Loading ...

Loading ...

Loading ...

15

ENGLISH

When smoothest cuts are desired for molding and other

precision work, a sharp (60 tooth carbide tip) blade and a

slower, even cutting rate will produce the desiredresults.

Ensure that the material does not move or creep while

cutting; clamp it securely in place. Always let the blade

come to a full stop before raisingarm.

If small fibers of wood still split out at the rear of the

workpiece, stick a piece of masking tape on the wood where

the cut will be made. Saw through the tape and carefully

remove tape whenfinished.

For varied cutting applications, refer to the list of

recommended saw blades for your saw and select the

one that best fits your needs. Refer to Saw Blades under

OptionalAccessories.

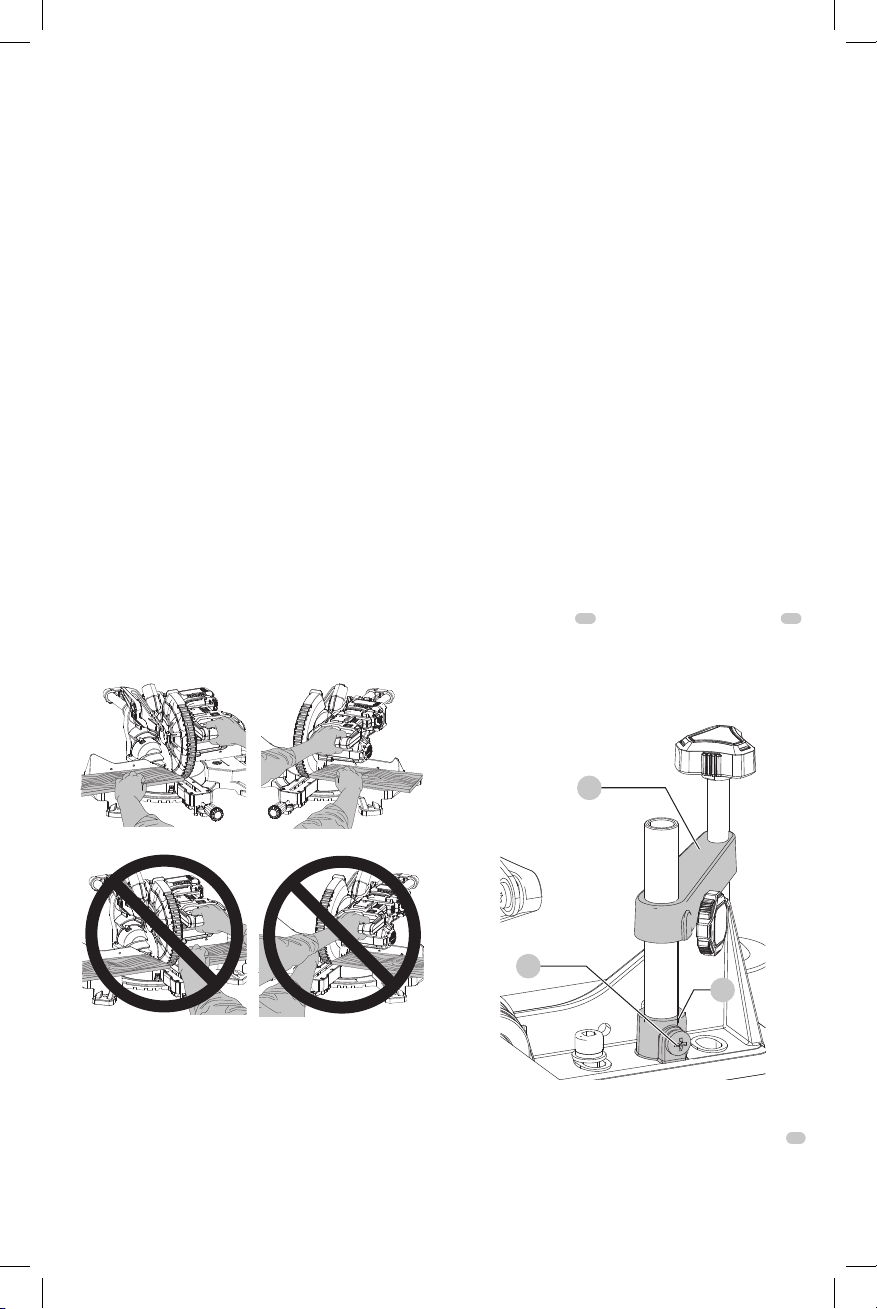

Body and Hand Position (Fig. N1–N4)

Proper positioning of your body and hands when operating

the miter saw will make cutting easier, more accurate and

safer. Never place hands near cutting area. Place hands no

closer than 4" (100 mm) from the blade. Hold the workpiece

tightly to the table and the fence when cutting. Keep hands

in position until the trigger has been released and the

blade has completely stopped. ALWAYS MAKE DRY RUNS

(UNPOWERED) BEFORE FINISH CUTS SO THAT YOU CAN

CHECK THE PATH OF THE BLADE. DO NOT CROSS HANDS, AS

SHOWN IN FiguresN3 and N4.

Keep both feet firmly on the floor and maintain proper

balance. As you move the miter arm left and right, follow

it and stand slightly to the side of the saw blade. Sight

through the guard louvers when following a pencilline.

Fig. N1

Fig. N2

Fig. N3

Fig. N4

Clamping the Workpiece

WARNING: To reduce the risk of serious personal

injury, turn tool off and remove the battery pack

before transporting, making any adjustments or

removing/installing attachments or accessories.

An accidental start-up can causeinjury.

WARNING: A workpiece that is clamped, balanced

and secure before a cut may become unbalanced

after a cut is completed. An unbalanced load may tip

the saw or anything the saw is attached to, such as

a table or workbench. When making a cut that may

become unbalanced, properly support the workpiece

and ensure the saw is firmly bolted to a stable surface.

Personal injury mayoccur.

WARNING: The clamp foot must remain clamped

above the base of the saw whenever the clamp is

used. Always clamp the workpiece to the base of the

saw – not to any other part of the work area. Ensure

the clamp foot is not clamped on the edge of the base

of thesaw.

WARNING: Always use a work clamp to maintain

control and reduce the risk of workpiece damage and

personal injury, if your hands are required to be within

4" (100 mm) of the blade during thecut.

If you cannot secure the workpiece on the table and against

the fence by hand (irregular shape, etc.), or your hand

would be less than 4" (100 mm) from the blade, a clamp or

other fixture must beused.

Use the material clamp provided with your saw. To purchase

a material clamp, contact your local retailer or servicecenter.

Other aids such as spring clamps, bar clamps or C-clamps

may be appropriate for certain sizes and shapes of material.

Use care in selecting and placing these clamps. Take time to

make a dry run before making thecut.

To Install Clamp (Fig. A, O)

1. Insert the clamp

43

into the clamp mounting hole

17

behind the fence. The clamp should be facing toward

the back of the miter saw. The groove on the clamp rod

should be fully inserted into the base. Ensure this groove

is fully inserted into the base of the miter saw. If the

groove is visible, the clamp will not besecure.

Fig. O

17

43

46

2. Rotate the clamp 180º toward the front of the mitersaw.

3. Loosen the knob to adjust the clamp up or down, then

use the fine adjust knob and tighten the fence screw

46

to firmly clamp theworkpiece.

NOTE: Place the clamp on the opposite side of the base

when beveling. ALWAYS MAKE DRY RUNS (UNPOWERED)

Loading ...

Loading ...

Loading ...