Loading ...

Loading ...

Loading ...

ADJUSTING TILT GAGE -- Using

an accurate square, set saw blade at

right angles to table top. Then adjust

the pointer on the tilt gage (D, fig. 2)

to *'0".

ADJUSTING MITER GAGE SCALE

Using an accfirate square, block the

miter gage at the square position. Make

a trial cut on a fairly wide board, then

check this cut with the square. If cut

is accurate, set the pointer on the miter

gage scale (K, fig. 2) to "90". _

ADJUSTING FENCE INDICATORS

_Adjust right-hand fence indlcatoI

(part 135, fig. 4) by positioning fence

T

/

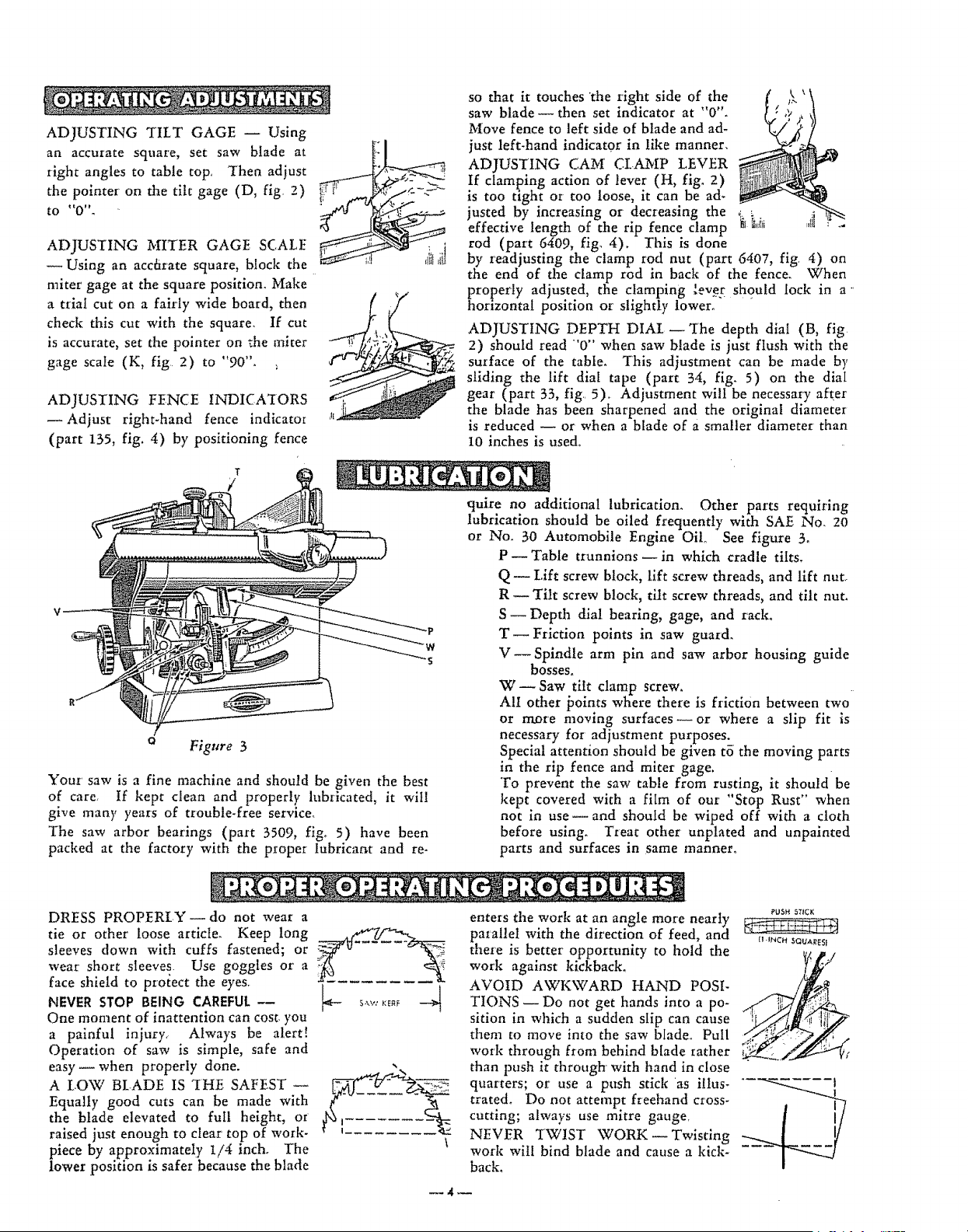

o Figure 3

Your' saw is a fine machine and should be given the best

of care. tf kept clean and properly lubricated, it will

give many years of trouble-free service°

The saw arbor bearings (part 3509, fig° 5) have been

packed at the factory with the proper lubricant and re-

so that it touches 'the right side of the

saw blade--then set indicator at "0".

Move fence to left side of blade and ad-

just left-hand indicator in like manner.

ADJUSTING CAM CLAMP LEVER

If clamping action of lever (H, fig° 2)

is too tight or too loose, it can be ad.

justed by increasing or decreasing the ,_.L

effective length of the rip fence clamp _t_iii ,,Iii _ ..

rod (part 6409, fig. 4). This is done

by readjusting the clamp rod nut (part 6407, fig. 4) on

the end of the clamp rod in back of the fence. When

properly adjusted, the clamping **ever should lock in a"

horizontal position or slightly lower[ "_ "

ADJUSTING DEPTH DIAI. _ _[he depth dial (B, fig

2) should read "0" when saw blade is just flush with the

surface of the table. This adjustment can be made by

sliding the lift dial tape (part 34, fig. 5) on the dial

gear (part 33, fig.. 5). Adjustment will be necessary after

the blade has been sharpened and the original diameter

is reduced -- or when a blade of a smaller diameter than

10 inches is used°

quire no additional lubrication_ Other parts requiring

lubrication should be oiled frequently with SAE No. 20

