Loading ...

Loading ...

Loading ...

APPLICATIONS

You may use this tool for the purposes listed below:

• Straight line cutting operations such as cross cutting,

ripping, mitering, beveling, and compound cutting

• Dado or molding cuts with optional accessories

II Cabinet making and woodworking

NOTE=This table saw is designed to cut wood and wood

composition products only.

BASIC OPERATION OF THE TABLE SAW

The 3-prong plug must be plugged into a matching outlet

that is properly installed and groundedaccording to all

local codes and ordinances, Improper connection of the

equipmentcan result in electric shock. Do not modify

the plug if it will not fit the outlet. Have the correct outlet

installed by a qualified electrician. Refer to the Electrical

section inthis manual.

CAUSES OF KICKBACK

Kickback can occur when the blade stalls or binds, kick-

ing the workpiece back toward you with great force and

speed. Ifyour hands are near the saw blade, they may

be jerked loose from the workplace and may contact the

blade. Kiokback can cause serious injury. Use precautions

to avoid the risks.

Kickback can be caused by any action that pinches the

blade in the wood such as;

• Making a cut with incorrect blade depth

• SaWinginto knots or nails inthe workplace

• Twistingthe wood while making a cut

• Failing to support work

• Forcing a cut

• Cutting warped orwet lumber

• Using the wrong blade for the type of cut

• Not following correct operating procedures

• Misusing the saw

• Failing to use the anti-kickback pawls

• Cutting wlth a dull, gummed-up, or improperly set

blade

AVOIDING KICKBACK

• Always use the correct blade depth setting.The top of

the blade teeth should clear the workpiece by 1/8 in. to

1/4 in.

• Inspect the work for knots or nails before beginning a

cut. Knock out any loose knots with a hammer. Never

saw into a loose knot or nail.

• Always use the rip fence when rip cutting and the miter

gauge when cross cutting. This helps prevent twisting

the wood in the cut.

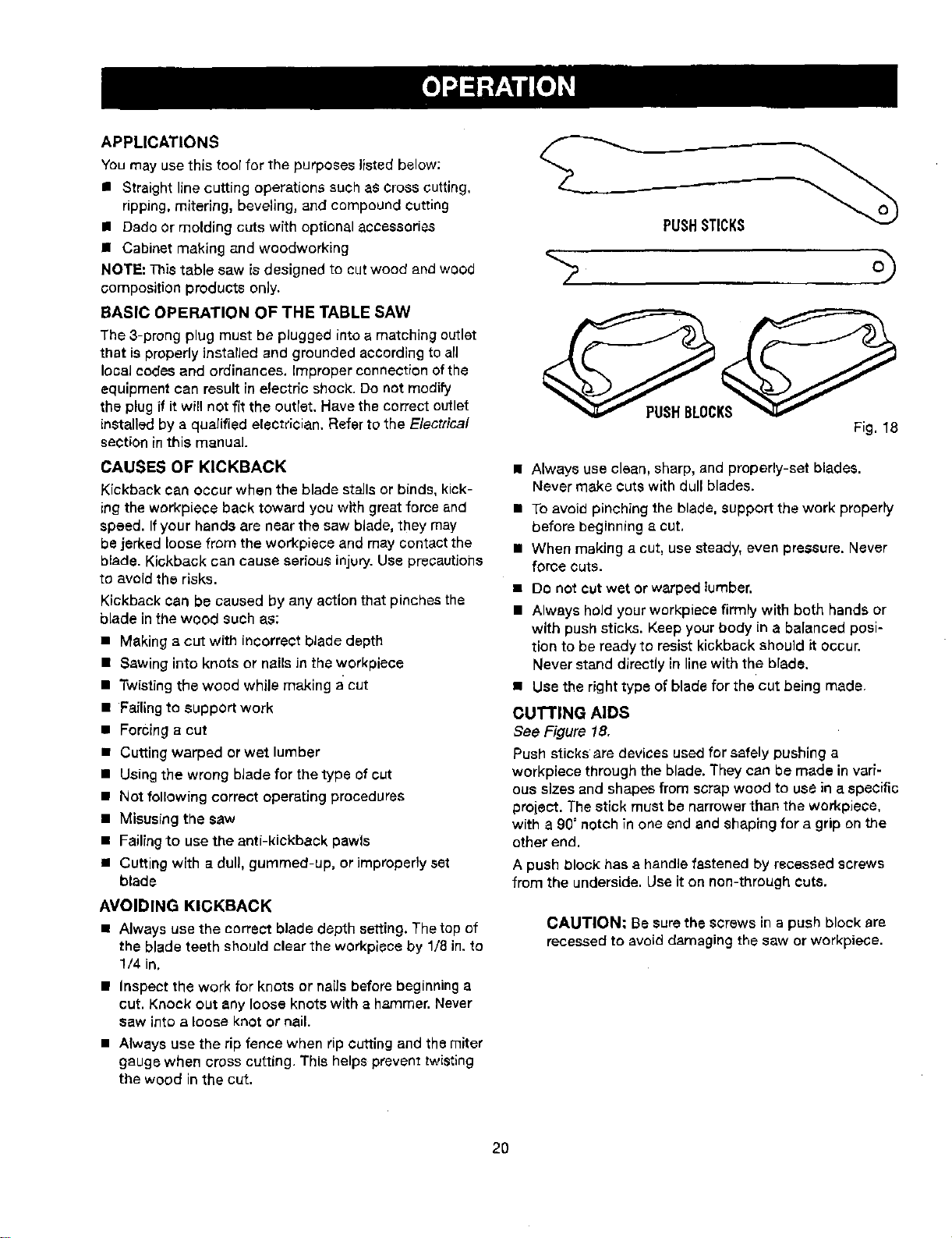

PUSHSTICKS

PUSHBLOCKS

Fig. 18

• Always use clean, sharp, and properly-set blades.

Never make cuts with dull blades.

• To avoid pinching the blade, support the work properly

before beginning a cut.

• When making a cut, use steady, even pressure. Never

force cuts.

• DOnot cut wet orwarped lumber.

• Always hold your werkpieee firmly with both hands or

with push st[cks. Keep your body [na balanced posi-

tion to be ready to resist kickback should it occur.

Never stand directly in line with the blade,

• Use the right type ofblade for the cut being made,

CUTI"ING AIDS

See Figure 18,

Push sticks •are devices used for safely pushing a

workplace through the blade. They can be made in vari-

ous sizesand shapes from scrap wood to use in a specific

project. The stick must be narrower than the workpiece,

with a 90°notch in one end and shapingfor a grip on the

other end.

A push block has a handle fastened by recessed screws

from the underside. Use it on non-through cuts.

CAUTION; Be surethe screws in a push block are

recessed to avoid damaging the saw or workplace.

20

Loading ...

Loading ...

Loading ...