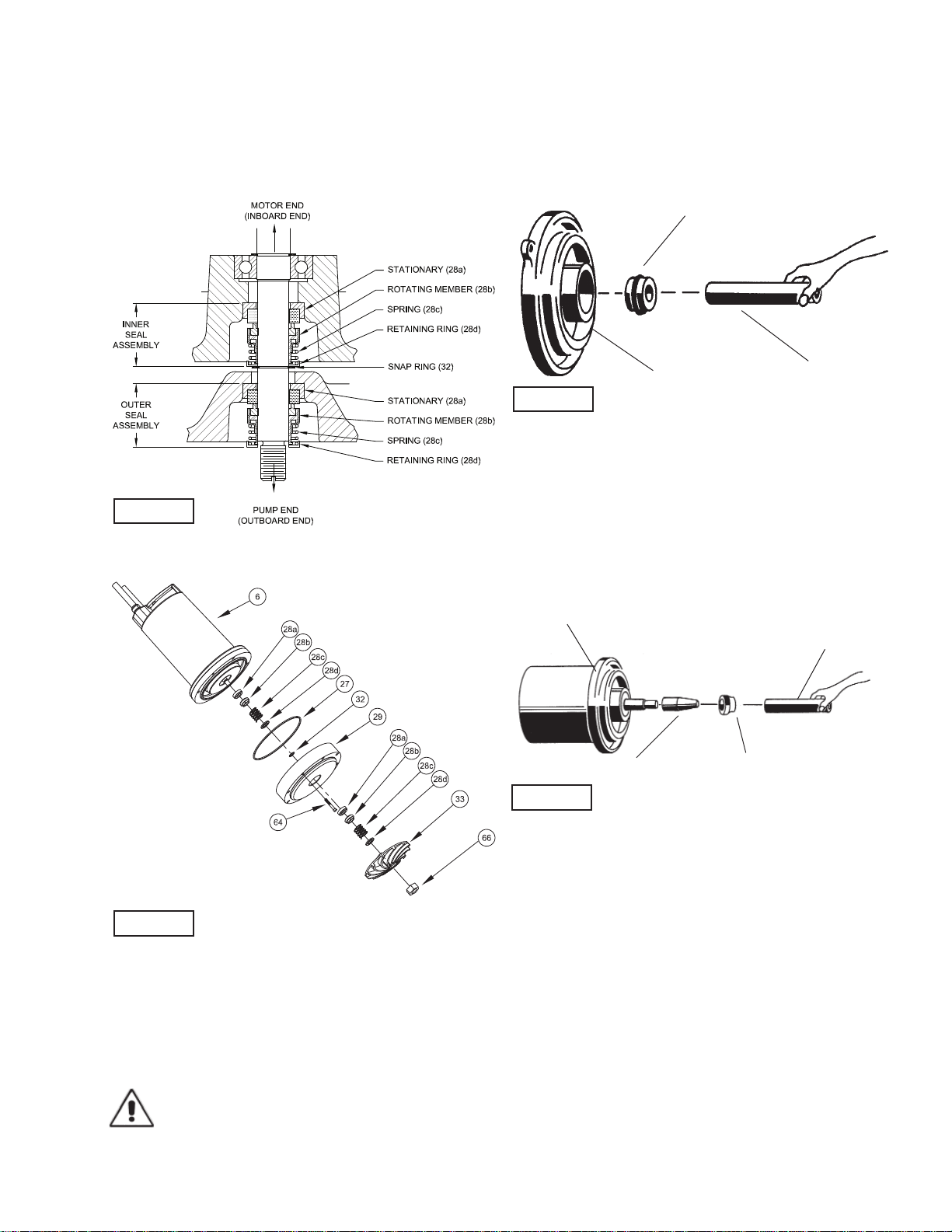

FIGURE 8

Inner Seal (DS Units Only)- To expose inner shaft seal

(28) for examination, remove outer seal as outlined above.

Remove socket head cap screws (64). Lift outer seal plate (29)

and square-ring (27) from inner seal plate (5), See Figures 6 &

7. If further repair is required, remove snap ring (32), retaining

ring (28d), spring (28c) and rotating member (28b) from shaft.

Examine as outlined in outer seal paragraph. If replacing seal,

remove stationary (28a) by prying out with fl at screwdriver.

F-3.2) Reassembly:

Inner Seal (DS Units Only)- Clean and oil seal cavities in seal

plates (5, 29). Lightly oil (DO NOT use grease) outer surface

of stationary member (28a). Press stationary member (28a)

fi rmly into inner seal plate (5), using a seal pusher (see parts

list - seal tool kit). Nothing but the seal pusher is to come in

contact with seal face (see Figure 8).

Important ! - DO NOT hammer on the seal pusher-

it will damage the seal face.

Make sure the stationary member is in straight. Slide a bullet

(see parts list - seal tool kit) over motor shaft. Lightly oil (DO NOT

use grease) shaft, bullet and inner surface of bellows on rotating

member (28b), see Figure 9. With lapped surface of rotating

member (28b) facing inward toward stationary member, slide

rotating member over bullet and onto shaft, using seal pusher,

until lapped faces of (28a) and (28b) are together (see Figure 8).

It is extremely important to keep seal faces clean during

assembly. Dirt particles lodged between these faces will cause

the seal to leak. Place spring (28c) over shaft and in place on

rotating member (28b), making sure it is seated on retainer and

not cocked or resting on bellows tail. Slide retaining ring (28d)

over shaft and let rest on spring (28c). Replace snap ring (32)

in groove of shaft. Set square-ring (27) in groove on outer seal

plate (29) and place outer seal plate (29) onto inner seal plate

(5). Replace socket head cap screws (64) and torque to 60 in-lbs.

Outer Seal (All Units) - Press stationary member (28a) fi rmly

into outer seal plate (5, or 29 on DS Units) as described

above. Slide rotating member (28b) onto stationary member

using seal pusher as described above. Place spring (28c) and

retaining ring (28d) onto rotating member (28b). Assemble

impeller and volute as outlined in paragraph F-2.2. Replace oil

as outlined in paragraph F-1.4.

F-4) Motor and Bearing Service:

F-4.1) Disassembly and Inspection:

To examine or replace the motor (7), capacitor (9, single

phase units), controls (56, optional), and bearing (25), drain

oil from motor as outlined in paragraph F-1.1. Disassemble

volute and impeller as outlined in paragraph F-2.1 and

disassemble shaft seal as outlined in paragraph F-3.1.

FIGURE 7

FIGURE 6

Rotating Member

(28B)

Motor & Seal Plate

Bullet

Seal Pusher

FIGURE 9

Seal Pusher

Seal Plate (5) for L series

and (29) for DS series

Stationary Member

(28A) Polished Face Out

Loading ...

Loading ...

Loading ...