Loading ...

Loading ...

Loading ...

TYPICAL OPERATIONS (Continued)

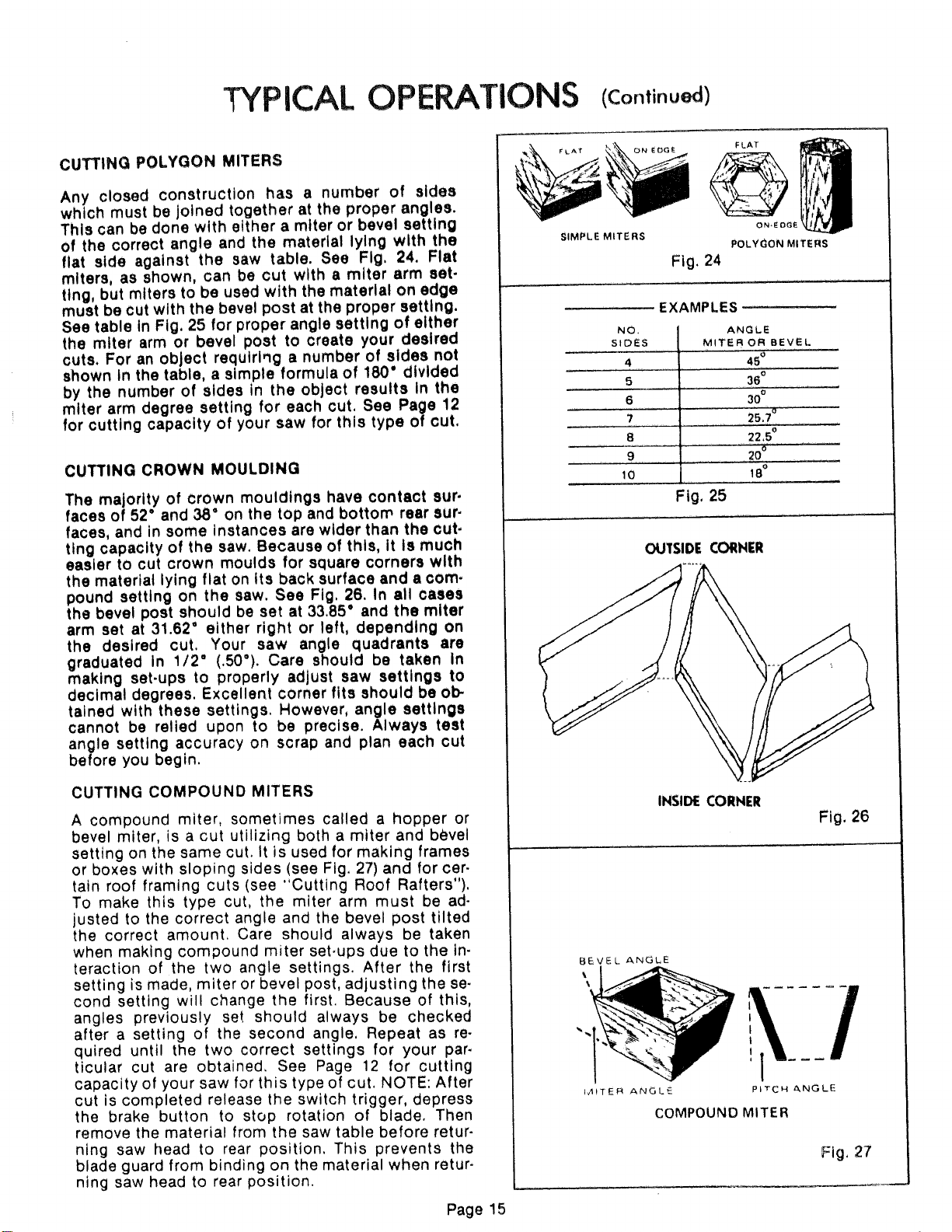

CUTTING POLYGON MITERS

Any closed construction has a number of sides

which must be joined together at the proper angles.

This can be done with either a miter or bevel setting

of the correct angle and the material lying with the

flat side against the saw table. See Fig, 24. Fiat

miters, as shown, can be cut with a miter arm set-

tlng, but miters to be used with the material on edge

must be cut with the bevel post at the proper setting.

See table In Fig, 25 for proper angle setting of either

the miter arm or bevel post to create your desired

cuts. For an object requtrl,lg a number of sides not

shown In the table, a simple formula of 180' dtvlded

by the number of sides in the object results In the

miter arm degree setting for each cut. See Page 12

for cutting capacity of your saw for this type of cut.

CUTTING CROWN MOULDING

The majority of crown mouldings have contact sur.

faces of 52" and 38 ° on the top and bottom rear cur.

faces, and in some instances are wider than the cut.

ttng capacity of the saw. Because of this, it ts much

easier to cut crown moulds for square corners with

the material lying flat on its back surface and a com.

pound setting on the saw. See Fig, 26. in all cases

the bevel post should be set at 33.85' and the miter

arm set at 31.62' either right or left, depending on

the desired cut. Your saw angle quadrants are

graduated In 1/2 ° (.50°). Care should be taken In

making set-ups to properly adjust saw settings to

decimal degrees. Excellent corner fits should be ob-

tained with these settings, However, angle settings

cannot be relied upon to be precise. Always test

angle setting accuracy on scrap and plan each cut

before you begin.

CUTTING COMPOUND MITERS

A compound miter, sometimes called a hopper or

bevel miter, is a cut utilizing both a miter and bevel

setting on the same cut. It is used for making frames

or boxes with sloping sides (see Fig. 27) and for cer-

tain roof framing cuts (see "Cutting Roof Rafters").

To make this type cut, the miter arm must be ad-

justed to the correct angle and the bevel post tilted

the correct amount, Care should always be taken

when making compound miter set,ups due to the in-

teraction of the two angle settings. After the first

setting is made, miter or bevel post, adjusting the se-

cond setting will change the first. Because of this,

angles previously set should always be checked

after a setting of the second angle, Repeat as re-

quired until the two correct settings for your par-

ticular cut are obtained, See Page 12 for cutting

capacity of your saw for this type of cut. NOTE: After

cut is completed release the switch trigger, depress

the brake button to stop rotation of blade, Then

remove the material from the saw table before retur-

ning saw head to rear position, This prevents ttle

blade guard from binding on the material when retur-

ning saw head to rear position.

Page 15

FLAT

ON_EOG_

POLYGON MITERS

Fig. 24

EXAMPLES

NO,

SIDES

4

5

6

?

8

9

10

ANGLE

MITER OR BEVEL

45°

36°

30°

22,5°

20°

18°

Fig, 25

OUTSIDE CORNER

INSIDE CORNER

Fig. 26

i_.l_T E R ANGL_

PITCH ,_,NG LE

COMPOUND MITER

Fig, 27

Loading ...

Loading ...

Loading ...