Loading ...

Loading ...

Loading ...

ADJUSTMENTS TO COMPENSATE FOR WEAR

Even though the finest materials and precision workman-

ship have been used to minimize wear, after long use it

is reasonable to expect some wear. Adjustments have been

built into the Craftsman saw to reduce or eliminate this wear.

REMOVING RADIAL ARM SIDE PLAY

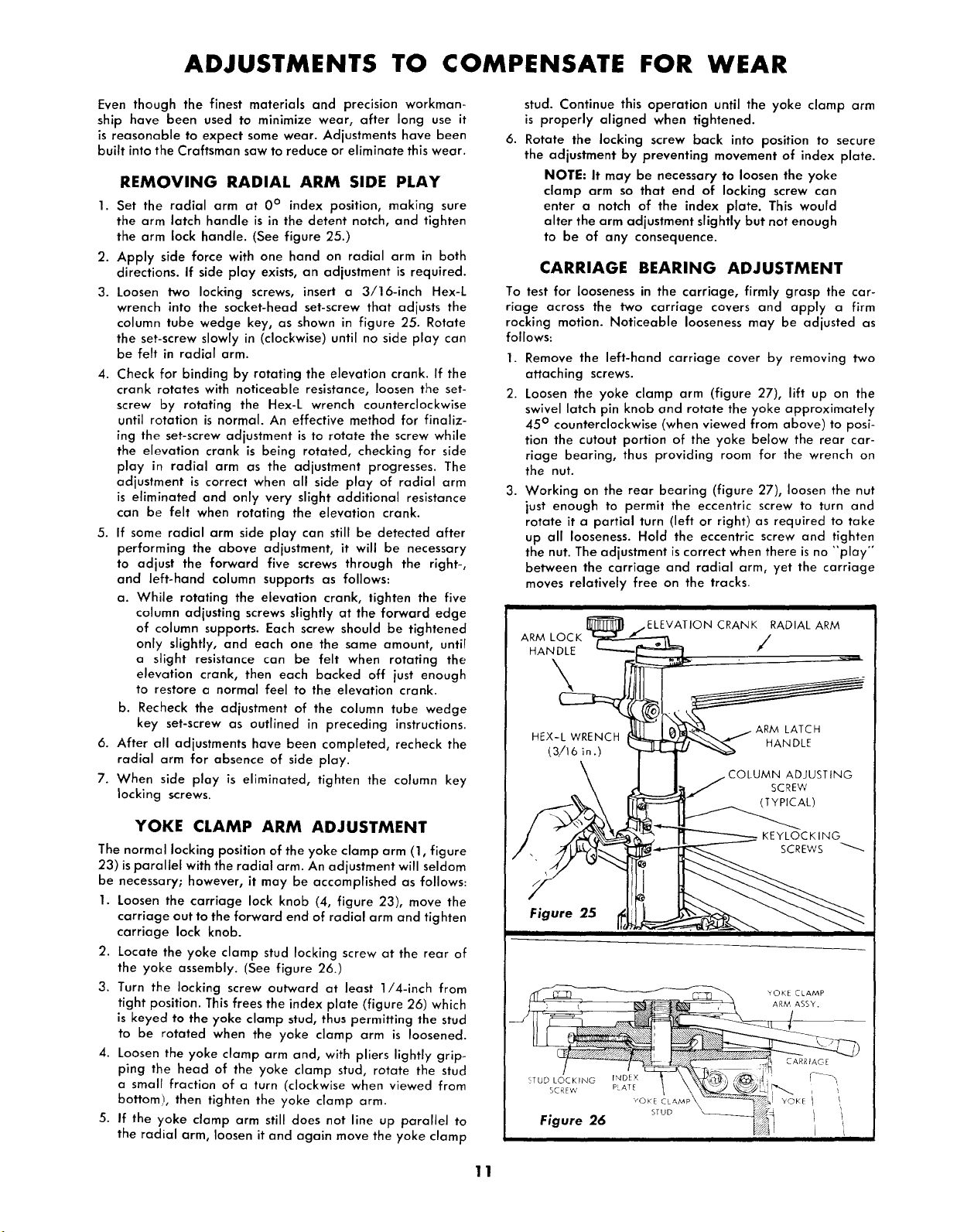

1. Set the radial arm at 0° index position, making sure

the arm latch handle is in the detent notch, and tighten

the arm lock handle. (See figure 25.)

