Loading ...

Loading ...

Loading ...

chokelevertotheOFFCHOKEposi-

tion.Allowtheunittorunfor30more

secondsattheOFFCHOKEposition

beforesqueezingandreleasingthe

throttletriggertoreleasethethrottle

lock.NOTE:Ifenginedieswiththe

chokeleverintheOFFCHOKEposi-

tion,movethechokelevertothe

HALFCHOKEpositionandpullthe

ropeuntilengineruns,butnomore

than6pulls.

STARTING A WARM ENGINE

1. Move the ON/OFF switch to the ON

position.

2. Slowly press the primer bulb 6

times.

3. Move the choke lever to the HALF

CHOKE position.

4. Engage the throttle lock as directed

in STARTING A COLD ENGINE.

NOTE: Keep the throttle lock engaged

until the engine starts.

5. Pull starter rope sharply until engine

runs, but no more than 5 pulls.

6. Allow the engine to run 10 seconds,

then move choke lever to the OFF

CHOKE position.

7. Release the throttle lock by squeez-

ing and releasing the throttle trigger.

NOTE: If engine has not started, pull

starter rope 5 more pulls. If engine still

does not run, it is probably flooded. Pro-

ceed to STARTING A FLOODED ENGINE.

STARTING A FLOODED ENGINE

Flooded engines can be started by

placing the ON/OFF switch in the ON

position and the choke lever in the OFF

CHOKE position and engaging the

throttle lock as directed in the START-

ING A COLD ENGINE section; then, pull

the rope to clear the engine of excess

fuel. Starting could require pulling the

starter rope many times depending on

how badly the unit is flooded.

If the unit still doesn't start, refer to the

TROUBLESHOOTING TABLE or call

1-800-235-5878.

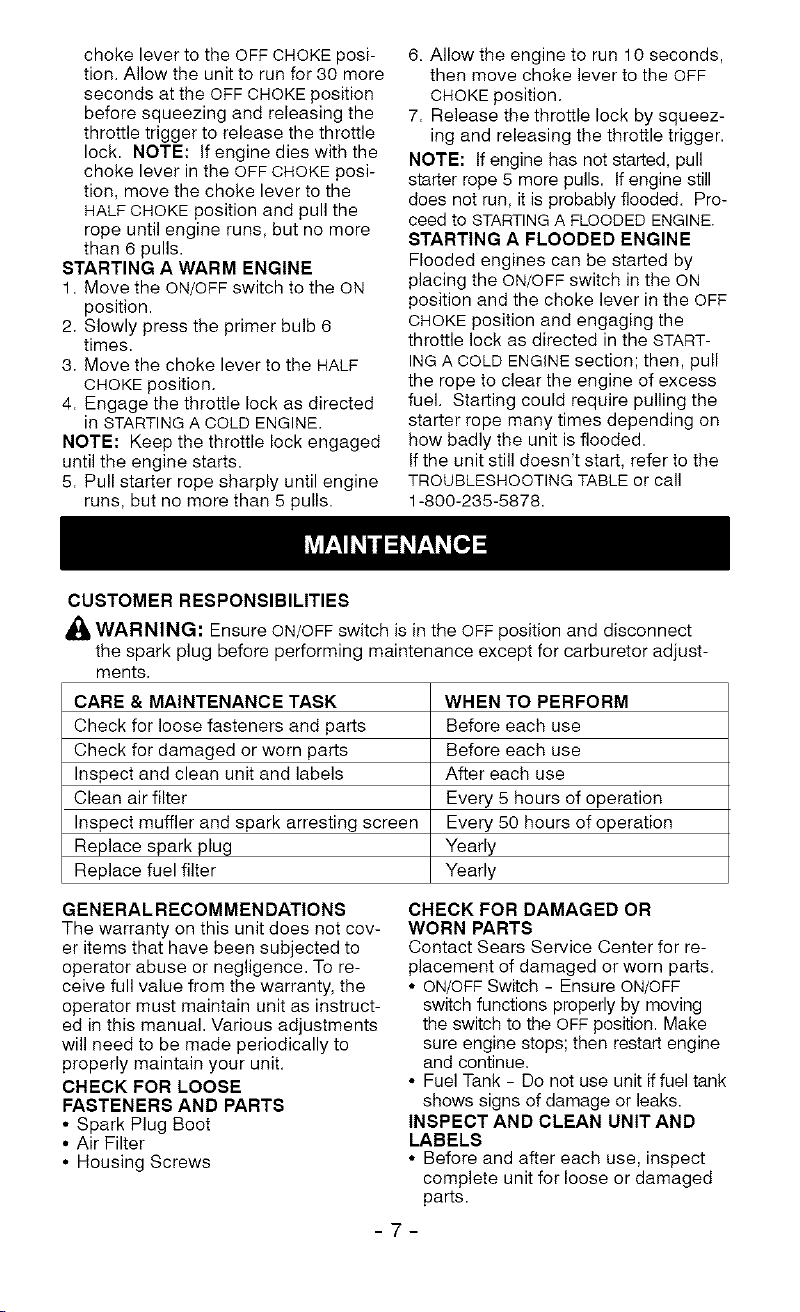

CUSTOMER RESPONSIBILITIES

_t WARNING: Ensure ON/OFF switch is in the OFF position and disconnect

the spark plug before performing maintenance except for carburetor adjust-

ments.

CARE & MAINTENANCE TASK WHEN TO PERFORM

Check for loose fasteners and parts Before each use

Check for damaged or worn parts Before each use

Inspect and clean unit and labels After each use

Clean air filter Every 5 hours of operation

Inspect muffler and spark arresting screen Every 50 hours of operation

Replace spark plug Yearly

Replace fuel filter Yearly

GENERAL RECOMMEN DATIONS

The warranty on this unit does not cov-

er items that have been subjected to

operator abuse or negligence. To re-

ceive full value from the warranty, the

operator must maintain unit as instruct-

ed in this manual. Various adjustments

will need to be made periodically to

properly maintain your unit.

CHECK FOR LOOSE

FASTENERS AND PARTS

• Spark Plug Boot

• Air Filter

• Housing Screws

CHECK FOR DAMAGED OR

WORN PARTS

Contact Sears Service Center for re-

placement of damaged or worn parts.

• ON/OFF Switch - Ensure ON/OFF

switch functions properly by moving

the switch to the OFF position. Make

sure engine stops; then restart engine

and continue.

• Fuel Tank - Do not use unit if fuel tank

shows signs of damage or leaks.

INSPECT AND CLEAN UNIT AND

LABELS

• Before and after each use, inspect

complete unit for loose or damaged

parts.

-7-

Loading ...

Loading ...

Loading ...