Loading ...

Loading ...

Loading ...

14

Bearings - Disassemble motor as per section F-3.1.

Remove snap ring (6) with snap ring pliers and pull motor

(1) and lower bearing (4) straight off of seal plate (2).

Inspect all parts for signs of wear and replace as needed.

CAUTION! Handle seal parts with extreme care.

do not scratch or mar lapped surfaces.

F-3.2) Replacing Bearing:

When replacing bearing, be careful to not damage the

rotor or shaft threads. Press the old bearing off the

shaft with an arbor press or gear puller. Clean the shaft

thoroughly. Apply adhesive compound to shaft and press

new bearing on, pushing only on the inner race, until it

seats against shoulder of shaft (see fi g.12).

IMPORTANT! - All parts must be clean before

reassembly.

F-3.3) Reassembly:

Make sure shaft seal (3) is clean and in proper position as

per section F-4.2 before reassembling rotor and bearing.

Slide lower bearing and rotor shaft squarely into the seal

plate (2) until bearing seats on the bottom. Insert snap

ring (6) into seal plate with fl at edge against outer race of

bearing. Place motor stator squarely onto seal plate (2)

and tighten motor screws. Install o-ring (13) onto seal plate

(2).

On BP & SE Series, slip motor wires through opening in

motor housing (14) see Figure 5. Connect motor wires to

cord set as per Figure 7. Place friction ring (9b) and gland

nut (9a) into motor housing (14) and tighten gland nut to

17.5 ft. lbs. On “AU” series pumps slip fl oat wires through

opening in motor housing (14) and connect to fl oat cable

(29) see Figure 8. Place friction ring (29b) and gland nut

(29a) into motor housing (14) and tighten gland nut to 17.5

ft. lbs.

Place motor housing (14) squarely onto seal plate (2).

Tighten socket head screws (15) into motor housing. Refi ll

with cooling oil as per paragraph F-1.3.

On BP-HT & SE-HT Series, slide the gland nut, friction

rings and grommet onto cord set (see Figure 6) and slip

cord through motor housing (14). Connect motor wires

per Figure 9. Place motor housing (14) squarely onto

seal plate while pulling excess cord through hole. Tighten

socket head screws (15) into motor housing. Slide the

friction rings (9b), grommet (9c) and gland nut (9a) into

motor housing and tighten gland nut to 17.5 ft. lbs. Refi ll

with cooling oil as per paragraph F-1.3. On “HTAU” series

pumps slide the gland nut, friction rings and grommet onto

cord set (see Figure 6) and slip cord (29) through motor

housing (14). Connect wires per Figure 10.

F-4) Shaft Seal Service

F-4.1) Dissassembly and Inspection:

Disassemble pump motor as per section F-3.1. Inspect

seal for signs of wear such as uneven wear pattern on

the stationary member or chips and scratches on either

sealing face. Do not interchange seal components.

Replace entire seal if damage occurs.

