Loading ...

Loading ...

Loading ...

EX08DT and EX11DT Installation and Operation Manual 25

Instructions:

Natural Gas

EX08DT Vent Lengths: 0 ft. (0 m) (A1-A4)

EX11DT Vent Lengths:

Short Vent Lengths: 0 - 7 ft. (2 m) + 1 elbow (A1 - A4)

Long Vent Lengths: 7 ft. (2 m) + 1 elbow - 13 ft. (4 m) +

3 elbows (A5 - A8)

Propane Gas

EX08DT Vent Lengths: 0 ft. (0 m) (L1-L4)

EX11DT Vent Lengths:

Short Vent Lengths: 0 - 7 ft. (2 m) + 1 elbow (L1 - L4)

Long Vent Lengths: 7 ft. (2 m) + 1 elbow - 13 ft. (4 m)

+ 3 elbows (L5 - L8)

Altitude

0-2,000 ft

0-610 m

2,001-5,400 ft

611-1,646 m

5,401-7,800 ft

1,647-2,377 m

7,801-10,200 ft

2,378-3,109 m

0-2,000 ft

0-610 m

2,001-5,400 ft

611-1,646 m

5,401-7,800 ft

1,647-2,377 m

7,801-10,200 ft

2,378-3,109 m

Manifold test

pressure - W.C.

Low

0.58 in.

(15 mm)

0.62 in.

(16 mm)

0.70 in.

(18 mm)

0.78 in.

(20 mm)

0.86 in.

(22 mm)

0.92 in.

(24 mm)

1.04 in.

(27 mm)

1.16 in.

(29 mm)

Manifold test

pressure - W.C.

High

3.4 in.

(86 mm)

3.6 in.

(92 mm)

4.1 in.

(103 mm)

3.2 in.

(82 mm)

5.8 in.

(147 mm)

6.2 in.

(158 mm)

7.0 in.

(177 mm)

5.5 in.

(140 mm)

EX11DT

Manifold test

pressure - W.C.

Low

0.60 in.

(15 mm)

0.64 in.

(16 mm)

0.72 in.

(19 mm)

0.80 in.

(20 mm)

1.06 in.

(27 mm)

1.16 in.

(29 mm)

1.28 in.

(33 mm)

1.41 in.

(36 mm)

Manifold test

pressure - W.C.

High

2.2 in.

(56 mm)

1.9 in.

(49 mm)

1.7 in.

(44 mm)

1.6 in.

(40 mm)

3.8 in.

(95 mm)

3.3 in.

(84 mm)

3.0 in.

(75 mm)

2.7 in.

(69 mm)

EX08DT

Code A1 / A5 A2 / A6 A3 / A7 A4 / A8 L1 / L5 L2 / L6 L3 / L7 L4 / L8

1. Turn off the gas and the power

supply.

2. Remove the 5 screws that hold the

louver assembly and front panel.

Lift the panel straight up and then

remove it.

3. Remove two pressure point screws

(1/8 NPT tap) with 3/16 Allen

wrench. Install two 1/8 in. barb

fittings (field-supplied). Attach the

manometer to both pressure points.

Both pressure points must be used

in order to measure the differential

pressure. Ensure that the

manometer is properly calibrated.

4. Turn on the gas and power supply

to the furnace.

5. Ensure the "Set Back" feature has

been deactivated. ("Set Back"

feature is active by default.)

6. With the unit in the Off position,

press the Test Switch at the top,

right of PC board until it beeps.

7. Select the correct code for gas

type, altitude, and vent length on

the LED display using ▲ and ▼

buttons. Refer to the table below.

Table 8: Gas Pressure

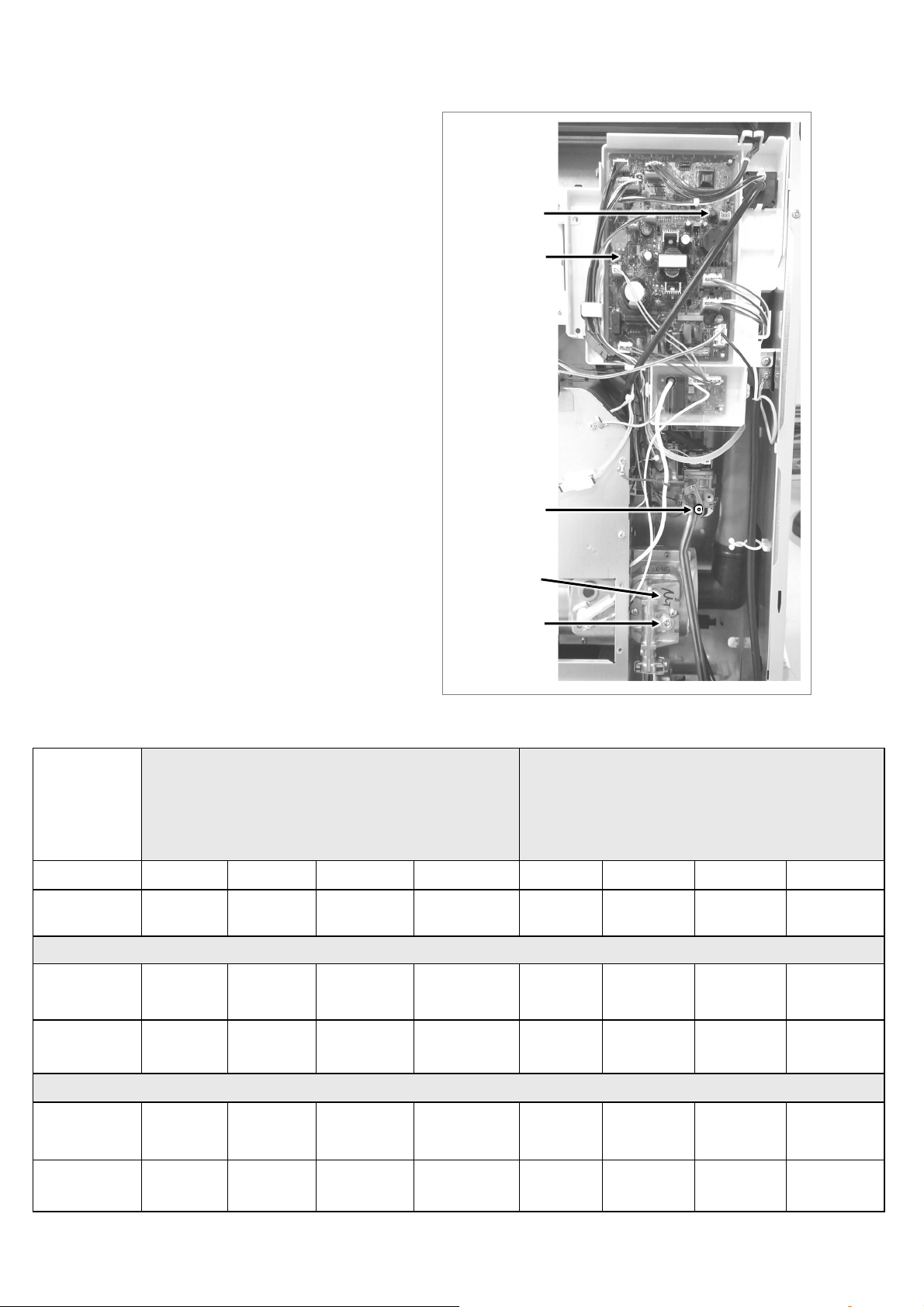

Figure 28

Pressure

Point

(Positive)

Pressure

Point

(Negative)

Nozzle

Manifold

Test

Switch

PC

Board

Loading ...

Loading ...

Loading ...