Documents: Go to download!

User Manual

- User Manual - (English)

- Dimensions Guide - (English)

- Prop65 Warning Label - (English)

- HowTo Manual - (English)

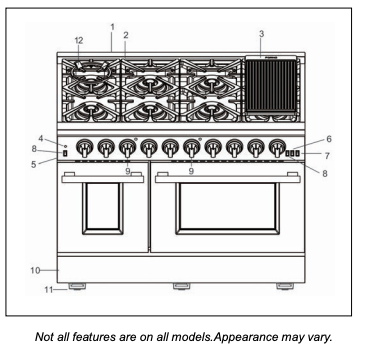

- Features of Your Range

- Installation Instructions

- Product Dimensions and Cabinets

- Cooktop Operation

- Simmer and Boil

- Burner Grates

- Oven Roasting

- Broiler Operation

- Oven Thermostat & Cooking times

- Care and Cleaning Recommendations

- Troubleshooting Tips

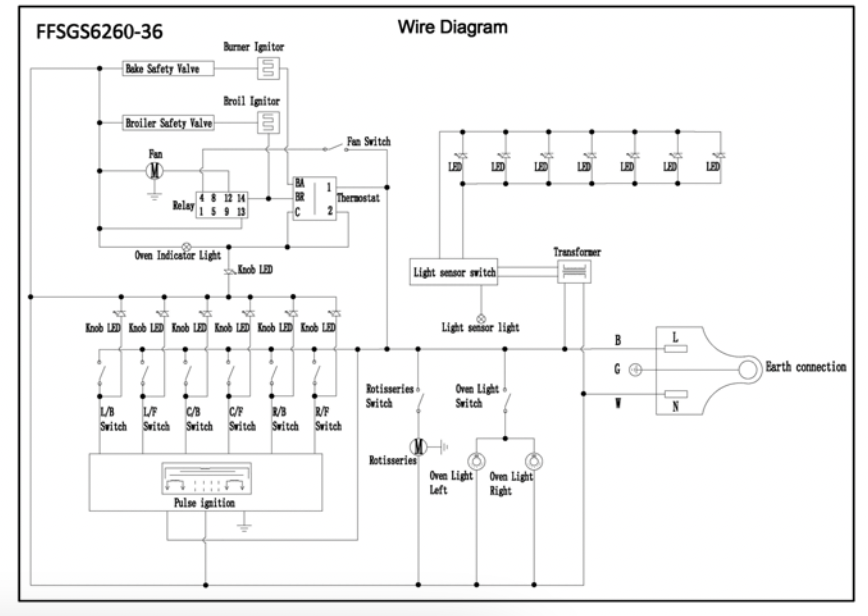

- Wire Diagram

Table of contents

INSTALLATION GUIDE SPECIFICATIONS, INSTALLATION, AND MORE

Models: FFSGS6260-30,FFSGS6260-48, FFSGS6260-36

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier. call the fire department.

Installation and service must be performed by a qualitied installer. service agency or the gas supplier.

Features of Your Range

Installation Instructions

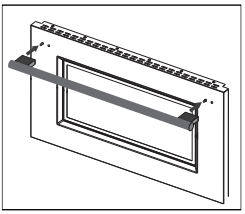

Door Handle Installation The door handle is not preinstalled. Find it in the front side of the whole package. Follow the illustrations below to install the door handle quickly and easiliy.

Warning Keep the square rubber mat of the handle mount to avoid scratching the oven door until this side is ready to be installed.

1. Remove the round black rubber mat from the inside door. and the square rubber mat on the handle mount.

2. Insert the screwdriver to the hole. and remove the screw nut from outside.

3. Install the handle with the exposed screw.

4. Repeat for the other side as step 1 to 3.

5. Put the round black rubber mats back to cover the two holes on the inside door.

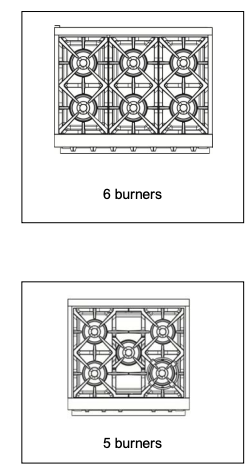

Cooktop Burner Grates Installation

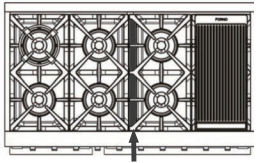

Remove the packing materials from the cooktop burner grates. Place the burner grates to the right position. Pay attention to the middle right grates as illustrated. as the thicker side should be in the left.