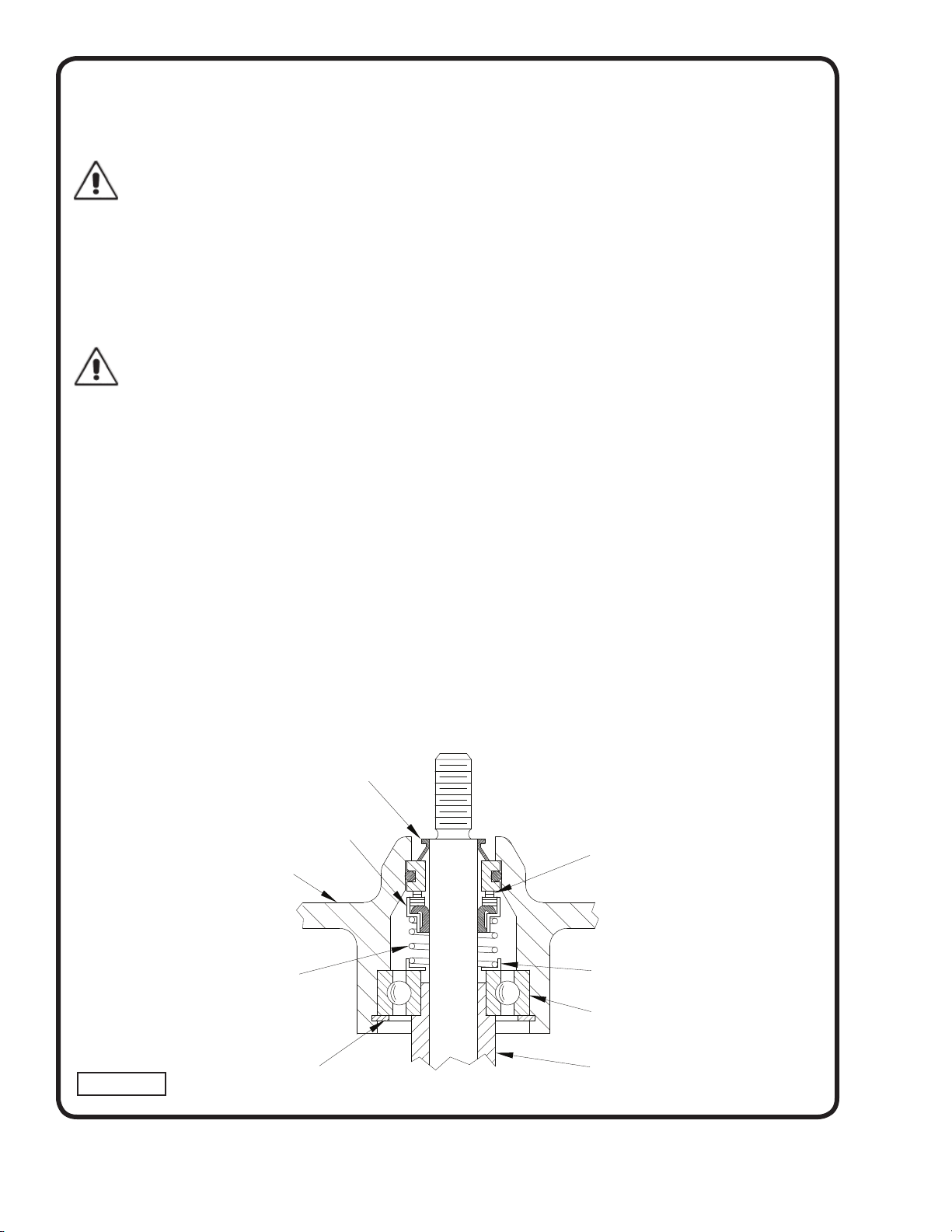

F-4.2) Replacing Shaft Seal (refer to fi g. 11, 12 & 13):

When replacing the shaft seal (3), remove used rotating

member (3c), spring (3b), and spring retainer (3a) from

motor shaft. Press used stationary member (3d) from the

seal plate (2). At reassembly, clean seal cavity thoroughly

and apply a light coat of oil. Lightly oil the rubber ring (DO

NOT use grease) and press the stationary member fi rmly

into the seal plate using a seal pusher (See Parts List-

Seal Tool Kit), nothing but pusher to come in contact with

seal face (see Fig. 11). Insert so that the fi nished surface

is up and the grooved surface is against the seal plate.

Make sure the stationary member is in straight and that the

rubber ring is not out of it’s groove.

Exclusion Seal

Bearing (4)

Seal Plate

Spring (3b)

Retaining Ring (6)

Stationary (3d)

Polished Mating Surface

Rotating Member (3c)

Sleeve (27)

MOTOR END

(Inboard End)

PUMP END

(Outboard End)

FIGURE 12

Retaining Ring (3a)

Loading ...

Loading ...

Loading ...