Loading ...

Loading ...

Loading ...

<Failure example>

Ifthereisanobstacleintheairowpathorproperinstallation

space is not provided, the indoor unit will cause air volume

reduction and take in air blown out of the indoor unit,

thus resulting in performance degradation or turning the

thermostat OFF frequently.

CAUTION

• Install the indoor and outdoor units, power supply wiring,

remote controller wiring and transmission wiring at least

1 meter away from televisions or radios to prevent image

interference or noise.

(Depending on the radio waves, a distance of 1 meter may

notbesufcienttoeliminatethenoise.)

• Installtheindoorunitasfaraspossiblefromuorescent

lamps.

If a wireless remote controller kit is installed, the

transmission distance may be shorter in a room where

an electronic lighting type (inverter or rapid start type)

uorescentlampisinstalled.

(2) Use suspension bolts to install the unit.

Check whether or not the ceiling is strong enough to

support the weight of the unit. If there is a risk that the

ceiling is not strong enough, reinforce the ceiling before

installing the unit.

4. PREPARATION BEFORE INSTALLATION

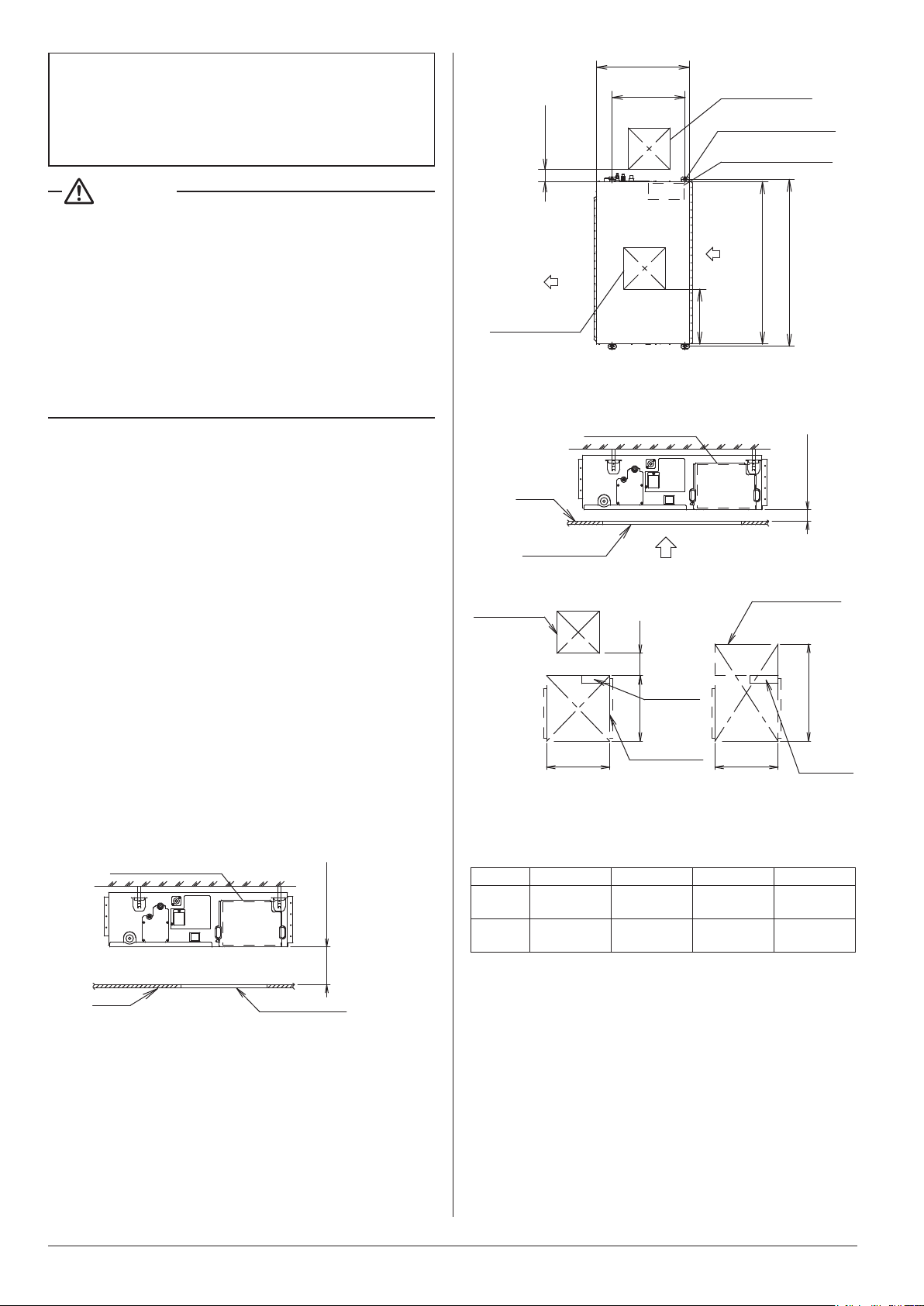

(1) Check the relation of location between the ceiling

opening and the indoor unit suspension bolts. (unit:

inch (mm))

• Provide one of the following service spaces for the

maintenance and inspection of the electrical wiring box

and drain pump or for other services.

1. Inspection ports 1 and 2 (17-11/16 inch (450mm) ×

17-11/16 inch (450mm)) (Fig. 3-2) and a minimum

space of 11-13/16 inch (300mm) at the bottom of the

product (Fig. 3-1).

2. Inspection port 1 (17-11/16 inch (450mm) ×

17-11/16 inch (450mm)) on the electrical wiring box

side and inspection port 2 on the bottom of the

product. (Fig. 4, arrow A-1)

3. Inspection port 3 on the bottom of the product and on

the bottom side of the electrical wiring box. (Fig. 4,