Put the griddle (only for FFSGS6260-48) and the wok support to the burner(s) you like to cook.

Oven Racks Installation

Electrical

Your range must be electrically grounded in accordance with local codes or, in the absence of local codes, in accordance with the National Electrical Code (ANSI/NFPA 70, latest edition). In Canada, electrical grounding must be in accordance with the current CSA C22.1 Canadian Electrical Code Part 1 and/or local codes.

The power supply must be the correct polarity. Reverse polarity will result in continuous sparking of the electrodes, even after flame ignition. If there is any doubt as to whether the power supply has the correct polarity or grounded, have it checked by a qualified electrician.

ELECTRICAL REQUIREMENTS Electrical Supply Service

Electrical Supply Grounded, 110/120 VAC, 60 Hz

Service 15 amp or 20 amp dedicated circuit

Receptacle 3-prong grounding-type

Power Cord 6' (1.8 m)

Warning Electrical Grounding Instructions: this cooking range is equipped with a three-prong (grounding) plug for your protection against shock hazard and should be plugged directly into a properly grounded three-pronged receptacle.

Do Not cut or removes the grounding prong from the plug.

Caution Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous operation. Verify proper operation after servicing.

Grounding

The power cord is equipped with a three-prong (grounding) plug which mates with a standard three-prong grounding wall receptacle to minimize the possibility of electrical shock hazard from the range.

All cord connected appliance shall include instructions relative to location of the wall receptacle and a warning to the user to disconnect the electrical supply before serving the appliance.

Where a standard two-prong wall receptacle is encountered. it is the responsibility and obligation of the customer to have it replaced with a properly grounded three-prong wall receptacle. Do not cut or remove the grounding prong from the power cord.

Gas Supply

Installation must comply with local codes or. in the absence of local codes. with the National Fuel

Gas Code. ANSI 2223.1 / NFPA 54. In Canada. installation must conform to the current natural

Gas Installation /code. CAN 1-1.1-M81 and with local codes where applicable.

This range has been design-certified according to ANS! Z21.1b-2012 latest edition.

GAS REQUIREMENTS

NATURAL GAS. WC

Supply Pressure 5'' (12.5 mb)

Minimum Supply Pressure 6''

Max Regulator Pressure 14" (34.9 mb). 0.5 psi (3.5 kPa)

LP. GAS WC

Supply Pressure 10" (25 mb)

Minimum Supply Pressure 11"

Max Regulator Pressure 14” (34.9 mb). 0.5 psi (3.5 kPa)

Warning Do not obstruct the flow of combustion air into the range and ventilation air away from the range.

Ventilation: it is recommended that the unit be operated with an oven head. vented exhaust hood of sufficient size and capacity.

Electric Power Supply Requirements

Pressure Regulator

Since service pressure may fluctuate with local demand. every gas cooking range must be equipped with a pressure regulator on the incoming service line for safe and efficient operation.

The pressure regulator shipped with the range has two female threads 34" NPT. The regulator shall be installed properly in order to be accessible when the appliance is installed in its final position.

Pressure regulator can withstand a maximum input pressure of 0.5 psi (3.5 kPa). and is set at 5" wc out let pressure.

