Loading ...

Loading ...

Loading ...

CUSTOMER RESPONS BmLITIES

t=l=l=l,l,i i

V-BELTS

Check V-belts for deterioration and wear after t00 hours of

operation and replace if necessary. The belts are not

adjustable. Replace belts if they begin to slip from wear.

TRANSAXLE COOLING

Keep transaxle free from build-up of dirt and chaff which

can restrict cooling.

ENGINE

LUBRnCATION

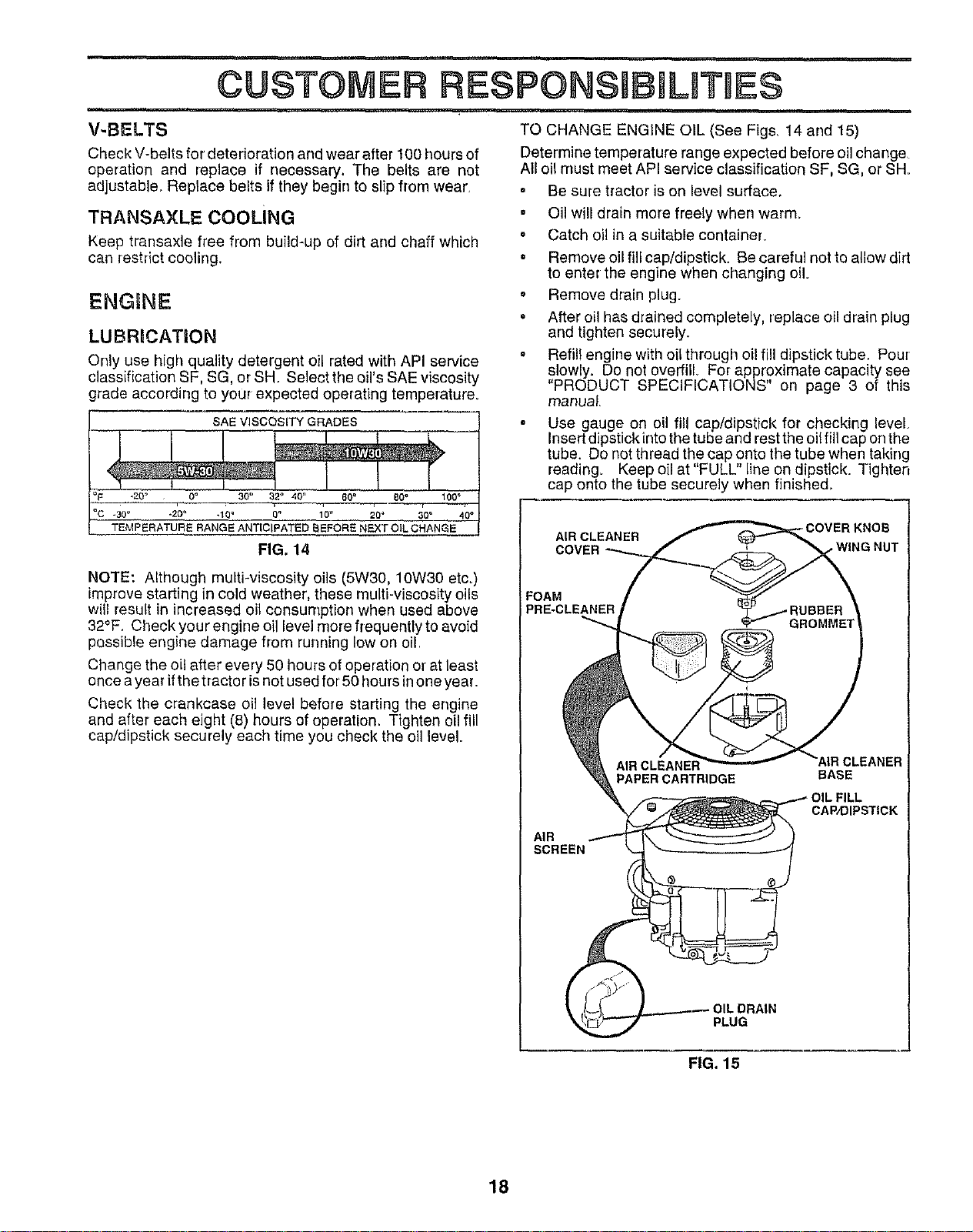

Only use high quality detergent oil rated with API service

classification SF, SG, or SH. Select the oil's SAE viscosity

grade according to your expected operating temperature.

SAE VISCQSITY GRADES

-20= 0_ 30"

.30 ° .20 _ ,1Q_ 0o 10_ 20_ 30 =

TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OiL CHANGE

FIG. 14

NOTE: Although multi-viscosity oils (5W30, 10W30 etco)

improve starting in cold weather', these multioviscosity oils

will result in increased oil consumption when used above

32°F. Check your engine oil level more frequently to avoid

possible engine damage from running low on oil

Change the oil after every 50 hours of operation or at least

once a year ifthe tractor isnot used for 50 hours inone year.

Check the crankcase oil level before starting the engine

and after each eight (8) hours of operation. Tighten oil fill

cap/dipstick securely each time you check the oil level.

TO CHANGE ENGINE OIL (See Figs. 14 and 15)

Determine temperature range expected before oil change_

All oil must meet API service classification SF, SG, or SH_

o Be sure tractor is on level surface.

= Oil will drain more freely when warm_

• Catch oil in a suitable container_

o Remove oil fill cap/dipstick. Be careful not to allow dirt

to enter the engine when changing oil.

o Remove drain plug.

° After oil has drained completely, replace oil drain plug

and tighten securely.

° Refill engine with oil through oi! fill dipstick tube. Pour

slowly. Do not overfill For approximate capacity see

"PRODUCT SPECIFICATIONS" on page 3 of this

manual,

Use gauge on oil fill cap/dipstick for checking level

Insert dipstick into the tube and rest the oil fill cap on the

tube, Do not thread the cap onto the tube when taking

r&_d';nng° t#e_PbOi,saetc_ULawl_e_in d_PeStick.Tighten

-.COVER KNOB

AIR CLEANER

COVER , WING NUT

FOAM

PRE-CLEANER

AIR

SCREEN

CAP/DIPSTICK

'RAIN

PLUG

FIG. 15

18

Loading ...

Loading ...

Loading ...