2. Apply side force with one hand on radial arm in both

directions. If side play exists, an adjustment is required.

3. Loosen two locking screws, insert a 3/16-inch Hex-L

wrench into the socket-head set-screw that adjusts the

column tube wedge key, as shown in figure 25. Rotate

the set-screw slowly in (clockwise) until no side play can

be felt in radial arm.

4. Check for binding by rotating the elevation crank. If the

crank rotates with noticeable resistance, loosen the set-

screw by rotating the Hex-L wrench counterclockwise

until rotation is normal. An effective method for finaliz-

ing the set-screw adjustment is to rotate the screw while

the elevation crank is being rotated, checking for side

play in radial arm as the adjustment progresses. The

adjustment is correct when all side play of radial arm

is eliminated and only very slight additional resistance

can be felt when rotating the elevation crank.

5. If some radial arm side play can still be detected after

performing the above adjustment, it will be necessary

to adjust the forward five screws through the right-,

and left-hand column supports as follows:

a. While rotating the elevation crank, tighten the five

column adjusting screws slightly at the forward edge

of column supports. Each screw should be tightened

only slightly, and each one the same amount, until

a slight resistance can be felt when rotating the

elevation crank, then each backed off just enough

to restore a normal feel to the elevation crank.

b. Recheck the adjustment of the column tube wedge

key set-screw as outlined in preceding instructions.

6. After all adjustments have been completed, recheck the

radial arm for absence of side play.

7. When side play is eliminated, tighten the column key

locking screws.

YOKE CLAMP ARM ADJUSTMENT

The normal locking position of the yoke clamp arm (1, figure

23) is parallel with the radial arm. An adjustment will seldom

be necessary; however, it may be accomplished as follows:

1. Loosen the carriage lock knob (4, figure 23), move the

carriage out to the forward end of radial arm and tighten

carriage lock knob.

2. Locate the yoke clamp stud locking screw at the rear of

the yoke assembly. (See figure 26.)

3. Turn the locking screw outward at least 1/4-inch from

tight position. This frees the index plate (figure 26/which

is keyed to the yoke clamp stud, thus permitting the stud

to be rotated when the yoke clamp arm is loosened.

4. Loosen the yoke clamp arm and, with pliers lightly grip-

ping the head of the yoke clamp stud, rotate the stud

a small fraction of a turn (clockwise when viewed from

bottom!, then tighten the yoke clamp arm.

5. If the yoke clamp arm still does not line up parallel to

the radial arm, loosen it and again move the yoke clamp

stud. Continue this operation until the yoke clamp arm

is properly aligned when tightened.

6. Rotate the lacking screw back into position to secure

the adjustment by preventing movement of index plate.

NOTE: It may be necessary to loosen the yoke

clamp arm so that end of locking screw can

enter a notch of the index plate. This would

alter the arm adjustment slightly but not enough

to be of any consequence.

CARRIAGE BEARING ADJUSTMENT

To test for looseness in the carriage, firmly grasp the car-

riage across the two carriage covers and apply a firm

rocking motion. Noticeable looseness may be adjusted as

follows:

1. Remove the left-hand carriage cover by removing two

attaching screws.

2. Loosen the yoke clamp arm (figure 27), lift up on the

swivel latch pin knob and rotate the yoke approximately

45 ° counterclockwise (when viewed from above) to posi-

tion the cutout portion of the yoke below the rear car-

riage bearing, thus providing room for the wrench on

the nut.

3. Working on the rear bearing (figure 27), loosen the nut

just enough to permit the eccentric screw to turn and

rotate it a partial turn (left or right) as required to take

up all looseness. Hold the eccentric screw and tighten

the nut. The adjustment is correct when there is no "'play'"

between the carriage and radial arm, yet the carriage

moves relatively free on the tracks.

ARM ASS¥.

11

Loading ...

Loading ...

Loading ...