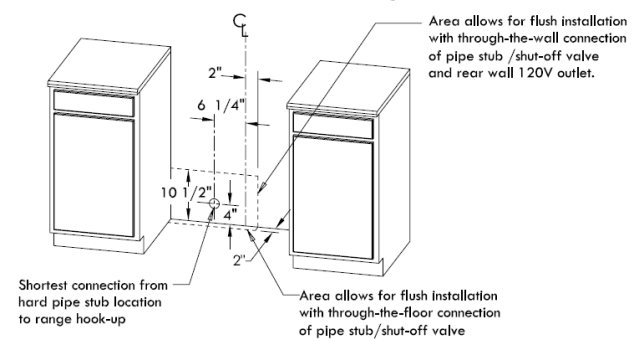

Gas Shut-off Valve

The supply line must be equipped with an approved external gas shut-off valve located near the range in an accessible location. Do not block access to the shut-off valve. Refer to the illustration below.

A 3/4" (19) ID gas supply line must be provided to the range. If local codes permit. a certified.

3' (.9 m) long. 1/2" (13) or 3/4" (19) ID flexible metal appliance connector is recommended to connect the unit’s 1/2" NPT female inlet to the gas supply line. Pipe joint compounds suitable for use with natural or LP gas should be used.

The appliance and its shut-off valve must be disconnected from the gas supply piping system during any pressure testing of the system at test pressures in excess of 0.5 psi (3.5 kPa). The appliance must be isolated from the gas supply piping system by closing its individual manual shutoff valve during any pressure testing of the system at test pressures equal to or less than 0.5 psi (3.5 kPa).

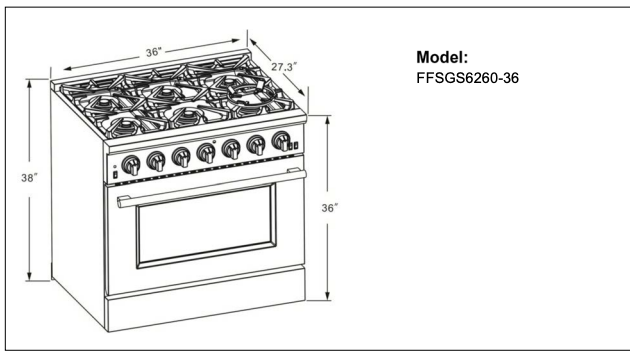

Product Dimensions and Cabinets

FFSGS6260-30

FFSGS6260-36

FFSGS6260-48

This range may be installed directly adjacent to existing countertop-height cabinets (36" or 91.5 cm from the floor).To achieve the best look. the cooktop should be level with the cabinet countertop. This can be accomplished by raising the unit using the adjustment spindles on the legs.

OPENING WIDTH W

30" Model 30" (762)

36" Model 36" (914) 48"

Model 48" (1219)

Exhaust Hood Installation

The bottom of the hood should be 30" min. to 36" above the countertop. This would typically result in the bottom of the hood being 66" to 72" above the floor. These dimensions provide safe and efficient operation of the hood.

After Installation:

1. Check ignition of cooktop burners.

2. Check the air shutter adjustment – sharp blue flame. with no yellow tipping or lifting flames.

3. Check ignition of oven burner.

4. Visually check tubular burner (oven burner) re-ignition to be sure both rows of burner ports are relighting each time.

5. Check for gas leaks at all gas connections (using a gas detector. never a flame).

6. Check oven bake and convection bake function.

Gas Conversion Operation

This cooking range can be used with LP gas and NG gas. Its shipped from the factory adjusted for use with NG(Nature Gas). Conversion nozzles are included. Follow the instruction shown below for gas conversion.

Warning Gas conversion shall be conducted by a factory- trained professional.Call the customer service hotline to identify a factory-trained professional near your home.

Warning Before carrying out this operation. disconnect the range from gas and electricity.

The gas conversion procedure for this range includes 8 steps:

1. Pressure regulator

2. Cooktop burners

3. Oven burner

4. Broil burner

5. Gas valves

6. Reconnect Gas and Electrical Supply

7. Air shutter oven burner

8. Installation of new rating label

The conversion is not completed if all 8 steps have not been concluded properly.

Before performing the gas conversion. locate the package containing the replacement nozzles shipped with every range.