or No_ 30 Automobile Engine Oilo See figure 3.

P_Table trunnions _in which cradle tilts.

Q _ Lift screw block, lift screw threads, and lift nut_

R _ Tilt screw block, tilt screw threads, and tilt nut.

S _ Depth dial bearing, gage, and rack°

T _ Friction points in saw guard.

V _ Spindle arm pin and saw arbor housing guide

bosses.

W _ Saw titt clamp screw.

A!l other _oints where there is friction between two

or more moving surfaces _ or where a slip fit is

necessary for adjustment purposes.

Special attention should be given t6 the moving parts

in the rip fence and miter' gage.

To prevent the saw table from rusting, it should be

kept covered with a film of our "Stop Rust" when

not in use_ and should be wiped off with a cloth

before using. Treat other unplated and unpainted

parts and surfaces in same manner.

DRESS PROPERLY _ do not wear a

tie or other loose article. Keep long

sleeves down with cuffs fastened; or

wear short sleeves Use goggles or a

face shield to protect the eyes.

NEVER STOP BEING CAREFUL

One moment of inattention can cost, you

a painful injury, Always be alert!

Operation of saw is simple, safe and

easy _ when properly done.

A LOW BLADE IS THE SAFEST

Equally good cuts can be made with

the blade elevated to full height, or

raised just enough to clear top of work-

piece by approximately I/4 inch, The

lower position is safer because the blade

\

enters the work at an angle more nearly

parallel with the direction of feed, and

there is better opportunity to hold the

work against kickback.

AVOID AWKWARD HAND POSI-

TIONS _ Do not get hands into a po-

sition in which a sudden slip can cause

them to move into the saw blade.. Pull

work through from behind blade rather

than push it through with hand in close

quarters; or use a push stick as illus-

tratedo Do not attempt freehand cross-

cutting; always use mitre gauge_

NEVER TWIST _¢/ORK_Twisting

work will bind blade and cause a ldck-

back,

_USH 5i'lCl(

()-INCH SQUA_'[51

Loading ...

Loading ...

Loading ...