Loading ...

Loading ...

Loading ...

E

Engine will not" .....

start or will run ....

only for a few

seconds after

starting. •

En_e will not

idle properly.

accelerate, lacks 2.

power, or dies 3.

under a load. 4.

5.

1.

excessively. 2.

' 3,

Engine runs hot. 1.

2.

3.

4.

Cutting Head stops 1.

under a load or does

not turn when en-

_e is accelerated.

or breaks while

cutting. .

Line welds onto spool

Line pulls back into

head or feeds

continuously._,_ ....i ::-_

.i

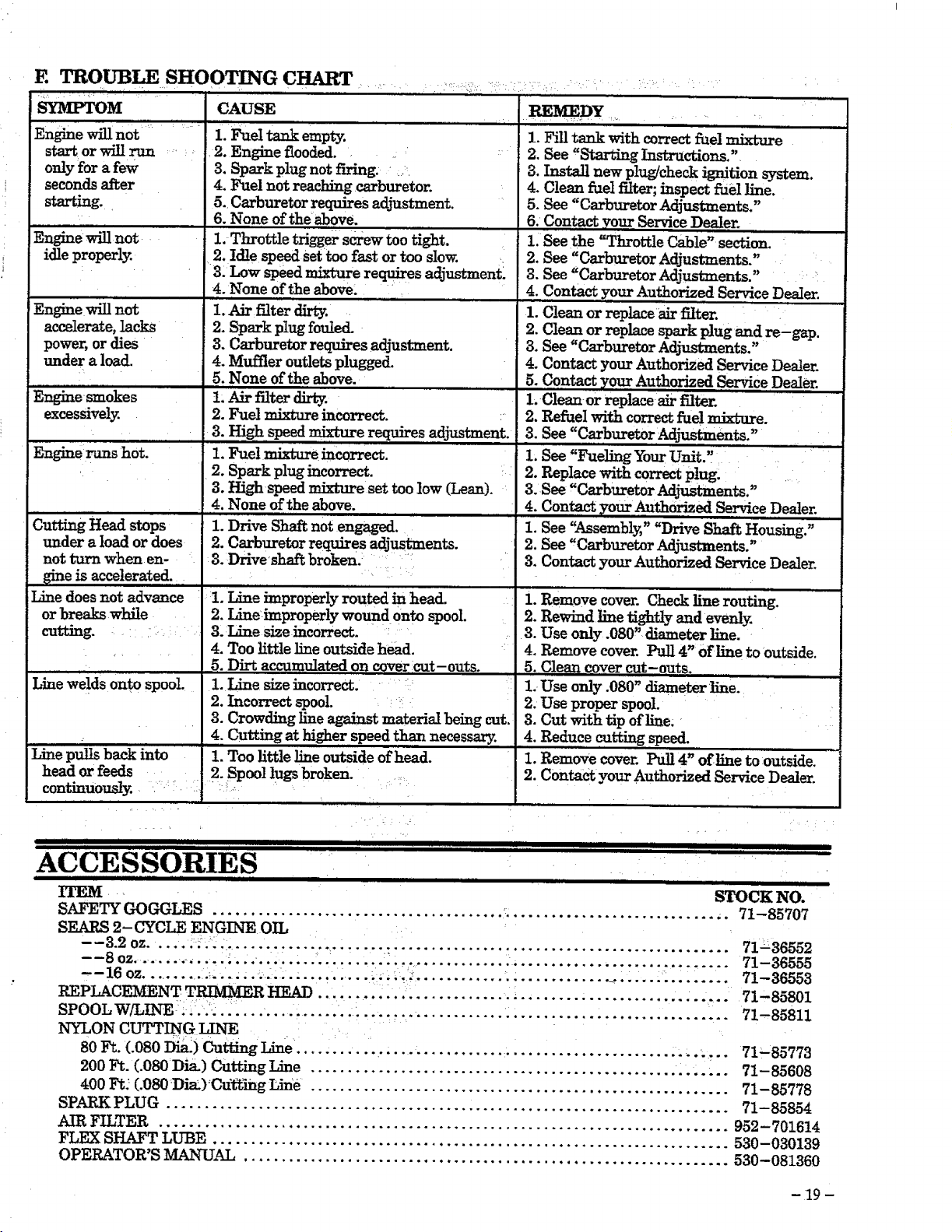

TROUB_ SHOOTING CHART

CAUSE

1.'Fuel tank empty. ......