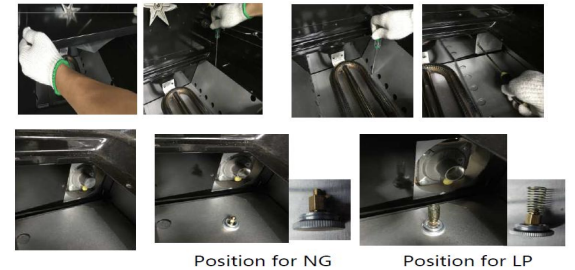

STEP 1: Pressure Regulator

To access the gas regulator. pull the range away from the cabinet wall. The gas regulator is located at the bottom right corner of the range.

Warning Electrical shock hazard can occur and result in injury or death. Disconnect electrical power to the range before servicing. Do not remove regulator or allow it to turn during servicing.

a. Unscrew the cap from the regulator.Do not remove the spring from the regulator.

b. Unscrew the insert from the cap and turn it over so the longer stem is facing the cap. Replace insert on the cap. Replace the cap on the regulator.

STEP 2: Cooktop Burners

a. Remove cooking grates, burner caps and inner burner rings.

b. Lift off outer burner heads and burner bases.

c. Remove the factory installed natural gas nozzles from the center of the nozzle holders using a 7mm socket wrench. Replace the LP nozzle in each nozzle holder. Tighten each nozzle until snug. Use caution not to over tighten

Caution Care should be taken when removing and replacing gas components. Use proper support to prevent damage to components.

Important Each nozzle has a number indicating its flow diameter printed on the body. Consult the table below for matching nozzles and burners.

Important: Save the nozzles removed from the range for future use.

STEP 3: Oven Burner

a. Remove 3 screws between the kick panel and the oven door. Hold the toe kick panel on both ends and slowly pull away towards the front.

b. Remove 2 screws which holding the nozzle bracket and locate the nozzle.

Replace with oven burner nozzle. size 1.32mm and tighten. Replace the nozzle bracket. aligning the new nozzle into the air shutter of the oven burner.

Repeat upon steps for 18”oven (48" ranges only).

STEP 4: Broil Burner

a. Remove 2 screws which fixing the nozzle bracket and locate the nozzle.

b. Using a 5/8”or 19mm open wrench. remove the gas line from the nozzle holder. Using a ½”open wrench. remove the nozzle from the orifice holder. Replace with 0.94 mm oven broiler nozzle.

STEP 5: Gas Valve

a. Remove control knobs.

b. Using a flat screwdriver. adjust main burner bypass jets toward to 1/4 circle for LP until the flame is normal.

STEP 6: Reconnect Gas and Electrical Supply

Leak testing of the range shall be conducted according to the installation instructions provided with the range.

Before operating the range after the gas conversion. always check for leaks with a soapy water solution or other acceptable method in at gas connections installed between the gas inlet pipe of the range. gas regulator. and the manual shut-off valve.

Warning DO NOT use a flame to check for gas leaks!

STEP 7: Air Shutter Oven Burner (no necessary)

The air shutter for the oven burner may need adjustment. especially if the unit has been converted for use with LP. The approximate flame height at the oven burner is one inch (distinctive inner blue flame).

To determine if the oven burner flame is acceptable:

a. With the kick plate removed. set the oven to bake at 350° F and observe the flame. If the flame yellow in color. increase the air shutter opening size. If the flame is blue and lifting away from the burner. reduce the air shutter opening size.

b. Turn off the oven and allow it to cool before adjusting the air shutter. To adjust. loosen the lock screw. reposition the air shutter and tighten the lock screw. Retest the burner by repeating the steps above. When the burner flame is a distinct blue colour and burning steadily. the air shutter is adjusted correctly.

STEP 8: Installation of New Rating Label

Record the model and serial number on the LP / Propane Rating serial plate provided in this kit.

The information can be obtained from the existing Rating / Serial plate. Place the new plate as close as possible to the existing Rating / Serial plate on the range.

Preparation

Before moving the range. protect any finished flooring and secure oven door(s) closed to prevent damage.

The oven door(s) can be removed to lighten the load or to fit the unit through a doorway. Only remove if necessary. Do not remove the griddle or any other component. Door removal should only be done by a certified installer or service technician.

