Loading ...

Loading ...

Loading ...

6

TABLE 1 - COOLING OIL - Dielectric

SUPPLIER GRADE

Shell Turbo oil 32

Texaco Rando HD32

Mobile D.T.E. Oil Light

G & G Oil Circulating 22

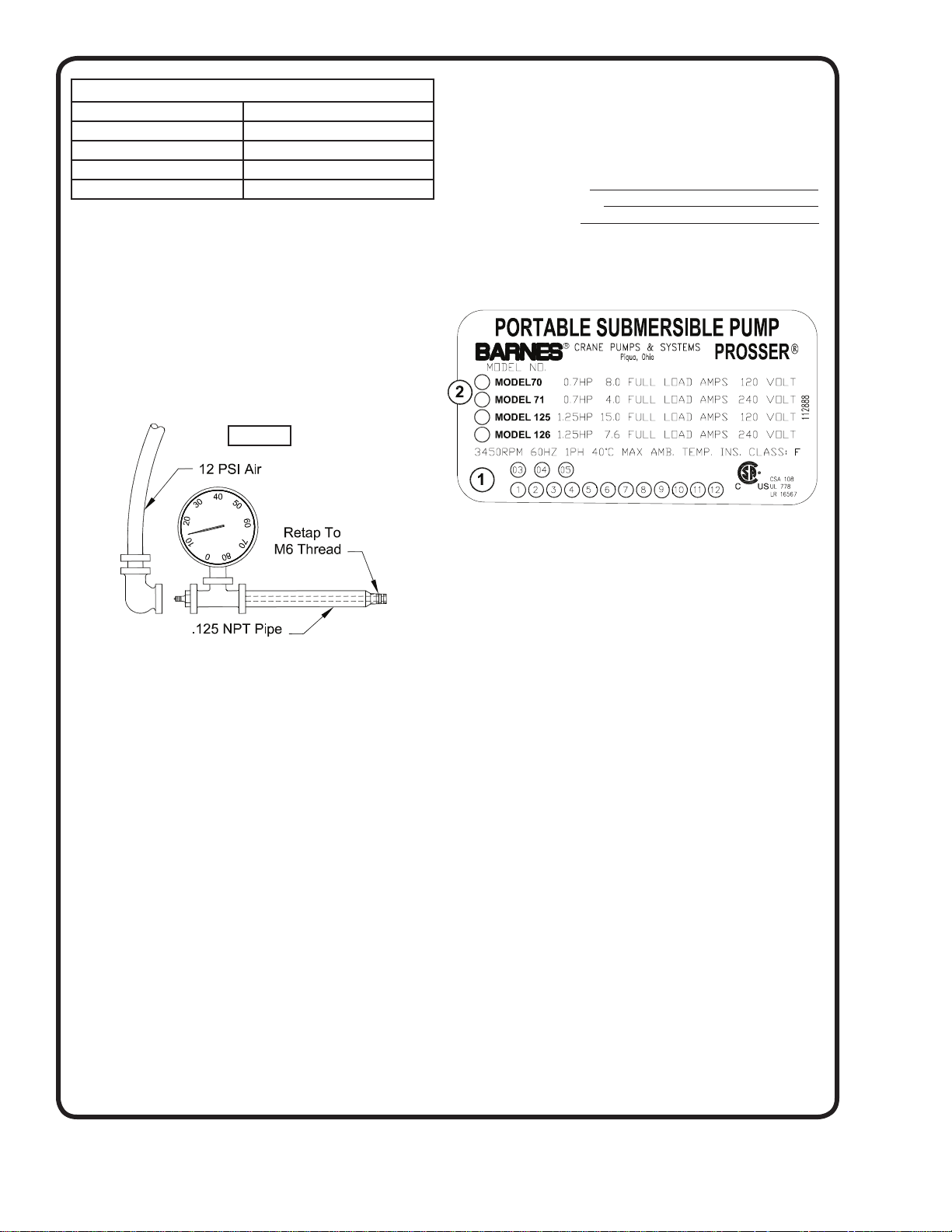

F-1.3) Seal Cavity Pressure Test:

Remove the socket head screw (9) and o-ring (8) from

the hole marked “OIL” and check for correct amount of

oil. Apply pipe sealant to pressure gauge assembly and

tighten into hole (See Figure 1). Pressure seal chamber

to 12 PSI and check for leaks. If after fi ve minutes,

the pressure is still holding constant, and no leaks are

observed, slowly bleed the pressure and remove the

gauge assembly. Replace socket head screw (9) with

o-ring (8) using a sealant. If the pressure does not hold,

then the leak must be located and repaired.

F-2) Impeller Replacement:

Please refer to instructions included with the Repair Parts

Kit.

F-3) Mechanical Seal Replacement:

Please refer to instructions included with the Repair Parts

Kit.

F-4) Power Supply Cord Replacement:

Please refer to instructions included with the Repair Parts

Kit.

F-5) Discharge Nozzle Replacement:

Please refer to instructions included with the Repair Parts

Kit.

F-6) Strainer Replacement:

Please refer to instructions included with the Repair Parts

Kit.

SECTION G - WARRANTY REPAIR AND

REPLACEMENT PARTS

G-1) Information Needed:

Always furnish the following information:

1. Pump Part Number

2. Pump Model Number

3. Pump Date Code

NOTE: Record your pump information here for future

reference.

G-2) Part Number:

The Part Number consists of a six (6) digit number, which

appears in the catalog and page 3 of this manual. This

number is used for ordering and obtaining information.

G-3) Model Number:

This designation consists of numbers and letters which

represents the horsepower, motor phase, voltage and

pump design.

G-4) Date Code:

The Date Code consists of two numbers that are punched

holes in the nameplate. This specifi es the month and year

indicating the date the unit was built.

Figure 1

Loading ...

Loading ...

Loading ...