2. Engine flooded ..... - '

3. Spark plug not firing. :;

4. Fuel not reaching carburetor.

5. Carburetor requires adjustment.

6. None of the above. ......

2. Idle speed Set too fast or too slow.

3. Low speed mixture redes adjustment _.

4-N °ne of the above. ...............

1. Air filter dirty.

Spark plugfouled.

Carburetor requires adjustment.

Muffler outlets plugged.

None of the above. ,

Air filter dirty.

Fuelmixtm'eincorrect. :-

Highspeed mixturerequires,,adjustment.

Fuel mi_._re "incorrect.

Spark plug incorrect.

High speed mixture set too low (Lean).

None of the above.

not .......

_JL

REMEDY

i. ii

1. Fill tank with correct fuel mixture

2. See "Starting Instructions."

3. Install new plug/check ignition system.

4. Clean fuel filter; inspect fuel line.

5. See "Carburetor Adjustments."

6. Contact your Service De_]er_

1. Seethe "Throttle Cable" section.

2. See "Carburetor Adjustments."

3. See "Carburetor Adjustments." : :

4. Contact ,your Authorized Service Dealer.

i. Clean or replace air filter. •

2. Clean or replace spark plug and re-gap.

3. See "Carburetor Adjustments."

4. Contact your Authorized Service Dealer.

5. Contact your Authorized Service De_ler.

1. Clean or replace air filter.

2. Refuel with correct fuel _e.

3. See Carburetor Adjustments. .........

1. See "Fueling'Your Umt."

2. Replace with correct plug ....

3. See "Carburetor Adjustments."

4. Contact your Authorized Service Dealer.

1. See "Assembly," "Drive Shaft Housing."

2. See "Carburetor Adjustments."

3. Contact your Authorized Service Dealer.

1. Remove cover. Check line routing.

2. Rewind line tightly and evenly.

3. Use only .080" dhmeter line.

4. Remove cover. Pull 4" 0fline to outside.

5. Clean cover cut-outs.

H,H

1. Use only .080" diameter line.

2. Use proper spool.

3. Cut with tip of line:

4. Reduce cutting speed...

1. Remove cover. Pull 4_ ofline to outside.

2. Contact your Authorized Service Dealer.

in head.

2. _e.improperly wound onto spool.

3. _e size incorrect.

4. Too little line outside head.

5. Dirt accumulated on cover icut-outs.

1. Line size incorrect. '

2. Incorrect spool. :-:

3. Crowding line against material being cut.

4. Cutting at higher speed thau necessary.

1. Too little line outside of head.

2. Spool lugs broken. :

ACCESSORIES "......."' "' ' '

I I III I I llilI ] il llIlll

ITEM IIII| I I II ] III ][ III]I II

STOCK NO.

SAFETY GOGGLES ....................................... :.............................. 71-85707

SEARS 2-CYCLE ENGINE OIL

--3.2 oz................................. _............................................. 71=36552

--8 oz................... ............................................................... 71-36555

--16 oz........................................ : ........................................... 71-36553

REPLACEMENT TRIMMER HEAD ........................................................ 71-85801

SPOOLW/LINE . ......................................................................... 71-85811

NYLON CUTTING LINE

80 Ft. (.080 Dia.) Curing Line ........... .......................................... ...... 71"85773

200 Ft. (.080 Di_) Cutting Line ................................................. .... :.. 71-85608

400 Ft. (.080 Dia:)_Cugting Line ........................................................ 71-85778

SPARK PLUG 71 - 85854

AIR FILTER ............................................................................ 952-701614

FLEX SHAFT LUBE ..................................................................... 530-030139

OPERATOR'S MANUAL ................................................................. 530-081360

- 19 -

Loading ...

Loading ...

Loading ...