Placement

Do not lift or carry the oven door by the door handle. The range has rear casters which allow for easy movement by lifting the front of the unit.

Use an appliance dolly to move the range near the opening. Remove and recycle packing materials. Do not discard the anti-tip bracket supplied with the range.

Leveling

Raise the range to the desired height by adjusting the legs. The legs can be adjusted by rotating the hexagonal leg clockwise to raise and counter clockwise to lower.

Anti-Tip Bracket

To prevent the range from tipping forward. the anti-tip bracket must be installed. Refer to the illustration on page 5.

Gas Supply Connection

All connections to the gas piping must be wrench-tightened. Do not overtighten or allow pipes to turn when tightening.

When all connections have been made. check that all range controls are in the “OFF” position and turn on the main gas supply valve.

If a flexible metal connector is being used. verify it is not kinked. then attach the gas supply line to the regulator on the range. Open the valve and check for leaks by placing a liquid detergent solution onto all gas connections. Bubbles around connections indicate a gas leak. If a leak appears. close the shut-off valve and adjust connections.

Leak testing of the appliance shall be conducted according to the manufacture’s instructions .Use some soap water (50% water and 50% soap) or a leak detector at all joints and connections to check for leaks in the system. Do not use a flame to check for gas leaks.

The appliance must be isolated from the building’s gas supply piping system by closing its individual manual shut-off valve during any pressure testing of the gas supply piping system at test pressure equal to or less than 0.5 psi (3.5kPa).

Getting Started

Before you start cooking. please take the following steps.

• Remove the exterior and interior packing.

• Remove the protective film on steel and aluminum parts.

• Clean the range thoroughly with hot water and a mild detergent. Rinse and dry with a soft cloth to remove any residual oil and grease left over from the manufacturing process.

• Check that surface burner components are assembled correctly.

• Furnish the interior of the oven by inserting the shelves and tray.

Cooktop Operation

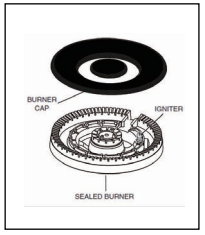

The burner design combines all burner parts in one assembly. The burner cap must be seated flatly on the burner. Refer to the illustration below.

Ignition

To light the cooktop burners, push and turn the appropriate control knob counter clockwise to a “Hi” position. You will hear a clicking noise –the sound of the electric spark igniting the burner. Once burner ignition has been achieved, turn the burner control knob to adjust the flame size. If the knob stays at “Hi”, it will continue to click.

NOTE: When one burner is turned to the “Hi” position, all the burners will spark. Do not attempt to disassemble or clean around any burner while another burner is on. Do not touch any burner cap, burner base, or igniter while the igniters are sparking.

Heat Settings:

Hi Ignites the burners.

Simmer Melting small quantities, steaming rice, warming food, melting chocolate or butter.

Low Melting large quantities.

Low-Medium Low-temperature frying, simmering large quantities, heating milk, cream sauces, gravies.

Medium Sautéing and browning, braising, pan-frying, maintaining slow boil on large quantities.

Medium-Hi High-temperature frying, pan boiling, maintaining slow boil on large quantities.

Hi Boiling liquid quickly, deep frying.

See other models: FFSGS6244-48 FFFFD1907-33SB FFRBI1805-33SB FRHRE5312-44 FFSGS6275-30

Caution Never leave pans on a high setting unattended. Be careful when cooking food in fat or grease; it can become hot enough to ignite.

Simmer and Boil

A smaller flame will give the best results when simmering. Small flames offer precise cooking performance for delicate foods. keeping food warm. melting chocolate or butter. and for cooking over low heat for long period of time.

The highest (larger) flame settings provide the maximum heat that is available on your range. This setting should be used for heavy cooking jobs such as boiling water and cooking pasts.

Flame Size

• When you select the flame size. watch the flame when you turn the knob.

• Any flame larger than the bottom of the cookware is wasted.

• The flame should be steady and blue in color. Foreign material in the gas line may cause an orange flame during initial operation.