arrow A-2)

Electrical wiring box

11-13/16 (300)

or more

Ceiling

Inspection port

< In the case of (1)-1 >

unit: inch (mm)

Fig. 3-1

Electrical wiring box

31-1/2 (800)

7-7/8 (200)

or less

C

B

D

(Suspension bolt pitch)

Suspension bolt (× 4)

24-13/16

(630)

Air outlet

Bottom of

indoor unit

* Inspection port 2 is not required

if the bottom space under the product

is accessible for work.

Air inlet

(Suspension

bolt pitch)

Inspection port 1

(17-11/16 (450)×

17-11/16 (450))

Inspection port 2*

(17-11/16 (450)×

17-11/16 (450))

(For drain pan

removal and

component

replacement)

Fig. 3-2 unit: inch (mm)

Electrical wiring box

13/16 (20)

or more

Ceiling

Inspection port

A

Inspection port 1

(17-11/16 (450)×

17-11/16 (450))

Inspection

port 3

Electrical

wiring box

Electrical

wiring box

31-1/2

(800)

Arrow A-1 Arrow A-2

Inspection port 2

(Indoor unit size

+ 11-13/16 (300)

or more)

(Indoor unit

size or more)

7-7/8 (200)

or less

E=C+11-13/16 (300)

or more

C

< In the case of (1)-2, 3 >

31-1/2

(800)

Fig. 4 unit: inch (mm)

Table 1 unit: inch (mm)

B C D E

09/12

class

1-15/16 (50)

39-3/8

(1000)

40-7/8

(1038)

51-3/16

(1300)

15/18/24

class

(0)

27-9/16

(700)

29-1/16

(738)

39-3/8

(1000)

(2) Mount canvas ducts to the air outlet and inlet so that

the vibration of the indoor unit will not be transmitted

to the ducts or ceiling. Furthermore, attach sound

absorbing material (thermal insulation material) to

the duct inner walls and anti-vibration rubber to the

suspension bolts (refer to 8. DUCT WORK).

(3) The indoor unit is set to standard external static

pressure.

• If external static pressure is higher or lower than the

standard set value, the remote controller may be used

to make on-site setting change in the external static

pressure.

Refer to 10. FIELD SETTING.

5 English

Loading ...

Loading ...

Loading ...