Loading ...

Loading ...

Loading ...

14

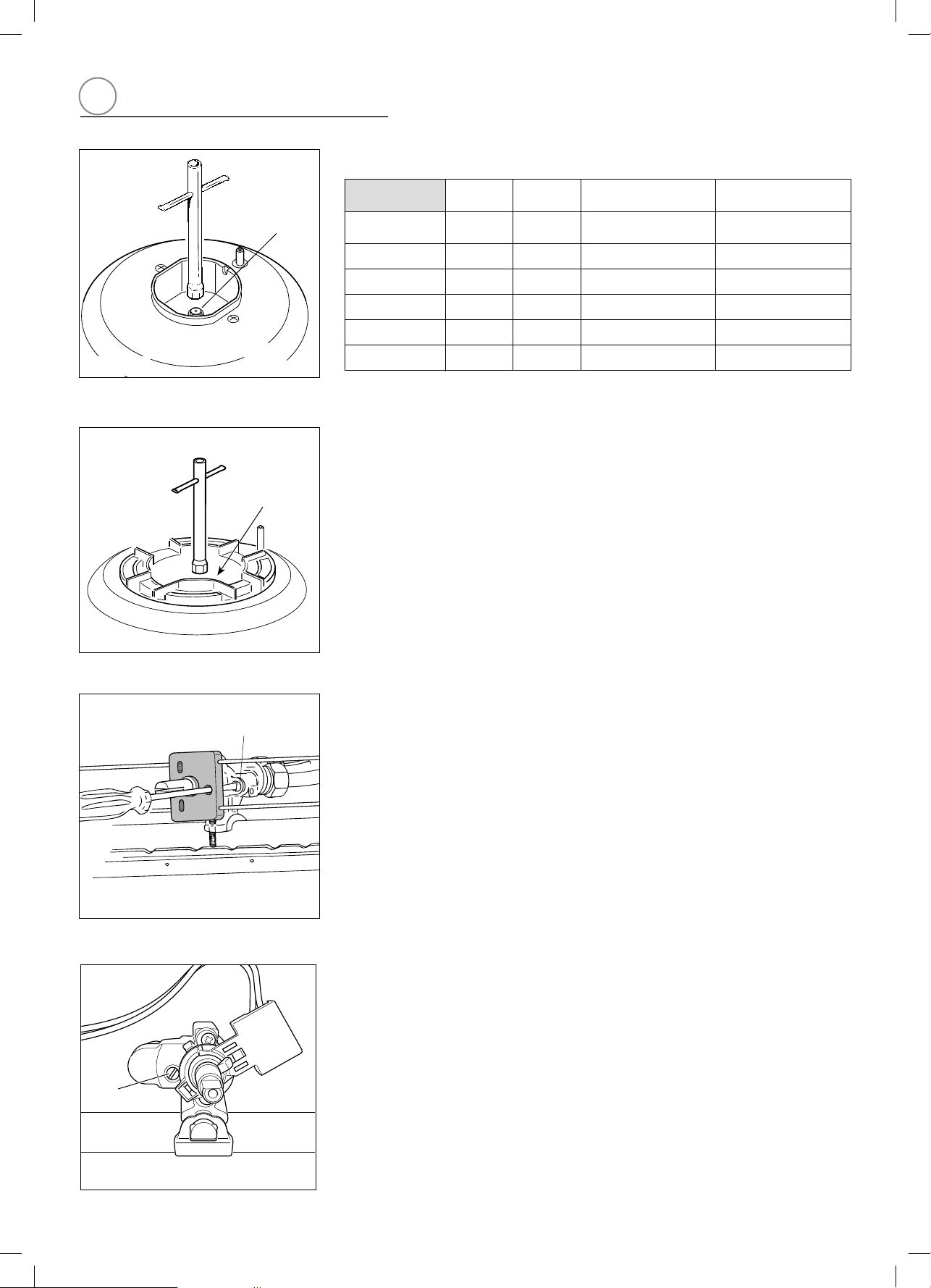

SETTING THE BURNER MINIMUM (Valves may vary)

When switching from one type of gas to another, the minimum flow rate must also be

correct: the flame should not go out even when passing suddenly from maximum to

minimum flame.

To regulate the flame follow the instructions below:

–

Light

the burner

–

Set

the gas valve to

LO position

–

Remove

the knob

– With a thin screwdriver, turn the regulation screw (Figs. 2.9a and 2.9b) until

adjustment

is correct. On some valves, you need to pass by the hole of the

micr

oswitch (Fig. 2.9a) to turn the regulation screw.

For LP/PROPANE gas, tighten the regulation screws completely.

Oven burner

13000 1500 109 180

Broil burner

8500 - 88 146

OPERATIONS TO BE PERFORMED WHEN SUBSTITUTING

THE INJECTORS

✓ Remove the gratings, the burner covers and the knobs;

✓ Using a wrench substitute the nozzle injectors “J” (figs. 2.7 - 2.8) with those most

suitable for the kind of gas for which it is to be used.

The burner are conceived in such a way so as not to require the regulation of the

primary air.

INJECTORS TABLE

NOMINAL

POWER

REDUCED

POWER

LP/PROPANE

11” W.C.P.

NATURAL GAS

4” W.C.P.

BURNERS

BTU/hr BTU/hr

Ø injector

[1/100 mm]

Ø injector

[1/100 mm]

Auxiliary (AUX)

3500 1000 55 90

Semirapid (SR)

6000 1500 72 118

Triple ring (TC)

12000 5000 102 170

Fig. 2.7

J

Fig. 2.8

J

2

Fig. 2.9a

Regulation screw

regulation screw

Regulation

screw

G

H

OR

Fig. 2.9b

Loading ...

Loading ...

Loading ...