Power Failure

• If the gas does not ignite within four seconds. turn off the valve and allow at least five minutes for any gas to dissipate. Repeat the lighting procedure.

• In the event of a power failure. the surface burners can be lighted manually. Hold a lighted match near a burner and turn the knob counter-clockwise to “HI”. After burner lights. turn knob to the desired setting.

Burner Grates

1. The grates must be properly positioned before cooking. Improper installation of the grates may result in scratching of the cooktop and / or poor combustion.

2. Do not operate the burners without a pan or utensil on the grates.

Griddle Operation (Only available on the 48”models)

Before Using the Griddle

1.Place the griddle to the position you need to cook.

2. Preheat the griddle for 10-12 minutes.

3. Butter or cooking oil can be added for more flavor. then place the food to cook.

Caution The surface of the griddle is hot after use. Please allow sufficient time for the griddle to cool prior to cleaning.

Cooktop Cleaning Tips

• To prevent the cooktop from discoloring or staining. clean cooktop after each use. and wipe up acidic or sugary spills as soon as the cooktop has cooled.

• The sealed burners of your range are not secured to the cooktop and are designed to be removed. Boil overs or spills will not seep underneath the cooktop. The burners should be cleaned after each use.

Oven Light

The oven light is controlled by a push switch on the control panel.

The light can be used while cooking or cleaning the oven.

Warning Check that power is disconnected from the electrical box before replacing the light bulb.

Allow the oven to cool completely. then unscrew the light cover and remove the light bulb by unscrewing it from the socket. Replace with a 40-watt halogen bulb.

Magic eyes

The red Magic Eyes will turn on automatic when the room becomes dark.

Oven Roasting

Some ranges are equipped with an automatic rotisserie for roasting.

The rotisserie feature allows for an even cooking and all-over browning of the meat while preventing the meat from cooking in its rendered grease. The rotisserie will turn the meat allowing it to baste itself while roasting.

Be sure that you have received the rotisserie accessories included with your unit.

(1) Rotisserie Spit – Rod

(2) Rotisserie Forks

Always use the broiling pan when using the rotisserie to catch the rendered grease and allow for easy access to the meat when putting in and removing the rotisserie spit – rod.

To use the rotisserie. preheat the oven to the desired temperature. Secure the meat to be cooked onto spit-rod using the rotisserie forks.

Insert the rotisserie spit-rod into the rotating assembly and select the desired rotisserie function (light on or light off).

Make sure that the baking / broiling tray is below the meat being cooked to avoid spills and to prevent possible flare-up of the oven flames.

Oven Roasting

Oven Baning Tips

1. Never cover any slots. holes or passages in the oven bottom or cover an entire rack with materials such as aluminum foil. Doing so blocks air flow through the oven and may cause carbon monoxide poisoning. The aluminum foil lining may also trap heat. causing a fire hazard.

Do not use aluminum foil on any porcelain surface. Doing so will damage the porcelain and affect its durability.

2. Position the racks before preheating the oven.

3. Reduce the oven temperature 25˚F (14˚C)when cooking in heat-proof glass or glass ceramic dishes.

Preheating

Allow the oven to preheat before placing food in the oven. Preheating is necessary for good results when baking cakes. cookies. pastry and breads.

Remove the broiler pan before preheating with the infrared broiler. Foods will stick on hot metal. To preheat. turn the “Oven’ selector knob to the “Broil” position. Wait for the burner to become hot. approximately 2 minutes.

Note: Condensation or fogging on the inside of the oven door glass is normal while preheating and it will usually evaporate by the end of the preheating cycle.

Oven Function

Natural Airflow Bake occurs when heat is transferred into the oven from the bake burners in the bottom of the oven cavity. Heat is then circulated by natural airflow. This is a traditional bake setting.

Convection Bake

Heat is transferred from the bake bumers in the bottom of the oven cavity to the oven cavity itself.

The convection fan at the rear of the oven then circulates it. This convection process provides a more even heat distribution throughout the oven cavity.

