Loading ...

Loading ...

Loading ...

12

BOTTLE, KEG & BACK BAR COOLERS, GLASS & PLATE CHILLERS

OPERATIONS MANUAL

KEG TAPPING INSTRUCTIONS

Because keg and tap types vary from brand to brand, contact

your beer distributor for specific keg tapping instructions.

INSTALLATION OF CO

2

CYLINDER AND REGULATOR

Pressurized CO

2

should be provided from outside the cabinet.

The supply hose can be routed through the access hole at the

back of the machine compartment and into the cabinet through

the knock-out plug located on the upper side wall (see Figure

9). The CO

2

dispensing gas must be reduced to 8-10 PSI by a

regulator (not supplied) and delivered to the manifold splitter

(on the left upper wall of cabinet) using the supplied hose and

clamps. Cut hose to length. The manifold splitter will separate

the gas into two or more lines to supply each keg tap. A check

valve on the manifold splitter prevents beer from backing up into

the supply hose and regulator.

IMPORTANT NOTE: Changing Kegs: defrosting of all keg

coolers is automatic, but since loading times vary, unplug

the cabinet and leave the doors open for at least 15 min-

utes during keg change, to keep ice from accumulating on

the evaporator coil. The temperature control (on the left

rear interior) is factory set to maintain keg temperatures

within 35°F to 40°F under normal conditions. It may take

several hours to cool a warm keg, so cold kegs should

be moved from chilled storage immediately into your

cabinet, to avoid warm or spoiled product. Before a new

barrel is tapped, purge CO

2

lines by quickly opening and

closing the outlet valve, allowing a surge of gas to travel

through the line and tap.

NOTE: Proper cleaning is extremely important for the beer

faucet, drain pan and any items coming in contact with food

or beverages, to prevent odors and tastes from bacteria. It is

normal for some sweating on or around each draft tower and

door opening, under conditions of high humidity.

Model

No. of

Doors

Net Capacity

(Cu. Ft.)

Barrel-Type

Keg Qty.

Straight-Wall

Keg Qty.

KC24

1 8 1 1

KC50

2 16 - 2

KC50S

2 13 - 2

KC59

2 22 2 3

KC59S

2 15 2 2

KC69

2 26 3 3

KC69S

2 18 3 3

KC79

3 28 4 4

KC79S

3 22 3 3

KC90

3 35 4 5

KC90S

3 25 4 4

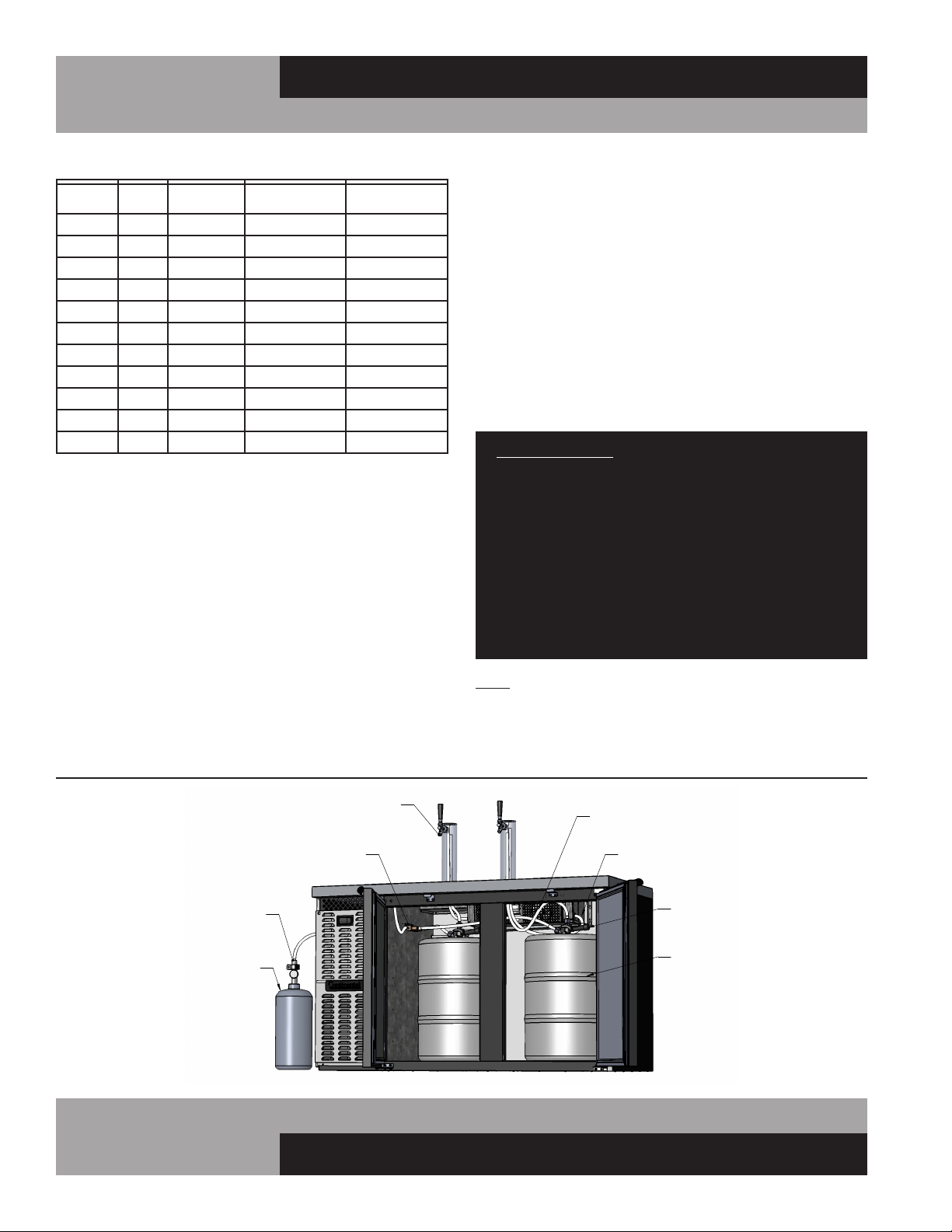

DIRECT DRAW DRAFT BEER SET-UP (Keg Coolers)

Your new unit will provide cold storage for barrel-type or

straight-side kegs (see Table above for capacities). To install

dispensing towers (see Figure 9), place a rubber washer over

tower mounting holes in the top of the cabinet and secure

tower(s) using fine thread machine screws supplied in cabinet

top (do not use wood screws supplied with tower). The hose

line from tower must go through hole in top and be attached to

the keg tap (supplied by others). Install the cold air tubes from

inside the cabinet by pushing each tube as far as it will go into

its closest tower hole. About 8” of tube will feed into the tower.

For your convenience, a cleanout drain hose is provided from

the behind the front grill with 3 ft. of hose for an external drain

connection to be made by installer. If a beer waste jar is to be

installed, the drain line (on the left front interior floor) can be cut.

Keg Cooler Capacities

w/COOLING HOSE

(BY OTHERS)

CO2 TANK

COLD AIR HOSE

REGULATOR

KEG TAP

C02 HOSES

(BY OTHERS)

DISPENSING TOWER

KEGS

(BY OTHERS)

(BY OTHERS)

(BY OTHERS)

MANIFOLD

SPLITTER

FIGURE 9:

Typical Keg Cooler Tap Set-Up

Loading ...

Loading ...

Loading ...