Loading ...

Loading ...

Loading ...

MAINTENANCE / HELPFUL HINTS

B. Wet outer edge of "O" Ring with detergent solution.

C. With finger pressure press seat firmly and squarely

into cavity. See Figure 9A. Polished face of seat faces

inside of pump. If seat vdll not locate properly, place

cardboard washer over polished face and use piece of

3/4" standard pipe for pressing purposes. See Figure

9B.

Figure 9A Figure 9B

483 0194

D. Dispose of cardboard washer and clean surface of

seat.

E. Clean motor shaft.

F. Reassemble back half of pump to motor.

G. Apply detergent solution to inside diameter of rotat-

ing seal member.

H. Sfide rotating member on shaft until rubber drive ring

hits shaft shoulder. NOTICE: BE SURE you do not chip

or scratch seal face on shaft shoulder or seal v_Rl leak!

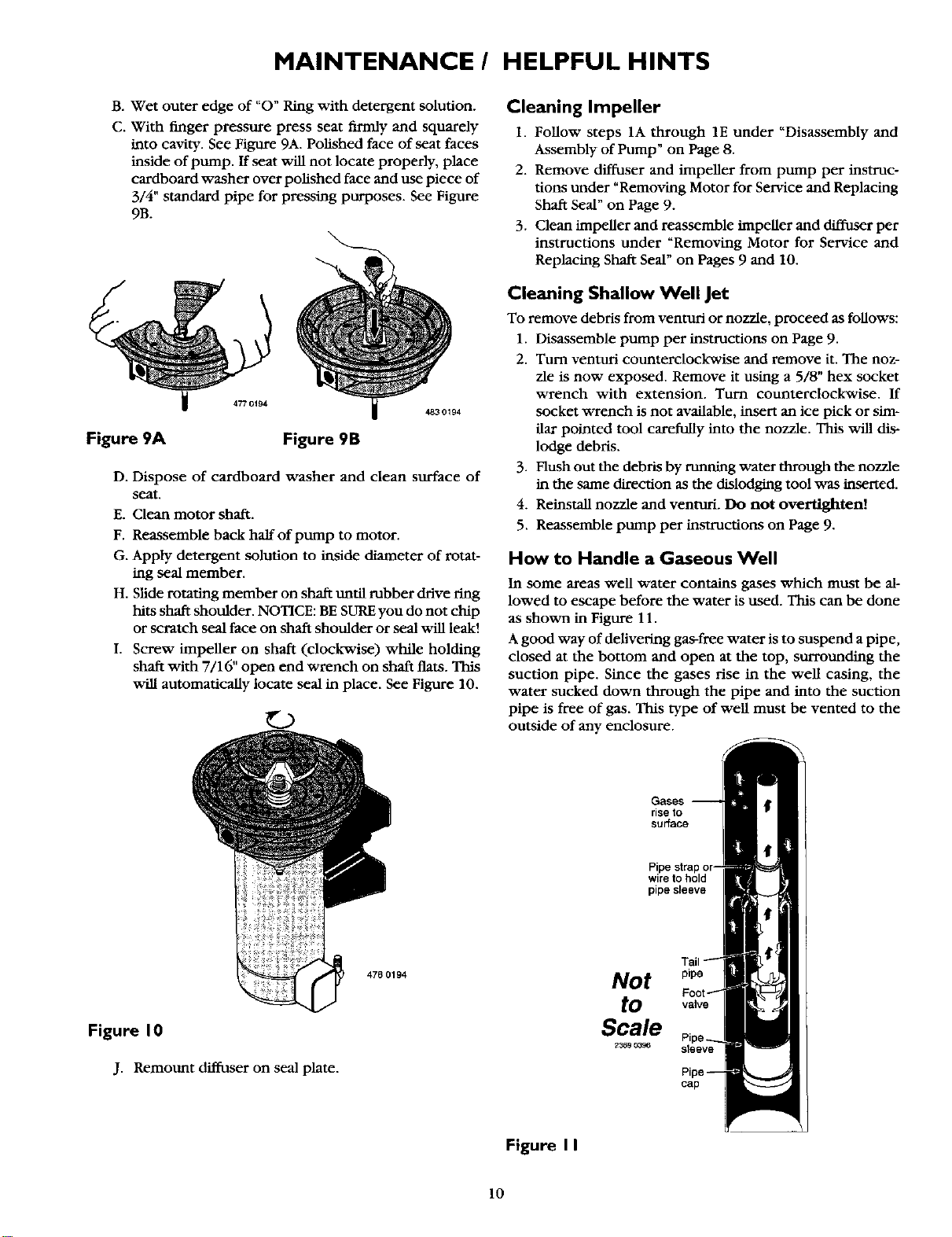

I. Screw impeller on shaft (clockwise) while holding

shaft with 7/16" open end wrench on shaft flats. This

will automatically locate seal in place. See Figure 10.

Cleaning Impeller

I. Follow steps 1A through 1E under "Disassembly and

Assembly of Pump" on Page 8.

2. Remove diffuser and impeller from pump per instruc-

tions under "Removing Motor for Service and Replacing

Shaft Seal" on Page 9.

3. Clean impeller and reassemble impeller and diffuser per

instructions under "Removing Motor for Service and

Replacing Shaft Seal" on Pages 9 and 10.

Cleaning Shallow Well Jet

To remove debris from venturi or nozzle, proceed as follows:

1. Disassemble pump per instructions on Page 9.

2. Turn venturi counterclockwise and remove it. The noz-

zle is now exposed. Remove it using a 5/8" hex socket

wrench with extension. Turn counterclockwise. If

socket wrench is not available, insert an ice pick or sim-

ilar pointed tool carefully into the nozzle. This will dis-

lodge debris.

3. Flush out the debris by running water through the nozzle

in the same direction as the dislodging tool was inserted.

4. Reinstall nozzle and venturi. Do not overtighten!

5. Reassemble pump per instructions on Page 9.

How to Handle a Gaseous Well

In some areas well water contains gases which must be al-

lowed to escape before the water is used. This can be done

as shown in Figure 11.

A good way of delivering gas-free water is to suspend a pipe,

closed at the bottom and open at the top, surrounding the

suction pipe. Since the gases rise in the well casing, the

water sucked down through the pipe and into the suction

pipe is free of gas. This type of well must be vented to the

outside of any enclosure.

_ase$

riseto

surface

wiretohold

pipe sleeve

Figure I0

J. Remount diffuser on seal plate.

478 0194

Not pip°

to valve

Scale

2369 _396 sleeve

cap

Figure I I

10

Loading ...

Loading ...

Loading ...