Using multiple racks is possible for large-batch baking. Convection cooking is faster. can be done at lower temperatures and provides more even temperatures than regular cooking.

Convection Roast

The convection fan circulates the heated air evenly over and around the food. Using the cover and broiler pan provided. heated air will be circulated over the around the food being roasted. The heated air seals in juices quickly for a moist and tender product. while at the same time creating a rich golden brown exterior. When convection roasting. it is important that you use the broiler pan for best convection roasting results. The pan is used to catch grease spills and has a cover to prevent grease splatters.

Convection Defrost

With temperature control off. the motorized fan in the rear of the oven circulates air. The fan accelerates natural defrosting of the food without heat. To avoid illness and food waste. do not allow defrost food to remain in the oven for more than two hours without being cooked.

Convection Dehydrate

With the temperature control on 175˚F. warm air is radiated from the bake burners in the bottom of the oven cavity and is circulated by a motorized fan in the rear of the oven. Over a period of time. the water is removed from the food by evaporation. Removal of water inhibits growth of microorganisms and retards the activity of enzymes.

Broiler Operation

Note: Door must be closed during broiling operation.

The broil burner is located at the top of the oven. This burner heats the metal screen until it glows. The glowing screen produces heat. searing the outside of broiled foods and sealing in juices. Broiling is a method of cooking tender cuts of meat directly under the broiler in the oven.

Oven broiling is done with the oven door closed. It is normal and even necessary to have some smoke to give the food a broiled flavor.

Setting Broil

The “Oven” selector knob controls the Broil feature. When broiling. heat radiates downward from the oven broiler for even coverage. The Broil feature temperature is 500˚F (260˚C).

Used together. the broil pan and insert allow dripping grease to drain and be kept away from the high heat of the oven broiler. DO NOT use the broil pan without the insert. DO NOT cover the broil pan insert with foil. The exposed grease could catch fire. To set the oven to Broil:

1. Place the broiler pan insert on the broiler pan. Then place the food on the broiler pan insert.

2. Arrange the interior oven rack and place the broiler pan on the rack. Be sure to center the

3. Turn the selector knob to Broil.

The oven indicator light will remain on until the selector knob is turned to the off position or the temperature control cycles off.

Position the rack at the correct level. The farther away the food is from the broiler. the more well done it will be inside. Preheating the oven is not necessary. Push in and turn the knob to BROIL.

Turn the food over at the halfway point. Always pull the rack out to the “stop” position before turning or removing food.

Oven Cleaning Tips

1. After each use. and once cooled. clean splatters and spills immediately.

2. Do not allow foods with a high sugar or acid content to remain on the oven cavity surface.

3. Use an oven cleaner to clean the oven cavity.

Oven Thermostat & Cooking times

The numbers printed on the control panel indicate the increasing oven temperature value (°F).

To regulate the temperature, set the desired number on the control knob indicator.

Note: The BROIL position is only to turn on the broil burner.

Cooking times can vary according to the type of food, its density and its size. It is advisable to watch when cooking for the first time and to check results since similar results are obtained when preparing the same dishes under the same conditions.same conditions.

Use the thermostat to control the temperatures, and control the time according to the cooking guides.

Care and Cleaning Recommendations

Stainless steel: Use a non-abrasive stainless steel cleaner and apply with a soft lint-free cloth. To

Burner grates Oven rack guides: Remove and place on a flat surface near the sink. Clean with hot water and mild detergent or paste of baking soda and water. Do not immerse in water. Towel dry.

Burner pan: Remove surface debris before cleaning to help speed up the cleaning process and decrease the chance of scratching the surface during cleaning. Using mild abrasive cleaners or spray degreasers, clean and rinse the surface and dry immediately to avoid streaking. To clean hard water stains, use white vinegar and water. Rinse and dry immediately.

Surface burners: Allow to cool. Use mild detergent or spray degreaser to clean. Rinse with water and towel dry.

Control knobs: Using a damp cloth, wipe with a mild detergent or spray degreaser; rinse and dry. Do not place in dishwasher.

Oven interior: Use mild abrasive cleaners, spray degreasers. Use a razor blade to gently lift baked on foods from oven cavity and window. For stubborn stains, spray with a mild abrasive cleaner or spray degreaser. Wash the entire oven cavity with soap and water to remove all cleaning chemicals.

Broiler pan: To clean the upper rack, use mild detergent and a scouring pad. Rinse and dry. To clean the bottom pan, discard grease and wash with hot water and mild detergent. Rinse and dry. The stainless steel upper rack is dishwasher safe. However, do not place the porcelain-coated rack or pan in dishwasher.

Troubleshooting Tips

Before you call for service

Range does not operate:

- Check that power is on.

- Check that electrical power to range and home circuit breaker is on.

Burners Do Not Light Or Spark Randomly:

- Electrical plug is not plugged into a live power outlet.

- Gas supply not turned on.

- Burner parts not replaced correctly.

- Holes in the simmer rings or slits in the burner rings are clogged.

- Clogged nozzles, or wet burners or electrodes.

- A fuse in your home may be blown or circuit breaker tripped.

Burners Have Yellow Or Yellow-Tipped Flames:

- Burner parts not replaced correctly.

- A. Yellow flames: Call for service.

- B. Yellow tips on outer cones: Normal for propane (LP) gas.

- C. Soft blue flames: Normal for natural gas.

- If burner flames look like (A), call for service. Normal burner flames should look like (B) or (C), depending on the type of gas.

Burner Flames Very Large Or Yellow

- The range may be connected to the wrong fuel type. Contact the person who installed your range or made the conversion.

Burner Flames Contain Orange Flickers

- Airborne dust; cool-mist humidifier; debris on or inside burner.

Oven Lights Do Not Work

- The light bulb is defective. Replace the bulb.

Oven Racks Are Hard To Slide

- Do not spray with a cooking spray or other lubricant sprays. See Full extension oven racks in the Care and Cleaning section.

Food Does Not Bake Or Roast Properly

- The oven controls are improperly set. See the Baking or Roasting section.

- Oven not preheated for a long enough time.

- Incorrect cookware or cookware of improper size being used.

- Racks in the wrong position. See the Baking or Roasting section.

- Use a foil tent to slow down browning during roasting.

- Oven thermostat needs adjustment. See the Oven thermostat adjustment section.

Food Does Not Broil Properly

- This model is designed for closed door broiling only. Close the door. Always broil with the door closed.

- The oven controls are not set at BROIL. See the Broiling section.

- Improper rack position.

- Cookware is not suited for broiling. Use the broiling pan and rack that came with your oven.

- Aluminum foil used on the broiling pan and rack has not been fitted properly and slit as recommended.

Oven Temperature Too Hot Or Too Cold

- Oven thermostat needs adjustment. See the Oven thermostat adjustment section.

Steam From The Vent

- When using the convection mode, it is normal to see steam coming out of the oven vent. As the number of racks or amount of food being cooked increases, the amount of visible steam will increase.

Burning Or Oily Odor Emitting From The Vent

- This is normal in a new oven and will disappear in time.

Strong Odor

- This is temporary. An odour caused by the insulation around the inside of the oven is normal for the first few times the oven is used.

Convection Fan Not On All The Time

- The convection fan (depending on the function you are using) may cycle on and off until the function is over or the door is opened for optimized performance.

- This is normal. In addition, the convection fan may cycle in the clockwise and counter clockwise direction until the function is over or the door is opened.

Condensation Or Fogging On The Inside of the Door Glass

- Condensation or fogging on the inside of the oven door glass is normal during the preheating of the oven and will evaporate usually by the end of the preheating cycle.

Cracking Or Popping Sound During Cleaning This is normal.

- This is the sound of the metal heating and cooling during both the cooking and cleaning functions.

Excessive Smoking Occurs During Cleaning

- The oven is heavily soiled. Turn the Oven Mode Selector and the Temperature knobs to OFF. Open the windows to rid the room of smoke. Wait until the locked door indicator light goes off. Wipe up excess soil and do the cleaning again.

Wire Diagram